Method for constructing LiF protection layer on three-dimensional lithium-carbon composite material and application of LiF protection layer

A carbon composite material and composite material technology, applied in the field of electrodes, can solve the problems of cumbersome operation, limited application, cumbersome preparation process, etc., and achieve the effects of energy saving, easy operation and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] In the present invention, the preparation method of the fluorine-containing organic binder solution preferably includes:

[0066] The fluorine-containing organic binder powder is mixed with a solvent to form a solution.

[0067] In the present invention, the fluorine-containing organic binder is preferably selected from polyvinylidene fluoride (PVDF), hexafluoropropylene (HFP), polyvinyl fluoride (PVF), polytetrafluoroethylene (PTFE), polyvinylidene One or more of vinyl fluoride-hexafluoropropylene copolymer (PVDF-HFP) and ethylene-tetrafluoroethylene copolymer (ETFE); comprehensive consideration of hydrogen content, fluorine content, solubility, cohesiveness, etc. , more preferably PVDF-HFP.

[0068] In the present invention, the mass fraction of the organic binder solution is preferably 5-20%.

[0069] In the present invention, it is preferable to place the fluorine-containing organic binder solution in a jar and seal the bottle mouth with a parafilm, and place it o...

Embodiment 1

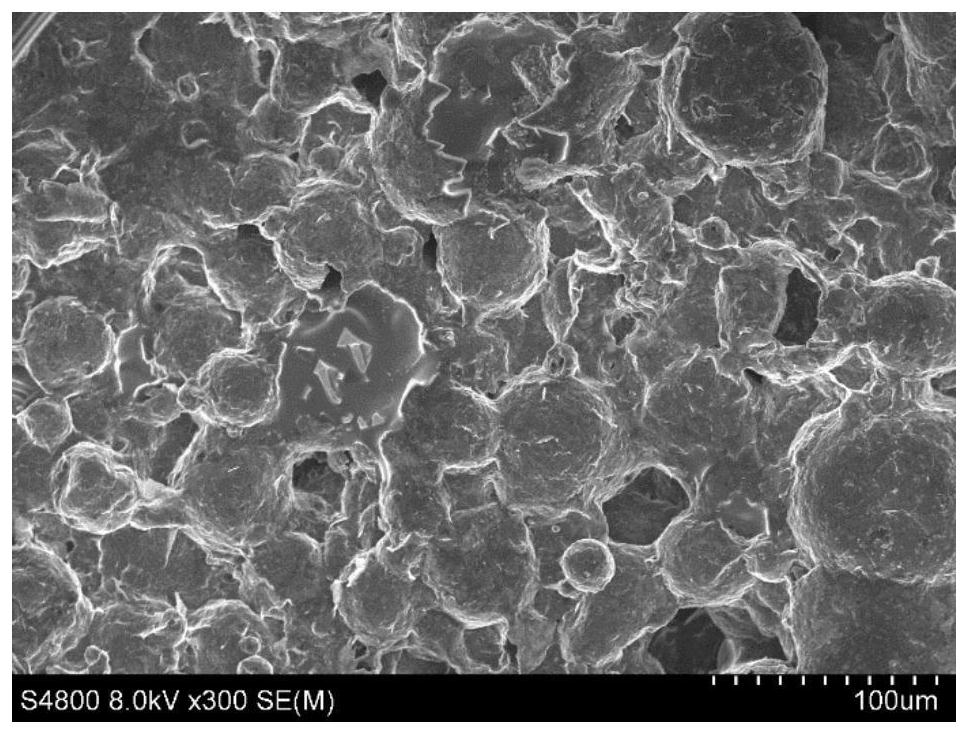

[0139] Weigh 0.15g dry graphene former powder and put it into a homogenizing cup, add 4g 5wt% PAN solution (polyacrylonitrile solution) thereto, and then add 2g NMP dropwise. Cover the cup and seal the mouth of the cup with a sealing film, homogenize with a homogenizer, the speed is as follows: 1000rpm-30s, 2000rpm-120s, 1200rpm-60s, 2500rpm-120s, 1000rpm-40s; Transfer to an inert gas glove box, add 1.2g of stable lithium metal powder (LMP) in the glove box and seal the cup mouth with parafilm again. After adding the lithium powder, continue to homogenize the mixture once with a homogenizer at the following speeds: 1000rpm-30s, 2500rpm-120s, 1000rpm-30s; after two times of homogenization, the final metal lithium / graphene composite material slurry is obtained.

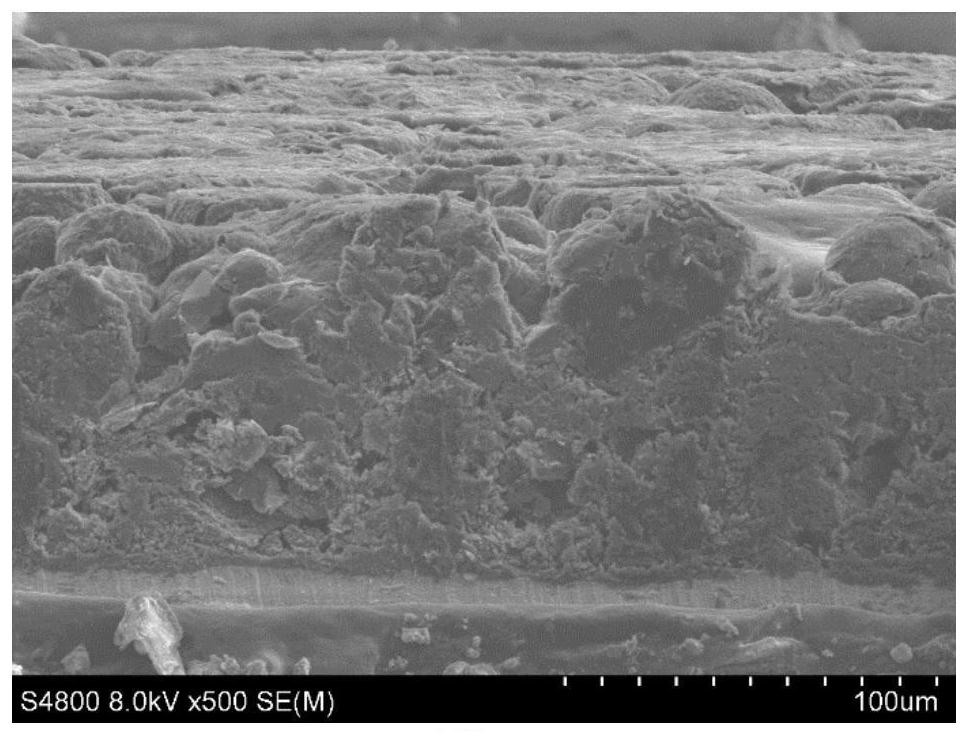

[0140] The coating process is carried out in an ultra-dry room with a dew point <-30°C: the prepared composite material slurry is coated on the copper foil with a thickness of 300 microns; after coating, it is transferr...

Embodiment 2

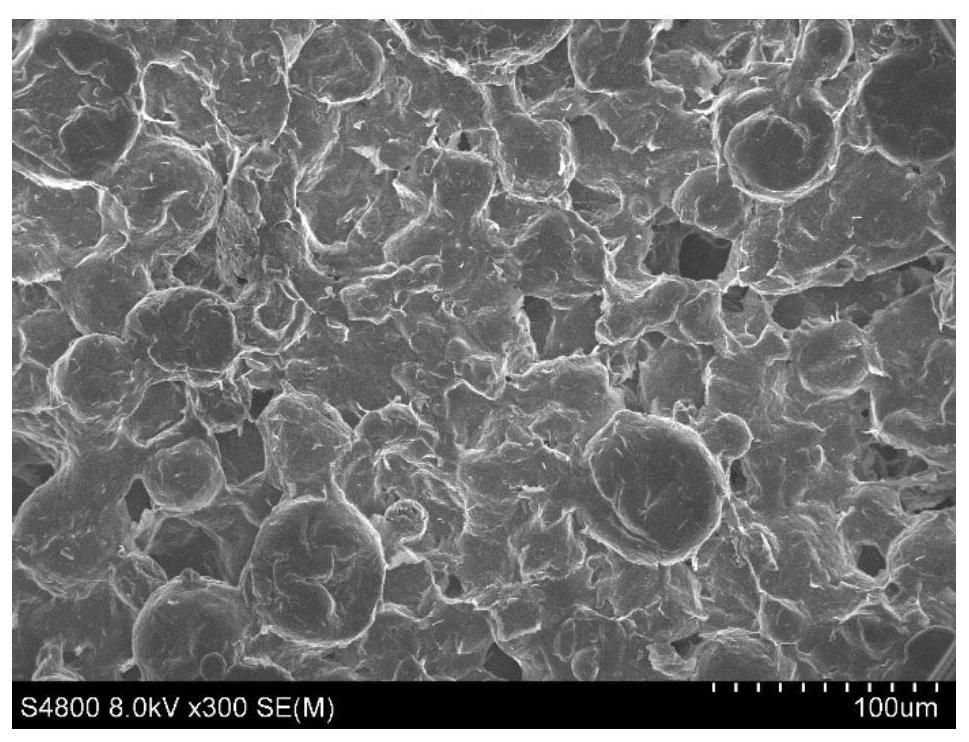

[0144] The product was prepared according to the method of Example 1, the difference from Example 1 was that 5 wt% PVDF solution was used as the binder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com