Acidification blocking remover and preparation method thereof

A plugging agent, hydrochloric acid technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of high corrosion rate of steel, high acid strength, oil-water emulsification, etc., and achieves simple preparation process, high scale dissolution rate, The effect of low corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

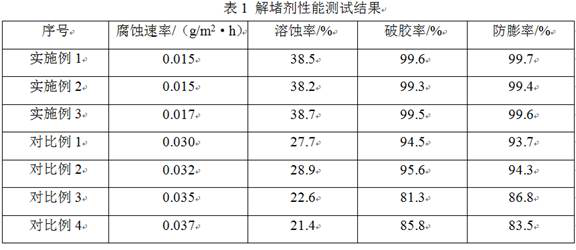

Examples

Embodiment 1

[0043] The acidifying plug-removing agent described in Example 1 includes a prepositioning liquid, a main body liquid and a postpositioning liquid; wherein, the main body liquid is composed of the following raw materials in parts by weight: 13 parts of hydrochloric acid, 20 parts of fluoboric acid 3.3 parts of acetic acid, 1.4 parts of ammonium fluoride, 0.8 parts of ammonium bifluoride, 1.7 parts of sodium nitrite, 2.0 parts of polyoxyethylene amine, 4 parts of corrosion inhibitor, 1.2 parts of iron ion stabilizer, 3.5 parts of penetrant, 1.5 parts of sodium amine di-o-phenylacetate, 1.5 parts of water.

[0044] in:

[0045] The iron ion stabilizer is hydroxyethylidene diphosphonic acid.

[0046] The corrosion inhibitor is a mixture of oleic acid imidazoline quaternary ammonium salt and sodium gluconate.

[0047] The penetrating agent is a mixture of 2-methyl-2,4-pentanediol, oleic acid diethanolamide and polyoxyethylene polyoxypropylene propylene glycol ether.

[0048] Th...

Embodiment 2

[0071] The acidifying plug-removing agent described in Example 2 includes a prepositioning liquid, a main body liquid and a postpositioning liquid; wherein, the main body liquid consists of the following raw materials in parts by weight: 15 parts of hydrochloric acid, 17 parts of fluoboric acid 2.5 parts of acetic acid, 1.2 parts of ammonium fluoride, 0.9 parts of ammonium bifluoride, 1.5 parts of sodium nitrite, 1.7 parts of polyoxyethylene amine, 3 parts of corrosion inhibitor, 1 part of iron ion stabilizer, 4 parts of penetrant, 1.2 parts of sodium di-o-phenylacetate, 1 part of water.

[0072] in:

[0073] The iron ion stabilizer is hydroxyethylidene diphosphonic acid.

[0074] The corrosion inhibitor is a mixture of oleic acid imidazoline quaternary ammonium salt and sodium gluconate.

[0075] The penetrating agent is a mixture of 2-methyl-2,4-pentanediol, oleic acid diethanolamide and polyoxyethylene polyoxypropylene propylene glycol ether.

[0076] The polyoxyethylene...

Embodiment 3

[0092] The acidifying plug-removing agent described in Example 3 includes a prepositioning liquid, a main body liquid and a postpositioning liquid; wherein, the main body liquid is composed of the following raw materials in parts by weight: 12 parts of hydrochloric acid, 18 parts of fluoboric acid 2.8 parts of acetic acid, 1.5 parts of ammonium fluoride, 1.0 parts of ammonium bifluoride, 1.8 parts of sodium nitrite, 1.5 parts of polyoxyethylene amine, 5 parts of corrosion inhibitor, 1.5 parts of iron ion stabilizer, 5 parts of penetrant, 1.4 parts of sodium di-o-phenylacetate and 2 parts of water.

[0093] in:

[0094] The iron ion stabilizer is hydroxyethylidene diphosphonic acid.

[0095] The corrosion inhibitor is a mixture of oleic acid imidazoline quaternary ammonium salt and sodium gluconate.

[0096] The penetrating agent is a mixture of 2-methyl-2,4-pentanediol, oleic acid diethanolamide and polyoxyethylene polyoxypropylene propylene glycol ether.

[0097] The polyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com