Multifunctional biological drying conditioner and preparation method thereof

A biological drying and multi-functional technology, applied in biological sludge treatment, chemical instruments and methods, dehydration/drying/thickened sludge treatment, etc., can solve the problem of polyethylene glycol losing heat storage, biochar hole collapse, Biochar loss and other problems, to achieve the effect of maintaining heat, prolonging the high temperature period, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

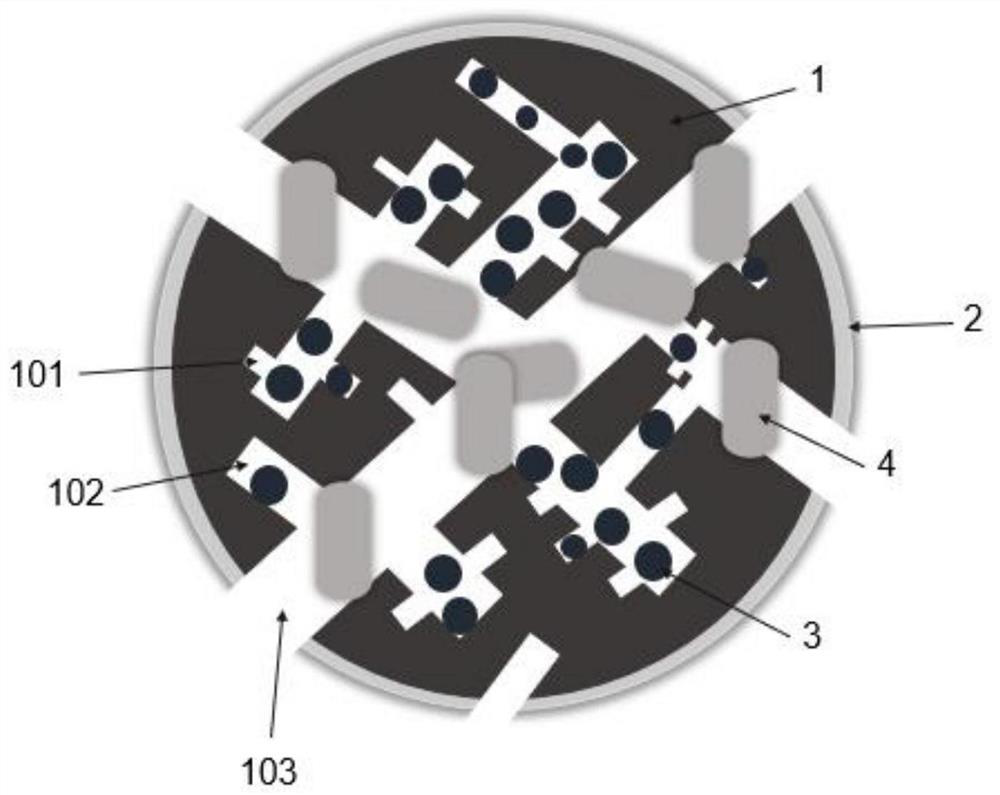

Image

Examples

Embodiment 1

[0047] A preparation method of a multifunctional biological drying conditioner:

[0048] Take a certain amount of dewatered sludge, place it in an oven at 105°C, dry it for 24 hours, and weigh it several times until it reaches a constant weight. Use an electronic balance to accurately weigh 50g of dried sludge samples, grind them evenly, add 10ml of coal tar, and put them into a granulator for granulation. Put the granulated sludge into a rotary tubular pyrolysis furnace, pass in a mixed gas (8vt% oxygen, 92vt% nitrogen), rotate at a speed of 10r / min, and pyrolyze at 900°C for 2h, and place the prepared porous carbon spheres in a dissolved 10g In dehydrated ethanol of polyethylene glycol (analytically pure, molecular weight 10000), immerse porous carbon spheres, put them in a suction filter bottle after standing and blending for 12 hours, start the vacuum pump, and filter for 30 minutes under the condition of a vacuum degree of 0.1MPa Then take out the sample and place it on ...

Embodiment 2

[0051] Take a certain amount of dewatered sludge, place it in an oven at 105°C, dry it for 24 hours, and weigh it several times until it reaches a constant weight. Use an electronic balance to accurately weigh 50g of dried sludge samples, grind them evenly, add 10ml of coal tar, and put them into a granulator for granulation. The sludge after granulation is put into a rotary tube type pyrolysis furnace, and a mixed gas (8vt% oxygen, 92vt% nitrogen) is introduced, and the rotating speed is 10r / min, and it is pyrolyzed at 900°C for 2h, and polyethylene glycol with a molecular weight of 6000 and Polyethylene glycol with a molecular weight of 10,000 was mixed according to a weight ratio of 1:1, and 10 g of the mixed polyethylene glycol was accurately weighed and dissolved in absolute ethanol, and the porous carbon spheres were immersed in it, and placed in a pump after standing and blending for 12 hours. In the filter bottle, start the vacuum pump, perform suction filtration for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com