Polymer material with shape and color memory function as well as preparation method and application of polymer material

A polymer material and color technology, applied in the field of shape memory polymer materials, can solve the problems of application limitation, single function reversible deformation, no other functions, etc., and achieve the effects of low production cost, good mechanical properties, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of polymer material with shape and color memory function, its preparation method comprises the following steps:

[0037] 1) Mix 3 g of caprolactone and 0.2 g of pentaerythritol, react at 130° C. for 12 h under a nitrogen atmosphere, then add 2 mL of chloroform to the reaction product, and then add the obtained solution dropwise into 200 mL of methanol for precipitation. Collect the precipitate, dry it in vacuum at 30°C to constant weight, and obtain the prepolymer P1;

[0038] 2) 0.4g of prepolymer P1, 49.4mg of compound M3 (refer to RSC Adv., 2015, 5, 77922-77931 for the synthesis method; Sci.China Chem., 2016, 59, 1554-1560), 6mg of (Refer to J.Mater.Chem.C 2013,1,4640 for the synthesis method) and 2.5mg of DABCO were dispersed in 2mL of tetrahydrofuran, stirred at 25°C for 60s, then poured into a polytetrafluoroethylene mold, and transferred to a fume hood The solvent was left to evaporate completely and naturally for 2 days, and the polymer material PC1 wit...

Embodiment 2

[0053] A kind of polymer material with shape and color memory function, its preparation method comprises the following steps:

[0054] 1) Mix 3g of lactide and 84mg of pentaerythritol, react at 120°C for 24h under a nitrogen atmosphere, then add 2mL of chloroform to the reaction product, and then add the obtained solution dropwise into 200mL of methanol for precipitation and collection The precipitate was vacuum-dried at room temperature to constant weight to obtain prepolymer P2;

[0055] 2) 0.4g of prepolymer P2, 35.6mg of M3 (synthetic method refer to RSC Adv., 2015, 5, 77922-77931; Sci.China Chem., 2016, 59, 1554-1560), 6mg of (Refer to J.Mater.Chem.C 2013,1,4640 for the synthesis method) and 2.5mg of DABCO were dispersed in 2mL of tetrahydrofuran, stirred at 25°C for 60s, then poured into a polytetrafluoroethylene mold, and transferred to a fume hood Leave it for 2 days for the solvent to evaporate completely and naturally to obtain the polymer material PC2 with shape a...

Embodiment 3

[0063] A kind of polymer material with shape and color memory function, its preparation method comprises the following steps:

[0064] 0.4g of four-arm polyethylene glycol P3, 17.8mg of M3 (refer to RSC Adv., 2015, 5, 77922-77931 for the synthesis method; Sci.China Chem., 2016, 59, 1554-1560), 6mg of (Refer to J.Mater.Chem.C 2013,1,4640 for the synthesis method) and 2.5mg of DABCO were dispersed in 2mL of tetrahydrofuran, stirred at 25°C for 60s, then poured into a polytetrafluoroethylene mold, and transferred to a fume hood Leave it for 2 days for the solvent to evaporate completely and naturally to obtain the polymer material PC3 with shape and color memory functions.

[0065] The preparation reaction of the polymer material PC3 with shape and color memory function of the present embodiment is as follows:

[0066]

[0067] Performance Testing:

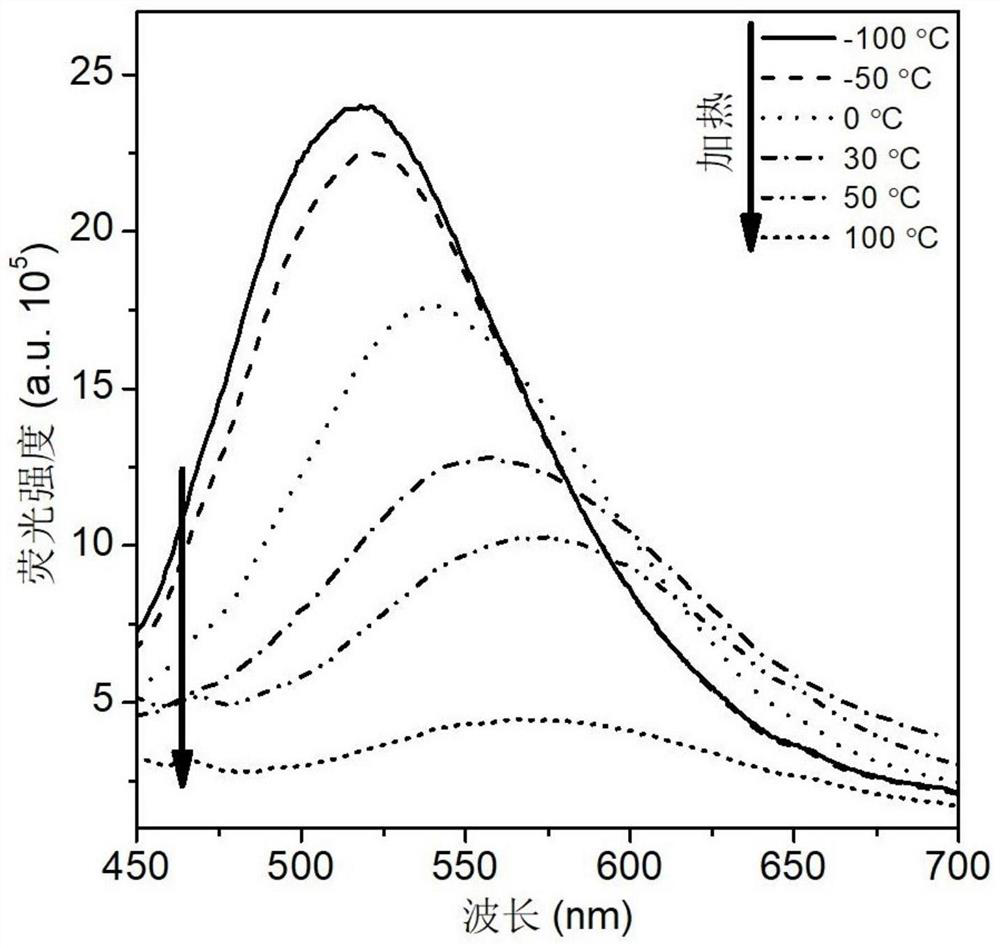

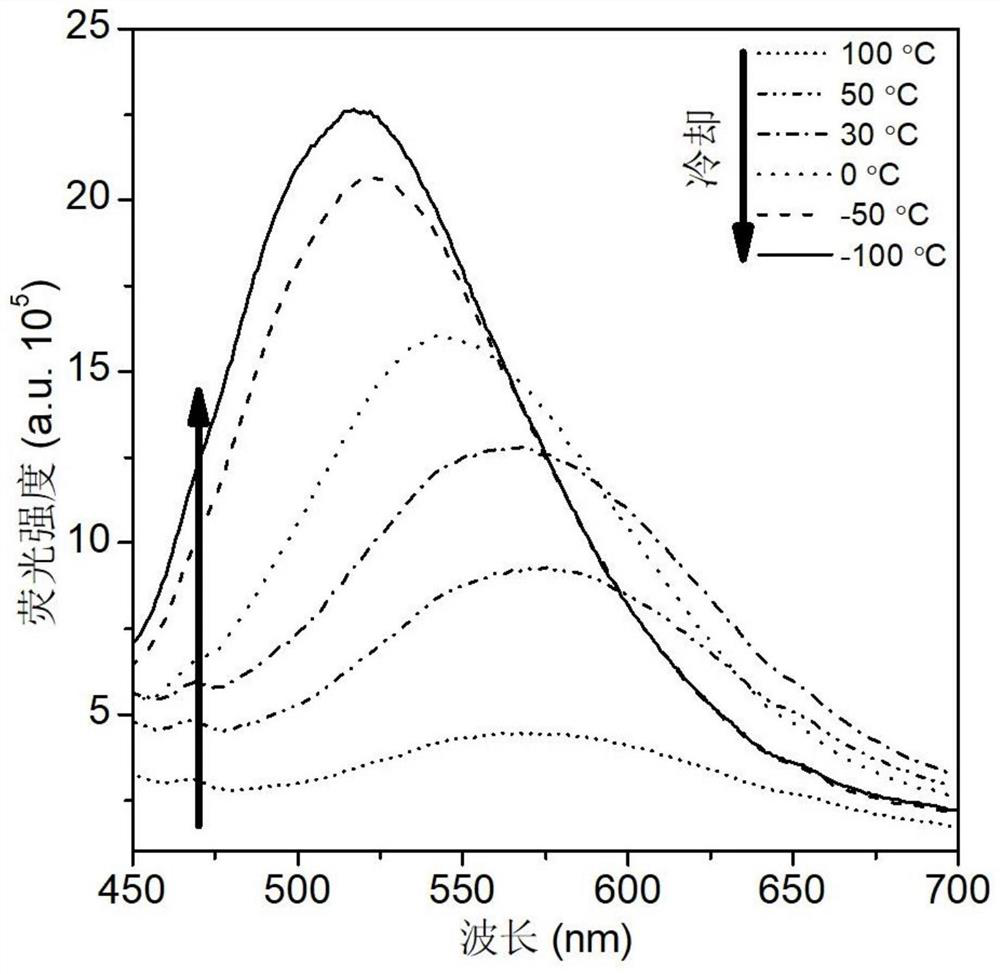

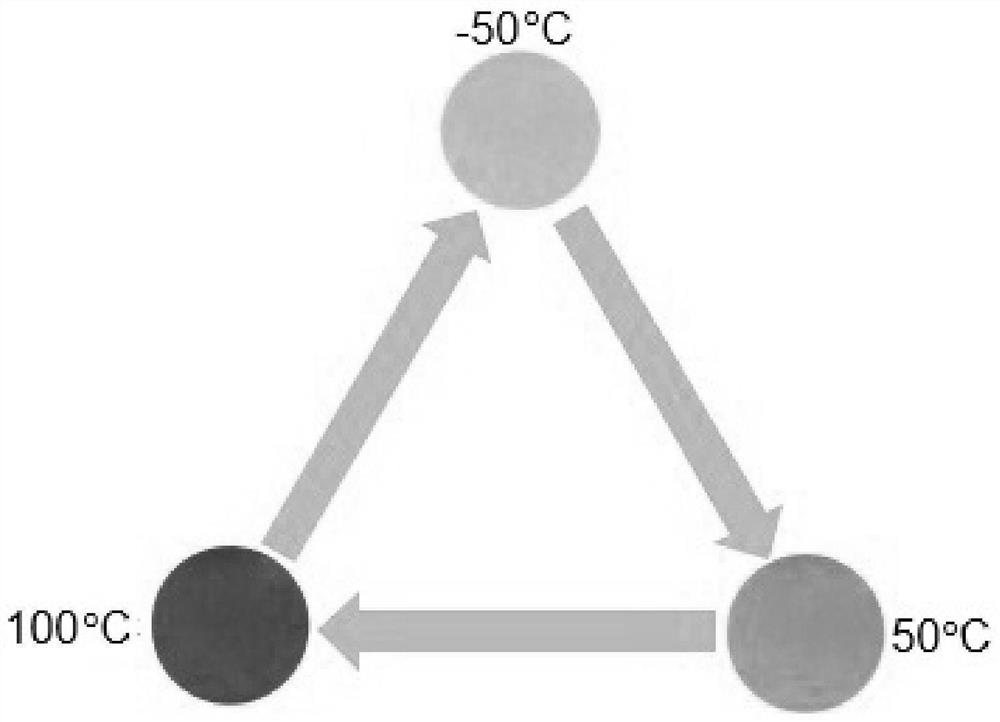

[0068] The fluorescence spectrum in the film temperature rising process (from -100°C to 40°C) prepared from the polymer mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com