Shape-controllable high-performance lithium ion battery negative electrode material and preparation method thereof

A technology of lithium ion battery and negative electrode material, applied in battery electrodes, active material electrodes, negative electrodes, etc., can solve the problems of stability impact of lithium ion battery charging and discharging process, loss of electrical contact of active components, etc., to speed up charging and discharging rate, promotes efficient penetration, and shortens the diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

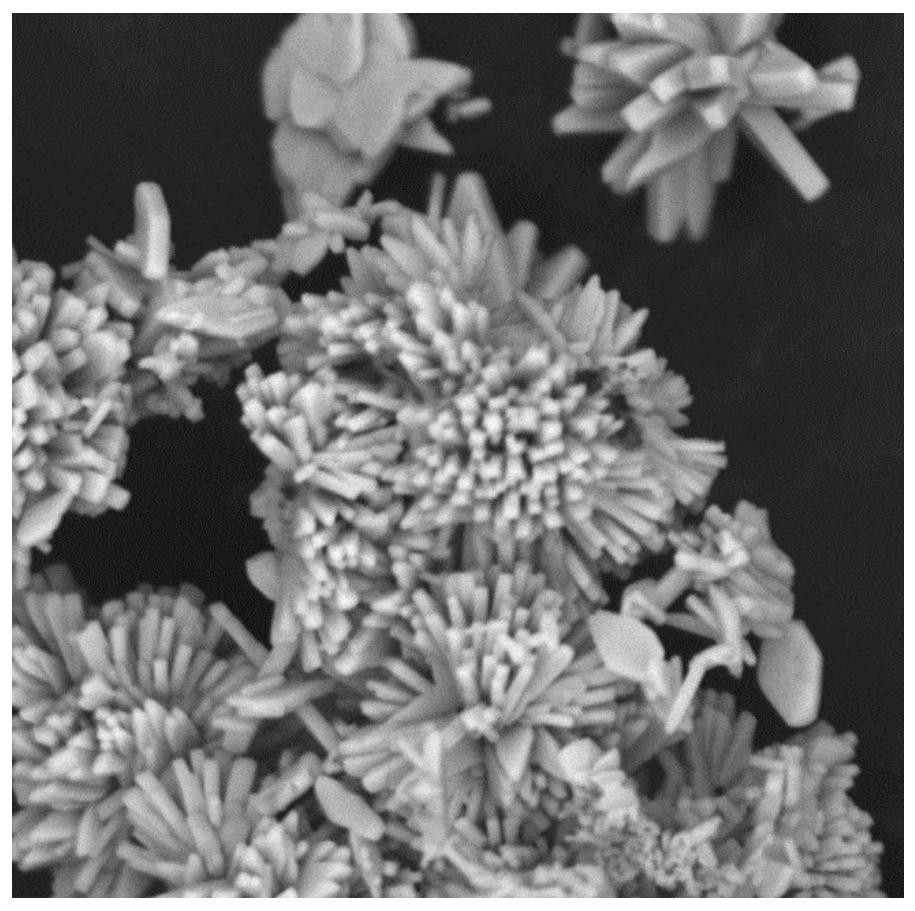

Image

Examples

Embodiment 1

[0034] The preparation method of the lithium ion battery negative electrode material of the present embodiment comprises the following steps:

[0035] Step 1: Add 1.3g of copper nitrate trihydrate and 0.8g of urea to 280mL of distilled water under low-speed stirring, dissolve 0.13g of PVP in 6.5mL of distilled water, and mix the two solutions.

[0036] Step 2: The above mixed solution is fully stirred by a magnetic stirrer for 60 minutes to fully dissolve it, and then the above solution is transferred to a polytetrafluoroethylene hydrothermal synthesis kettle, and after screwing and closing, the temperature is kept in an electric oven. Reaction at ℃ for 16h.

[0037] Step 3: After reaching the reaction time, the hydrothermal synthesis kettle is naturally cooled to room temperature together with the electric oven. After the reaction, the solid-liquid mixture was repeatedly centrifuged at 7000 rpm for 20 minutes, and washed repeatedly with distilled water and ethanol to obtain ...

Embodiment 2

[0041] The preparation method of the lithium ion battery negative electrode material of the present embodiment comprises the following steps:

[0042] Step 1: Add 1.2 g of copper nitrate trihydrate and 0.6 g of urea to 280 mL of distilled water under low-speed stirring, dissolve 0.12 g of PVP in 6 mL of distilled water, and mix the two solutions.

[0043] Step 2: The above mixed solution is fully stirred by a magnetic stirrer for 60 minutes to fully dissolve it, and then the above solution is transferred to a polytetrafluoroethylene hydrothermal synthesis kettle, and the temperature is kept in an electric heating oven after screwing it tightly closed. Reaction at ℃ for 14h.

[0044] Step 3: After reaching the reaction time, the hydrothermal synthesis kettle is naturally cooled to room temperature together with the electric oven. After the reaction, the solid-liquid mixture was repeatedly centrifuged at 7000 rpm for 30 minutes, and washed repeatedly with distilled water and et...

Embodiment 3

[0050] The preparation method of the lithium ion battery negative electrode material of the present embodiment comprises the following steps:

[0051] Step 1: Add 1.4g of copper nitrate trihydrate and 0.9g of urea to 300mL of distilled water under low-speed stirring, dissolve 0.14g of PVP in 7mL of distilled water, and mix the two solutions.

[0052] Step 2: The above mixed solution is fully stirred by a magnetic stirrer for 90 minutes to fully dissolve it, and then the above solution is transferred to a polytetrafluoroethylene hydrothermal synthesis kettle, and the temperature is kept in an electric heating oven after screwing it tightly closed. Reaction at ℃ for 14h.

[0053] Step 3: After reaching the reaction time, the hydrothermal synthesis kettle is naturally cooled to room temperature together with the electric oven. After the reaction, the solid-liquid mixture was repeatedly centrifuged at 6000 rpm for 30 minutes, and washed repeatedly with distilled water and ethanol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com