A treatment method for roadbed hazards

A roadbed and filling technology, applied in chemical instruments and methods, soil protection, infrastructure engineering, etc., can solve problems such as increased deformation, decreased strength, and impact on engineering performance of saline soil, achieving interaction enhancement and improvement Water retention and the effect of reducing shrinkage cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

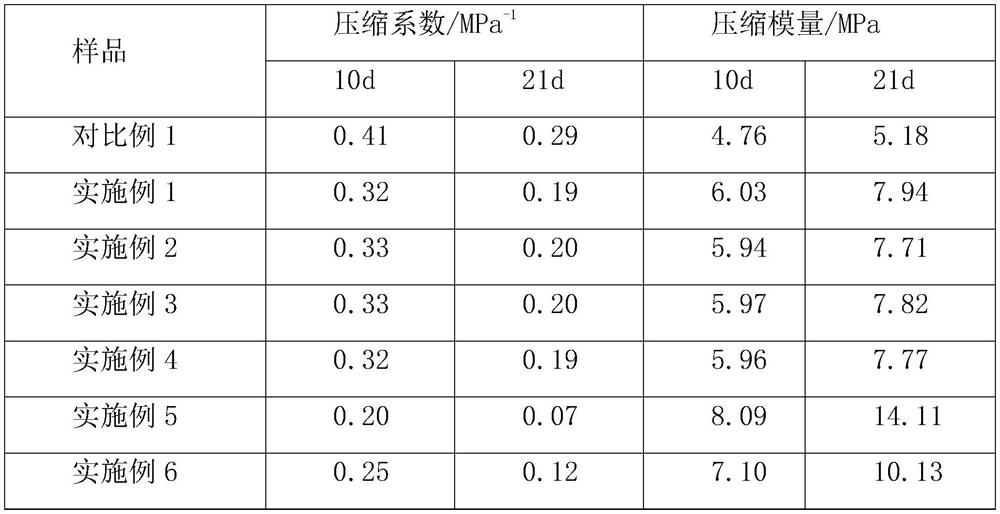

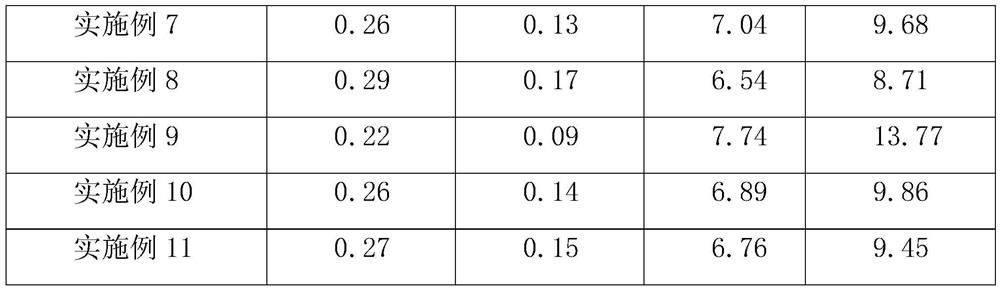

Embodiment 1

[0037] The soluble calcium salt used in the examples of the present invention is a mixture of calcium chloride, calcium dihydrogen phosphate, calcium carbonate, and calcium iodide, and the mass ratio of the four is 1:1:1:1.

[0038] The preparation method of microbial preparation used in the embodiment of the present invention:

[0039] Helicobacter pylori was inoculated in the culture medium (Bruchner's broth medium with 10% inactivated horse serum, with or without 3'-methoxy apigenin 0.2g / L), in a medium containing 5% O 2 , 10% CO 2 and 85%N 2 Under micro-aerobic conditions, cultured at 37°C for 72h, the density was 4×10 9 CFU / mL of bacterial liquid. Helicobacter pylori is a public strain, commercially available, and the deposit number is ATCC 43504.

[0040] The saline soil used in the embodiment of the present invention is chlorine saline soil, the water content of the soil is 18wt%, and the particle size is 0.15-0.20 mm.

[0041] Example 1:

[0042] Preparation of m...

Embodiment 2

[0051] The difference between the preparation of modified acrylate copolymer emulsion and Example 1 is: the molar ratio of MMA, BA, AA and entecavir impurity SSS in the mixed monomer is 1:0.4:0.3:0.2; the amount of emulsifier is the mass of the mixed monomer 3.7%; the amount of the initiator is 0.65% of the mass of the mixed monomers.

[0052] The raw materials of filling soil for prevention and treatment of roadbed hazards include, in parts by weight, 110 parts of saline soil, 7 parts of modified acrylate copolymer emulsion prepared in this embodiment, 10 parts of microbial preparations, 20 parts of soluble calcium salt, 15 parts 1 part urea, 2.5 parts polypropylene fiber.

[0053] A treatment method for roadbed hazards is the same as in Embodiment 1.

Embodiment 3

[0055] The difference between the preparation of the modified acrylate copolymer emulsion and Example 1 is that the molar ratio of MMA, BA, AA and entecavir impurity SSS in the mixed monomer is 1:0.25:0.35:0.28; the amount of emulsifier is the mass of the mixed monomer of 4.36%; the amount of the initiator is 0.57% of the mass of the mixed monomers.

[0056] The raw materials of filling soil for prevention and treatment of roadbed hazards include, in parts by weight, 95 parts of saline soil, 4 parts of modified acrylate copolymer emulsion prepared in this embodiment, 15 parts of microbial preparations, 32 parts of soluble calcium salt, 28 parts 1 part urea, 5 parts polypropylene fiber.

[0057] A treatment method for roadbed hazards is the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com