Method for preparing porous nano silicon dioxide pellets under neutral condition

A technology of nano-silica and neutral conditions, applied in the direction of silica, silicon oxide, nanotechnology, etc., can solve problems such as difficult to obtain porous silica, achieve high mechanical strength, uniform dispersion, and increase material strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Formation of imidazolium ionic liquid micelles: Weigh 1.720g of 1-dodecyl-3-methylimidazolium chloride salt (concentration about 40mM) and add it to 150mL water and stir to make it self-assemble to form micelles. The schematic diagram is as follows figure 1 shown;

[0037] Weigh 0.123g trisodium phosphate (concentration about 5mM) into the above solution, add an appropriate amount of phosphoric acid to adjust the pH of the solution to 7.0; Stirring and reacting for 120 minutes, a white precipitate precipitated out, centrifuged at 8000 rpm, and the product was dried in an oven at 80°C, and then calcined in a muffle furnace at 600°C for 4 hours to obtain porous silica pellets.

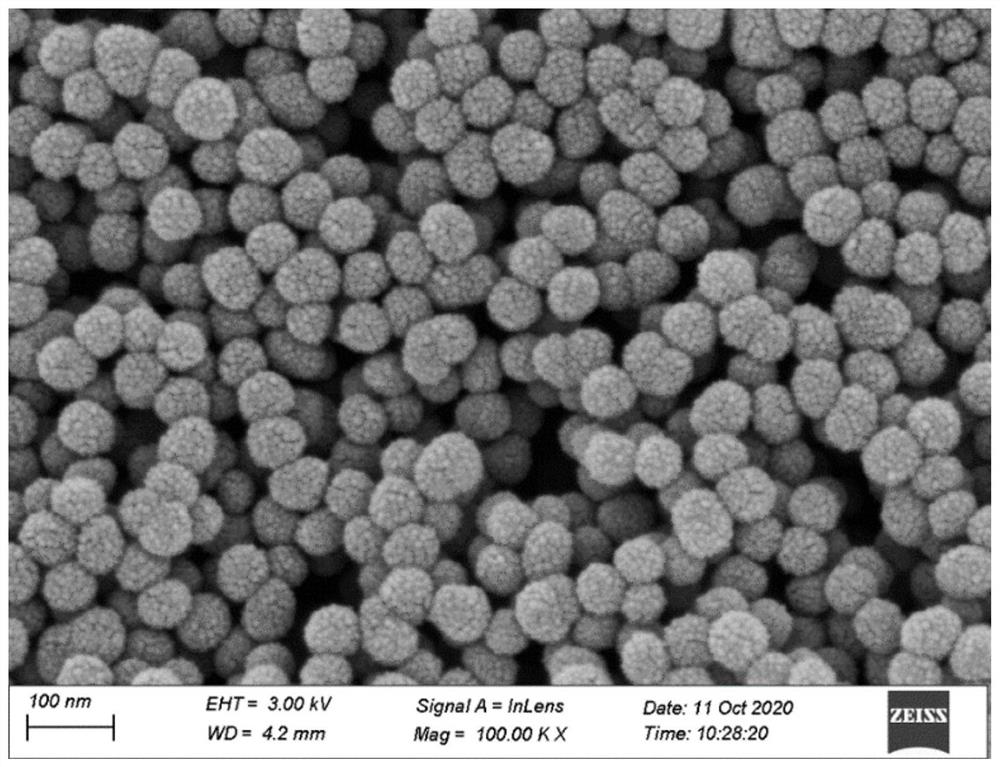

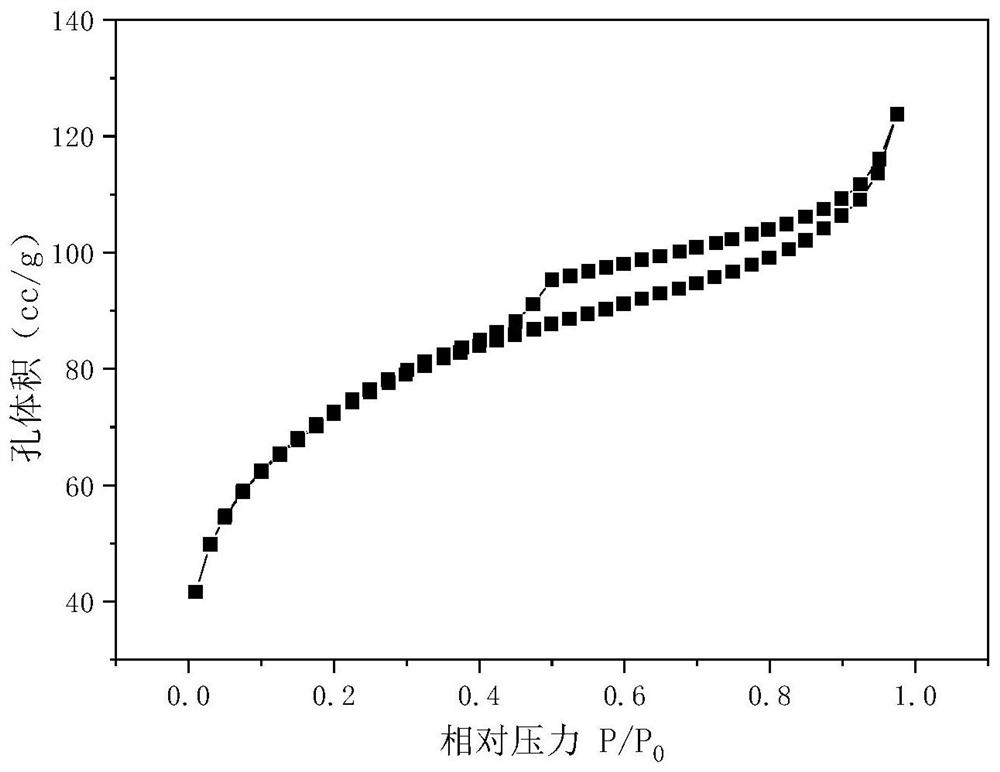

[0038] The interaction between the imidazole group and the phosphate radical can make silica grow on the micelles formed by the imidazole ionic liquid, and the uniformly dispersed bead size of the preparation is about 60nm ( figure 2 ), BET experiments show that the pore diameter is about 0.38nm...

Embodiment 2

[0040] Formation of imidazolium ionic liquid micelles: Weigh 1.720g of 1-dodecyl-3-methylimidazolium chloride salt (concentration about 40mM) into 150mL water and stir to make it self-assemble to form micelles;

[0041] Weigh 0.246g trisodium phosphate (concentration about 10mM) into the above solution, add an appropriate amount of phosphoric acid to adjust the pH of the solution to 7.0; slowly add 3.3mL tetraethyl orthosilicate into the solution, 60°C, 150rpm Stirring and reacting for 120 minutes, a white precipitate precipitated out, centrifuged at 8000 rpm, and the product was dried in an oven at 80°C, and then calcined in a muffle furnace at 600°C for 4 hours to obtain porous silica pellets.

[0042] The interaction between the imidazole group and the phosphate radical can make silica grow on the micelles formed by the imidazole ionic liquid, and the uniformly dispersed bead size of the preparation is about 260nm ( Figure 4 ), BET experiments show that the pore diameter is ...

Embodiment 3

[0044] Formation of imidazolium ionic liquid micelles: Weigh 1.720g of 1-dodecyl-3-methylimidazolium chloride salt (concentration about 40mM) into 150mL water and stir to make it self-assemble to form micelles;

[0045] Weigh 0.246g of trisodium phosphate (concentration about 10mM) in the above solution, add an appropriate amount of phosphoric acid to adjust the pH of the solution to 7.0; add 3.3mL of tetraethyl orthosilicate to the solution in equal amounts in 2 steps (per Add 1.1mL in 2h, 3 times in total), 95°C, 150rpm stirring reaction for 120min, a white precipitate precipitated, 8000rpm centrifuge, the product was dried in an oven at 80°C, and then calcined in a muffle furnace at 600°C for 4h to obtain porous silica pellets .

[0046] The interaction between the imidazole group and the phosphate radical can make silica grow on the micelles formed by the imidazole ionic liquid, and the uniformly dispersed bead size of the preparation is about 550nm ( Figure 6 ), BET exp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com