MXene composite membrane modified electrode and electrochemical identification of MXene composite membrane modified electrode on methionine enantiomer

A technology for modifying electrodes and composite membranes, which is applied in the fields of electrochemical variables of materials, scientific instruments, and material analysis through electromagnetic means, and can solve problems such as insufficient exposure of catalytic active sites, limited development of hydrotalcite-like in depth, and poor conductivity , to achieve the effect of increasing active interface sites, improving electrochemical performance and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

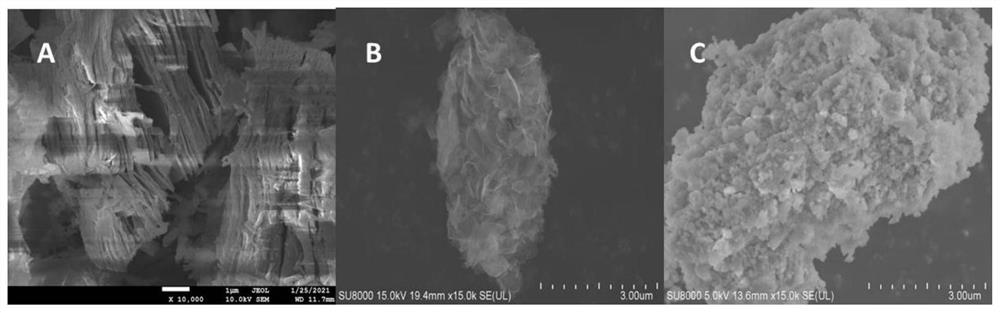

[0030] (a) Preparation of MXene materials

[0031] Prepare 30mL of 6M HCl solution in a Teflon beaker, add 1.98g LiF, mix well; slowly add 3g Ti 3 AlC 2 powder, keep stirring during the addition process; keep the reaction mixture at 40°C for 45h, centrifuge and wash until the pH of the supernatant is 6; freeze-dry to obtain Ti 3 C 2 T x MXene, hereinafter referred to as MXene;

[0032] (b) Preparation of MXene@LDHNS

[0033] Disperse MXene (0.04g) into 10mL deionized water, sonicate it for 2h to peel it off, centrifuge at 3500rpm for one hour, discard the precipitate, and mix the obtained upper layer solution with Co(NO 3 ) 2 ·6H 2 O(0.291g), Al(NO 3 ) 3 9H 2 O (0.1875g) and ammonium fluoride (0.1675g) were dispersed in 55mL of deionized water and stirred evenly; 1M ammonia water (4.5mL) was added dropwise to the mixed solution; the suspension was stirred at room temperature for 1.5h and aged for 2.5 h The resulting MXene@LDHNS was washed with distilled water and et...

Embodiment 2

[0039] (a) Preparation of MXene materials

[0040] Prepared according to the method and conditions of step (a) in Example 1;

[0041] (b) Preparation of MXene@LDHNS

[0042] Prepared according to the method and conditions of step (b) in Example 1;

[0043] (c) Preparation of MXene@LDHNS / CMCD

[0044] Prepared according to the method and conditions of step (c) in Example 1

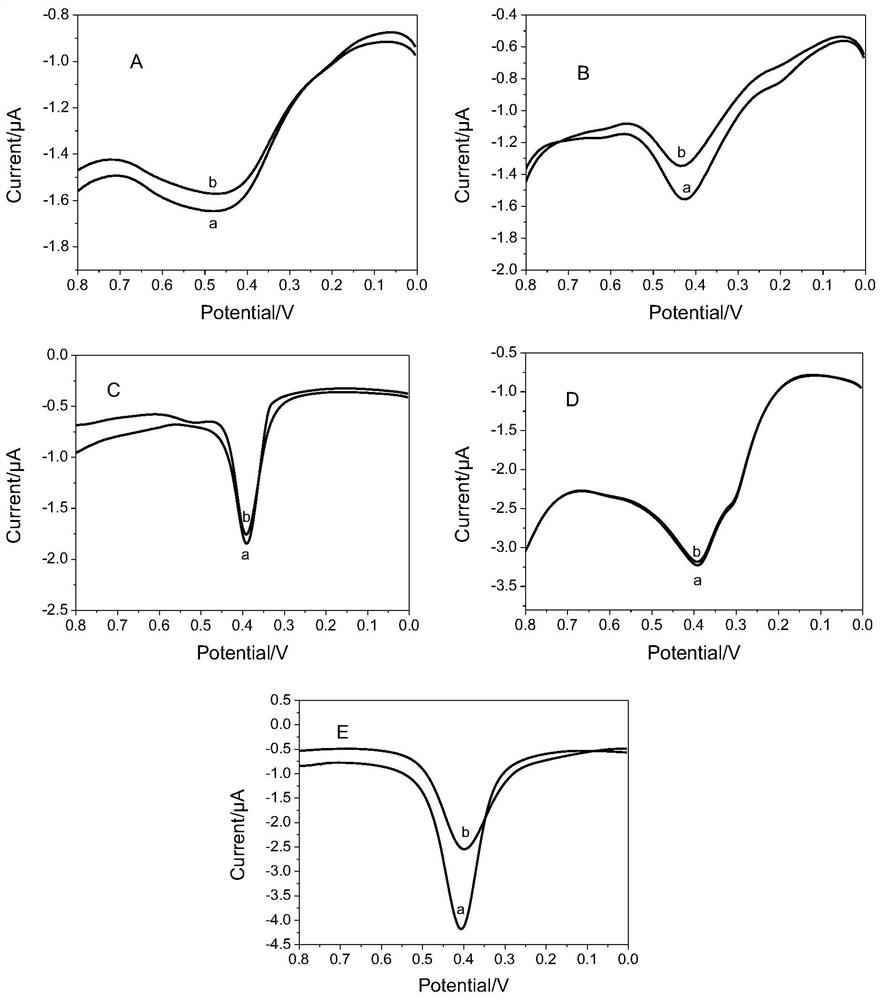

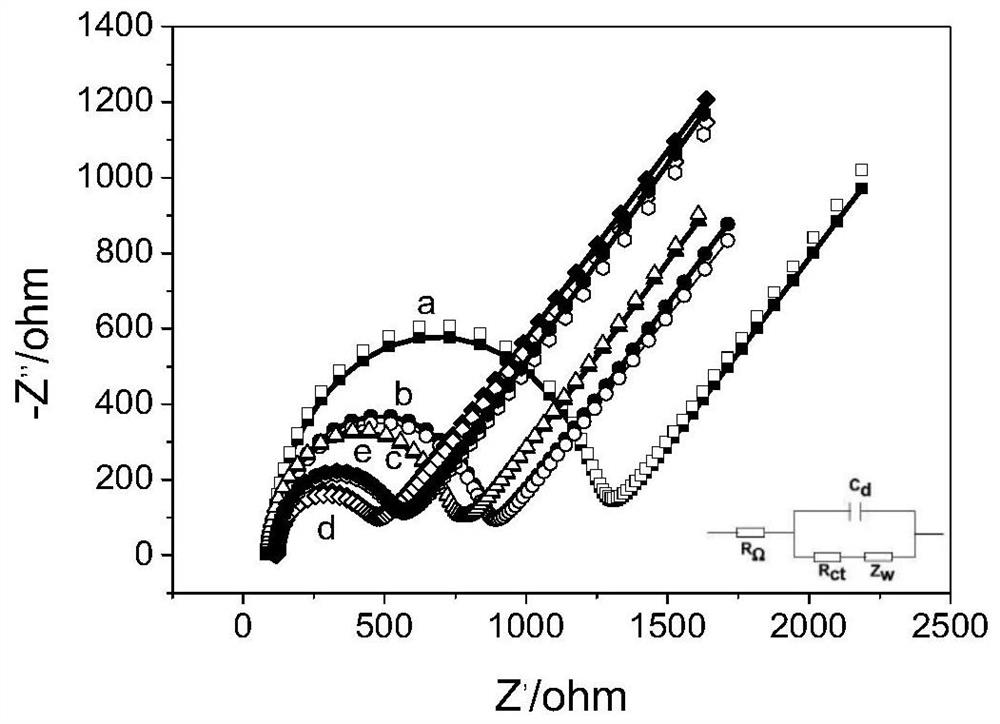

[0045] (c) Preparation of MXene@LDHNS / CMCD composite modified GCE

[0046] Grind and polish the base electrode into a mirror surface, then ultrasonically clean it with ultrapure water, and dry it naturally at room temperature to obtain the processed GCE; ultrasonically disperse the MXene@LDHNS / CMCD composite material prepared in step (c) in deionized water, and prepare the concentration 1 mg / mL dispersion liquid, take 2 μL of the dispersion liquid and drop-coat it on the surface of the GCE treated in step (d), and let it dry naturally at room temperature to obtain the MXene@LDHNS / CMCD composite membrane...

Embodiment 3

[0048] (a) Preparation of MXene materials

[0049] Prepared according to the method and conditions of step (a) in Example 1;

[0050] (b) Preparation of MXene@LDHNS

[0051] Prepared according to the method and conditions of step (b) in Example 1;

[0052] (c) Preparation of MXene@LDHNS / CMCD

[0053] Prepared according to the method and conditions of step (c) in Example 1

[0054] (c) Preparation of MXene@LDHNS / CMCD composite modified GCE

[0055] Grind and polish the base electrode into a mirror surface, then ultrasonically clean it with ultrapure water, and dry it naturally at room temperature to obtain the processed GCE; ultrasonically disperse the MXene@LDHNS / CMCD composite material prepared in step (c) in deionized water, and prepare the concentration 1 mg / mL dispersion liquid, take 8 μL of the dispersion liquid and drop-coat it on the surface of the GCE treated in step (d), and let it dry naturally at room temperature to obtain the MXene@LDHNS / CMCD composite membrane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com