Method for measuring content of sulfur in steel rolling oily sludge

A technology of sulfur content and oil sludge, which is applied in the field of chemical analysis, can solve the problems of gas circuit blockage, large human operation errors, cumbersome steps, etc., and achieve the effects of reducing consumption, shortening service life, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

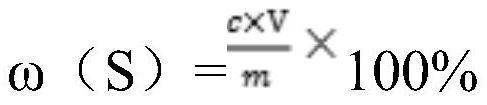

[0040] A method for measuring the sulfur content in steel rolling oily sludge, the specific implementation steps of the measuring method are as follows:

[0041] (1) Drying and grinding: Retrieve steel rolling oily sludge sample 1# on site, place it in a drying oven, dry at 110°C for 2 hours, and pass the sample through a 120-mesh metal mesh screen after drying and grinding;

[0042] (2) Burning at low temperature: take the sample obtained in step (1), put it in a muffle furnace and burn it at 450°C for 1.5h;

[0043] (3) Digestion: Weigh 0.1000 g of the sample obtained in step (2), add 20 mL, 50% dilute nitric acid, and 3 mL perchloric acid, and carry out digestion treatment on a 180° C. When the volume of the digestion solution is 0.5-1mL, remove it;

[0044] (4) Acidification: dissolve the digestion solution with 5mL of water, add 10mL of dilute hydrochloric acid to acidify, and dilute to a 100mL volumetric flask to obtain the solution to be tested, and make a reagent blan...

Embodiment 2

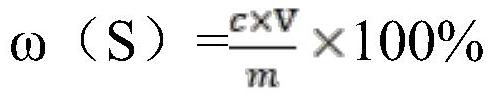

[0057] A method for measuring the sulfur content in steel rolling oily sludge, the specific steps of the method for the determination are as follows:

[0058] (1) Drying and grinding: Retrieve steel rolling oily sludge sample 2# in the drying oven, dry at 105°C for 3 hours, and pass the sample through a 120-mesh metal mesh screen after drying and grinding;

[0059] (2) Burning at low temperature: take the sample obtained in step (1), put it in a muffle furnace and burn it at 500°C for 1.5h;

[0060] (3) Digestion: Weigh 0.2000 g of the sample obtained in step (2), add 30 mL, 50% dilute nitric acid, and 5 mL perchloric acid, carry out digestion treatment on a 200° C. When the volume of the digestion solution is 0.5-1mL, remove it;

[0061] (4) Acidification: Dissolve the digestion solution with 3mL of water, add 10mL of dilute hydrochloric acid to acidify, and dilute to a 100mL volumetric flask to obtain the solution to be tested, and make a reagent blank along with the sample...

Embodiment 3

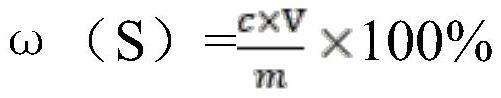

[0068] A method for measuring the sulfur content in steel rolling oily sludge, the specific steps of the method for the determination are as follows:

[0069] (1) Drying and grinding: Retrieve steel rolling oily sludge sample 3# on site and place it in a drying oven, dry at 110°C for 2.5 hours, and pass the sample through a 120-mesh metal mesh screen after drying and grinding;

[0070] (2) Burning at low temperature: take the sample obtained in step (1), put it in a high-temperature furnace and burn at 480°C for 2 hours;

[0071] (3) Digestion: Weigh 0.1500 g of the sample obtained in step (2), add 30 mL, 50% dilute nitric acid, and 4 mL perchloric acid, carry out digestion treatment on a 160° C. When the volume of the digestion solution is 0.5-1mL, remove it;

[0072] (4) Acidification: dissolve the digestion solution with 5mL of water, add 10mL of dilute hydrochloric acid to acidify, and dilute to a 100mL volumetric flask to obtain the solution to be tested, and make a reag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com