Hollow flat plate ceramic membrane support body and preparation method thereof

A ceramic membrane support body and a technology for a support body, which are applied in the field of ceramic membranes, can solve the problems of small filtration flux, decreased support body strength, low drying efficiency, etc., and achieve simple and efficient process methods, reduce deformation and cracking, and reduce raw material costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of the hollow flat ceramic membrane support body described in this embodiment comprises the following steps:

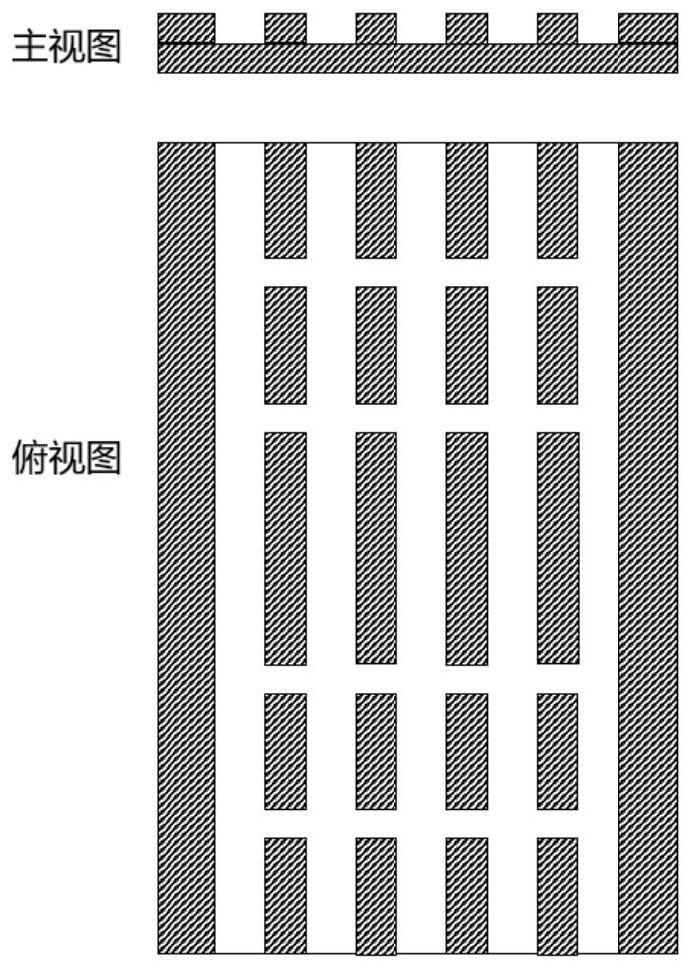

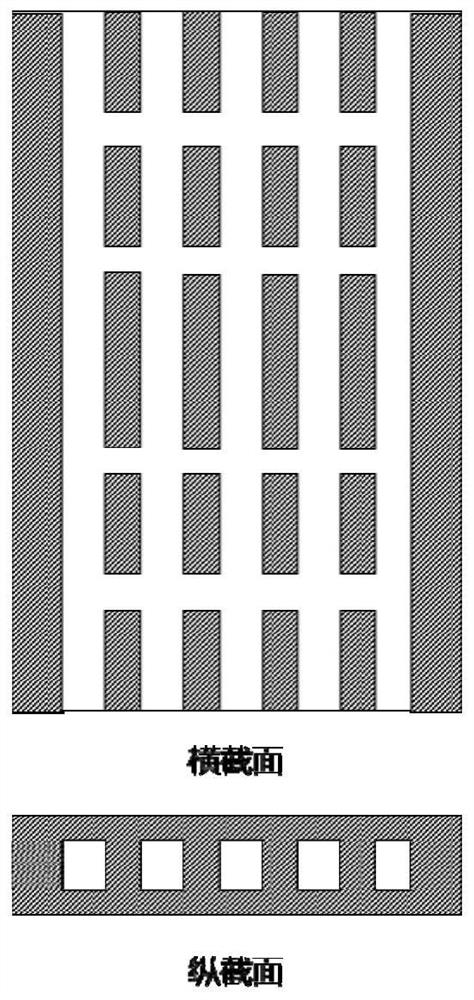

[0042] (1) Use 30wt% alumina, 20wt% zirconia, 20wt% kaolin, 20wt% mullite, and 10wt% albite as the support aggregate, and add 5wt% sawdust and 10wt% sawdust to the aggregate. % starch and 30wt% carboxymethyl cellulose solution (concentration 1wt%) are mixed, after drying, crushing, sieving, granulating, after being dried to moisture content 5%-8%, be pressed into size under 50MPa pressure A 1200*600*2mm flat ceramic membrane support body with strip-shaped protrusions on the surface and a flat ceramic membrane support body with a size of 1200*600*2mm, the protrusions are evenly distributed on the flat surface The upper surface of the ceramic membrane support body is consistent with the length direction of the support body, and is arranged side by side at intervals in the length direction and width direction of the support body; the length of...

Embodiment 2

[0048] The preparation method of the hollow flat ceramic membrane support body described in this embodiment comprises the following steps:

[0049] (1) 5wt% aluminum oxide, 95wt% kaolin are support body aggregates, add bamboo powder, 10wt% graphite and 16wt% lignocellulose solution (concentration 5wt%) for aggregate consumption 10wt% in the aggregate, mix, After drying, crushing, sieving, and granulation, after drying to a moisture content of 5%-8%, press it under a pressure of 50MPa to form a flat ceramic membrane support with a size of 1200*600*2mm and strip-shaped protrusions on the surface. Body green body and a flat ceramic membrane support body with a size of 1200*600*2mm, the protrusions are evenly distributed on the upper surface of the flat ceramic membrane support body, consistent with the length direction of the support body , and in the length direction and width direction of the support body, they are arranged side by side at intervals; the length of the protrusio...

Embodiment 3

[0054] The preparation method of the hollow flat ceramic membrane support body described in this embodiment comprises the following steps:

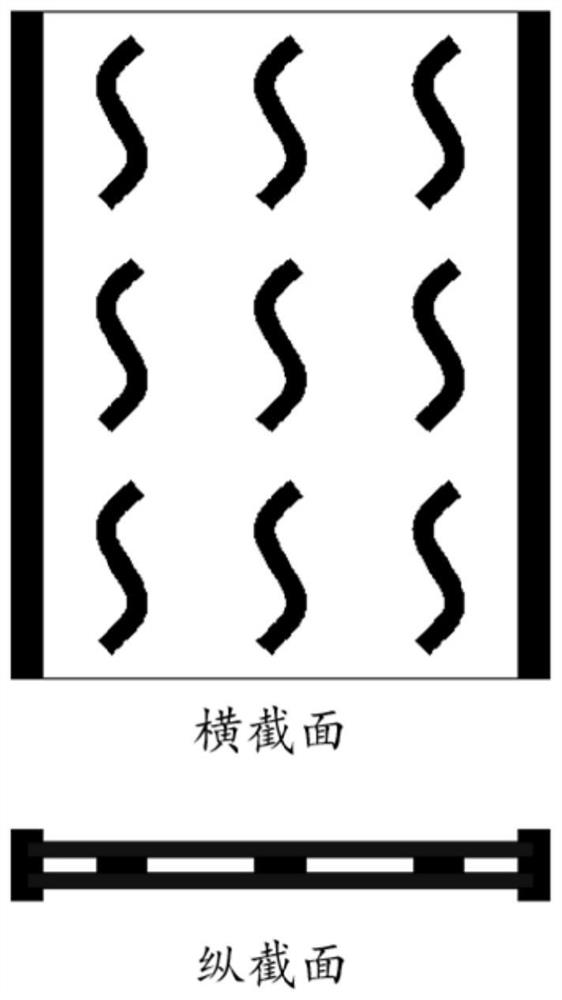

[0055] (1) 80wt% titanium dioxide, 15% bentonite, and 5wt% microsilica are used as the support body aggregate, and carbon black and 16wt% lignocellulose solution (concentration 5wt%) are mixed in the aggregate , after drying, crushing, sieving and granulation, after drying to a moisture content of 5%-8%, press under a pressure of 50MPa to form a flat ceramic membrane with a size of 1200*600*2mm and S-shaped protrusions on the surface The support body and the flat ceramic membrane support body with a size of 1200*600*2mm, the protrusions are evenly distributed on the upper surface of the flat ceramic membrane support body, consistent with the length direction of the support body, And in the length direction and width direction of the support body, they are arranged side by side at intervals; the length of the protrusions is 30-200mm, the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap