Magnetic photonic crystal microsphere for enriching and separating aflatoxin B1 as well as preparation method and application of magnetic photonic crystal microsphere

A technology of magnetic photonic crystals and photonic crystal microspheres, which is applied in the field of separation science, can solve the problems of one-time use, extensive promotion and use restrictions, large consumption of organic reagents, cumbersome operation process, etc., to achieve selective enrichment and separation, overcome Reduced adsorption efficiency, simple and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

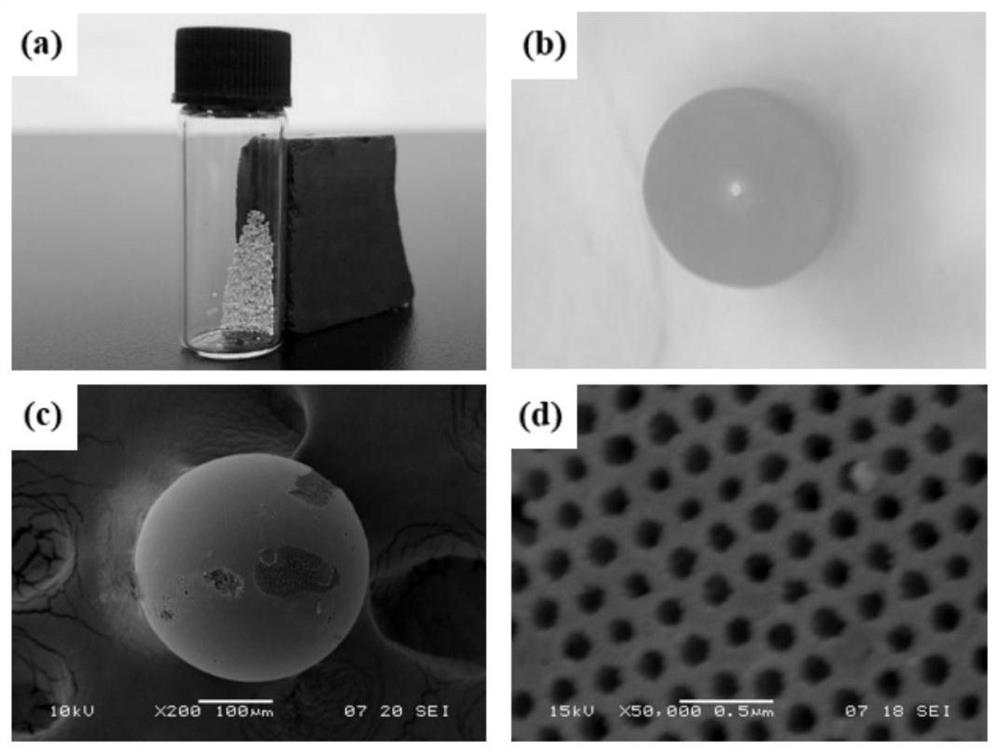

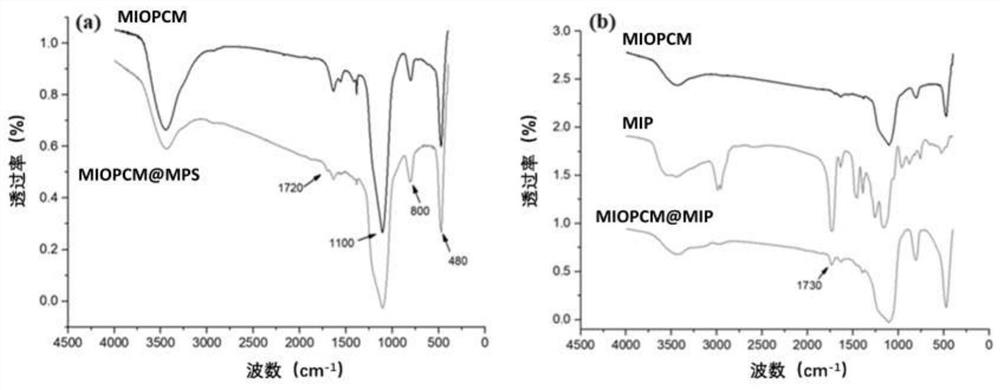

[0043] 1. Preparation of magnetic inverse opal photonic crystal microspheres:

[0044] Take 20% SiO 2 solution, 10% PS solution and 2.5% Fe 3 o 4 The solution was placed in a centrifuge tube, ultrasonically mixed into a homogeneous emulsion, transferred to a 5mL syringe, and another large 50mL syringe was filled with methicone. The two syringes were respectively fixed on the constant flow micro-flow pump, the microfluidic flow rate of the oil phase was 10mL / h, and the flow rate of the emulsion phase was 5mL / h. Using the principle of water-in-oil, methyl silicone oil cuts off the emulsion into micron-sized droplets and collects them in a plastic petri dish filled with methyl silicone oil (according to the literature: Journal of Chromatography A, 2020, 1626, 461379) . Afterwards, put the petri dish into a 60°C blast drying oven to dry at a constant temperature. After drying the water in the droplets, wash them with n-hexane and absolute ethanol for 3 to 4 times, and transfer...

Embodiment 2

[0049] The preparation method of Example 2 is the same as that of Example 1, except that acetic acid is used to adjust the pH to 6 when modifying the surface of the microspheres.

Embodiment 3

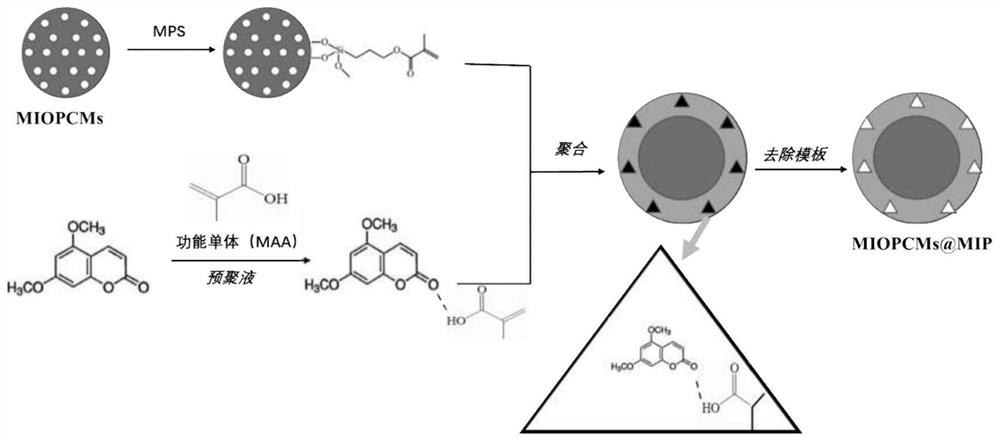

[0051] Using the surface-modified magnetic inverse opal photonic crystal microspheres prepared in Example 1 as the substrate, the molecularly imprinted magnetic microspheres were synthesized. The specific steps are as follows:

[0052] 1. Molecularly imprinted polymerization:

[0053] Using surface molecular imprinting technology, 10 mg of surface-modified microspheres were placed in a centrifuge tube, and template molecules, functional monomers, and cross-linking agents were added, and the volume was adjusted to 2 mL with a porogen (ie, the reaction solvent acetonitrile), and shaken at room temperature. The bed reacted for 15 minutes, and the rotation speed was 180 rpm. Then fill with nitrogen for 3 minutes, then add the initiator, seal the centrifuge tube with a parafilm, and finally put it into a shaker at 60° C. and 180 rpm for 24 hours. After the reaction is over, the reaction liquid is discarded under the action of a magnet to obtain microspheres coated with an organic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com