Potassium manganate/carbon composite material with core-shell structure and preparation method and application thereof

A technology of carbon composite materials and structural potassium manganate, which is applied in the preparation/purification of carbon, manganate/permanganate, structural parts, etc., and can solve the problems of poor conductivity stability and hindering the application of manganese-based cathode materials , to achieve the effect of improving conductivity, improving cycle stability, and excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

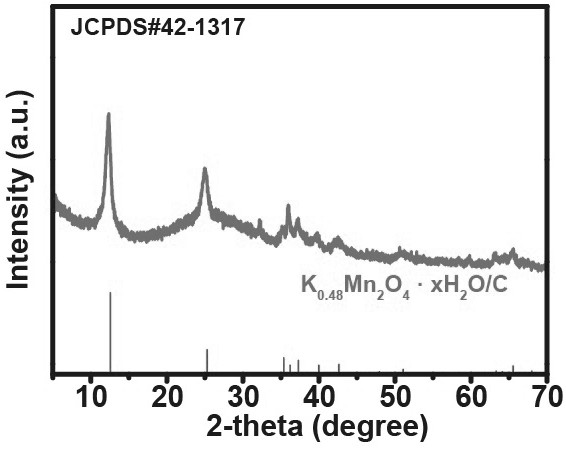

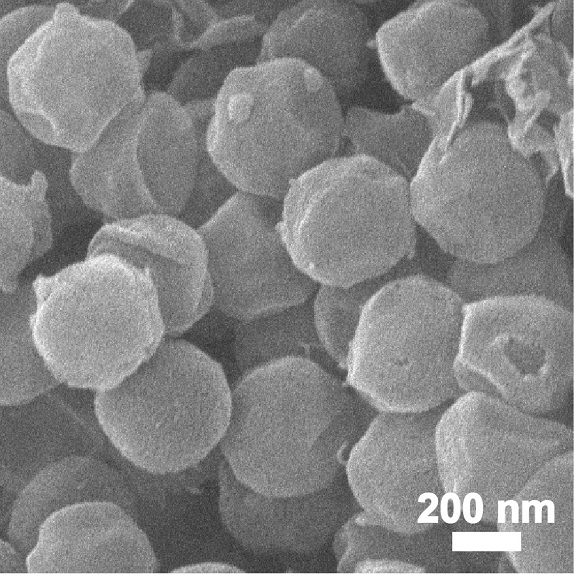

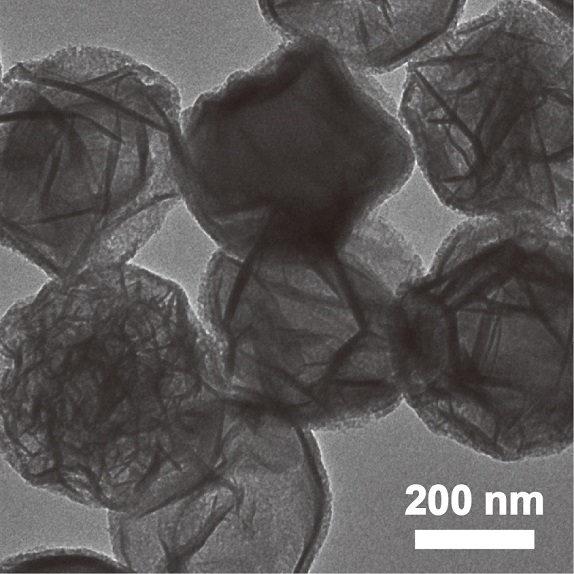

[0041] Example 1: Prepared core-shell structure potassium manganate / carbon composite material (silicon source is tetraethyl orthosilicate)

[0042] Preparation technology flow chart as figure 1 As shown, mix 70mL of ethanol, 10mL of deionized water and 3mL of ammonia water (25%), then add 6mL of ethyl orthosilicate, stir for 15min, add 0.4g of resorcinol, stir for 30min, then add 0.56mL of Forol Marlin solution was stirred continuously at room temperature for 24 h at last, and the resulting precipitate was centrifuged five times with deionized water and ethanol, and o After drying at C for 10 h, orange SiO was finally obtained 2 @resorcinol−formaldehyde (RF) oligomers (SiO 2 @RF). The SiO obtained in the first step 2 @RF at 750 o Carbonization at C for 5h to obtain SiO 2 @C Composite. MnCl 4 • 4H 2 O (0.4 mmol) and NH 4 Cl (20 mmol) was dissolved in 30 mL water at room temperature to obtain solution A, 50 mg of SiO 2 @C is ultrasonically dispersed into 20mL water to...

Embodiment 2

[0045] Example 2: Prepared core-shell structure potassium manganate / carbon composite material (silicon source is propyl orthosilicate)

[0046] Preparation technology flow chart as figure 1 As shown, mix 70mL of ethanol, 10mL of deionized water and 3mL of ammonia water (25%), then add 3.46mL of propyl orthosilicate, stir for 15min, add 0.4g of resorcinol, stir for 30min, then add 0.56mL of formalin solution, and finally stirred continuously at room temperature for 24 h, and the resulting precipitate was centrifuged five times with deionized water and ethanol, and o After drying at C for 10 h, orange SiO was finally obtained 2 @resorcinol−formaldehyde (RF) oligomers (SiO 2 @RF). The SiO obtained in the first step 2 @RF at 750 o Carbonization at C for 5h to obtain SiO 2 @C Composite. MnCl 4 • 4H 2 O (0.4mmol) and NH 4 Cl (20 mmol) was dissolved in 30 mL water at room temperature to obtain solution A, 50 mg of SiO 2 @C is ultrasonically dispersed into 20mL water to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com