Biological shearing agent for improving shale oil layer oil extraction efficiency and preparation method and application thereof

A biological and oil layer technology, applied in the chemical field, can solve the problems of reduced surfactant activity, low permeability of rock formations, difficulty in coping with permeability, etc., and achieve the effect of good binding force and low viscosity of injection fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

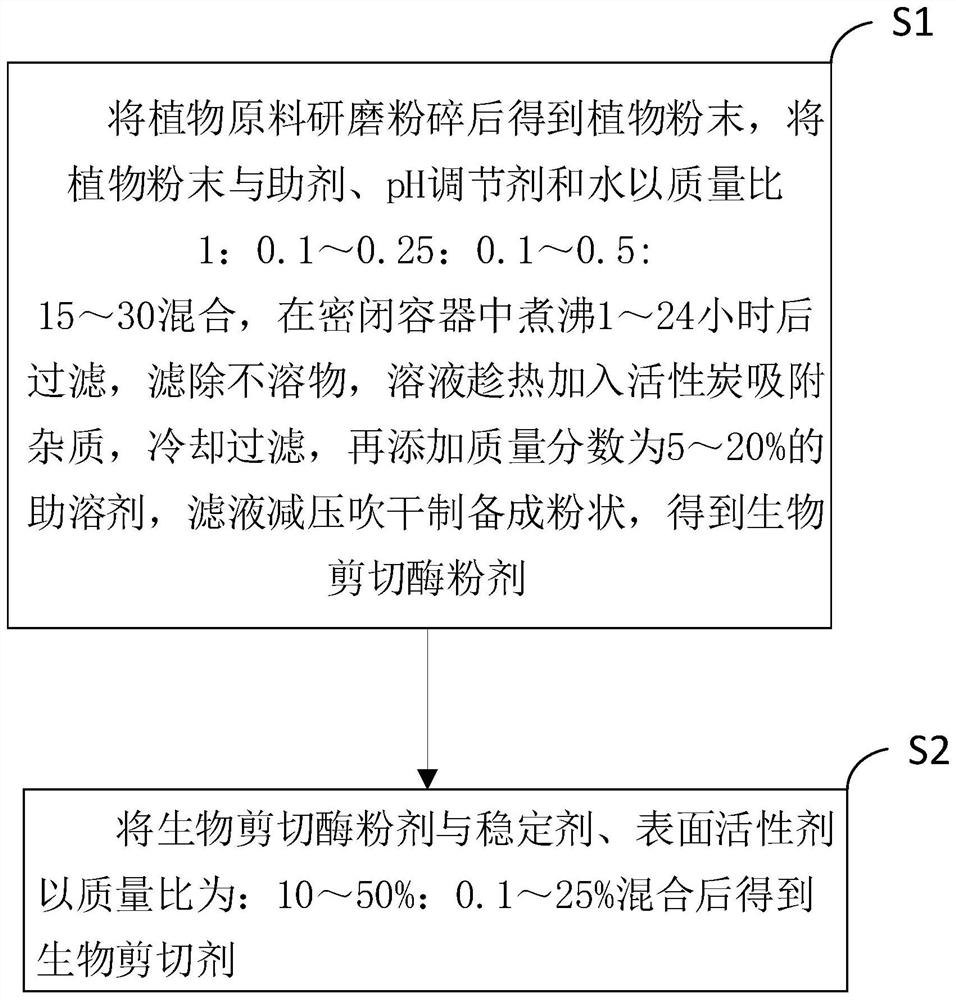

[0061] Such as figure 1 Shown, a kind of biological shearing agent preparation method that improves oil recovery efficiency of shale oil layer, comprises the following steps:

[0062] S1. Biological shearing enzyme extraction: Grind and pulverize plant raw materials to obtain plant powder, mix plant powder with additives, pH regulator and water at a mass ratio of 1:0.1~0.25:0.1~0.5:15~30, and place in a closed After boiling in the container for 1-24 hours, filter out the insoluble matter and absorb impurities, then add a co-solvent with a mass fraction of 5-20%, dissolve and dry to obtain a biological shearing enzyme powder;

[0063] Plant raw materials include one or more of the following and their products or extracts: golden buckwheat, catechin, persimmon stalk, grape seed, green tea, pomegranate peel and gallnut;

[0064] The auxiliary agent is sulfite;

[0065] S2. Preparation of bio-shearing agent: mix bio-shearing enzyme powder with stabilizer and surfactant in a mass...

Embodiment 2

[0069] Such as figure 1 Shown, a kind of biological shearing agent preparation method that improves oil recovery efficiency of shale oil layer, comprises the following steps:

[0070] S1. Biological shearing enzyme extraction: Grind and pulverize plant raw materials to obtain plant powder, mix plant powder with additives, pH regulator and water at a mass ratio of 1:0.1~0.25:0.1~0.5:15~30, and place in a closed After boiling in a container for 1-24 hours, filter to remove insoluble matter, add activated carbon to the solution while it is hot to absorb impurities, cool and filter, then add a co-solvent with a mass fraction of 5-20%, and dry the filtrate under reduced pressure to prepare a powder. Biological shearing enzyme powder;

[0071] Plant raw materials include one or more of the following and their products or extracts: golden buckwheat, catechin, persimmon stalk, grape seed, green tea, pomegranate peel, gall, emblica, lichen, salvia, banyan leaf, astragalus, and nightsh...

Embodiment 3

[0084] [1] Formation status: Formation temperature 95°C, rock type siltstone (quartz sand), porosity ~ 2%;

[0085] [2] Plant material: golden buckwheat flour + catechin powder (2:1);

[0086] [3] Processing method:

[0087] After the plant material is pulverized, add a pH regulator, sodium sulfide (10% added), ammonium chloride (5%), sodium sulfite (12%) and 2000% water;

[0088] Boil under pressure at 110°C for 20 hours, filter to remove insoluble matter, add activated carbon and continue to boil for 1 hour, then filter to obtain the solution;

[0089] Add co-solvent glucose to the solution, the addition amount is 15%;

[0090] Dry the solution under reduced pressure to make a dry powder, and mix it with sodium dithionite and disodium EDTA (5%, 12%) to obtain a biological shearing agent;

[0091] [4] How to use:

[0092] The biological shearing agent is dissolved in tap water according to 0.2% mass ratio, and 0.01% butanol is added at the same time, and injected into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com