Lithium battery and manufacturing method thereof

A lithium battery and lithium salt technology, applied in the field of lithium battery and its production, can solve the problems of shortening the battery cycle life, unable to protect the electrode, and the collapse of the positive electrode of the battery, so as to avoid uneven distribution of local current density, good cycle performance, transmission uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

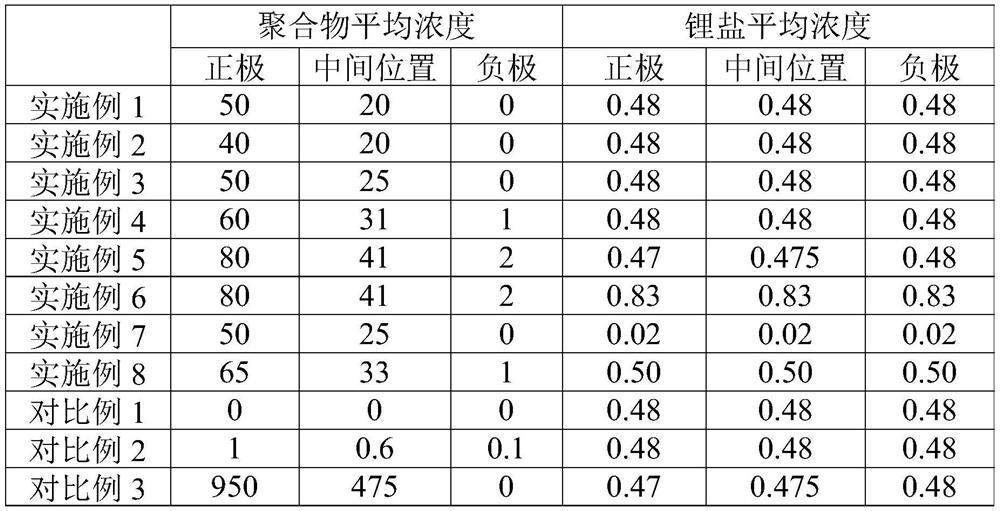

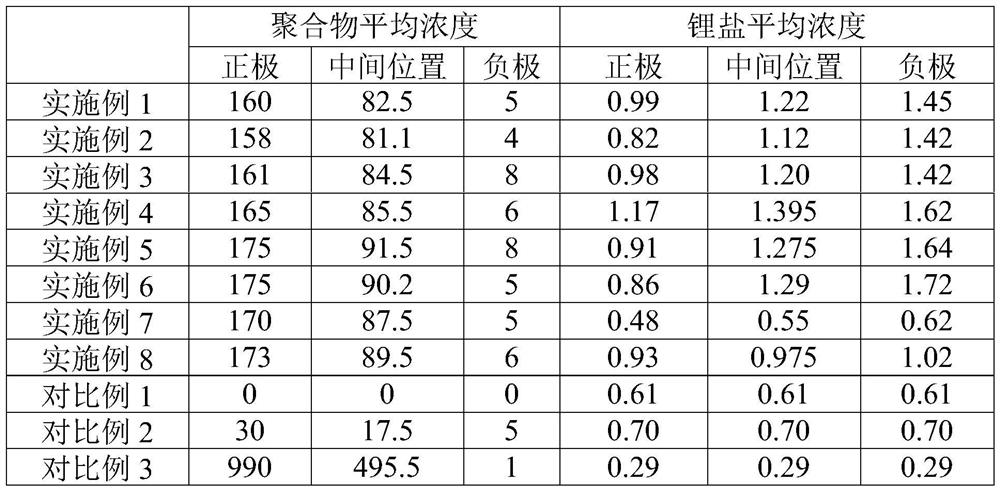

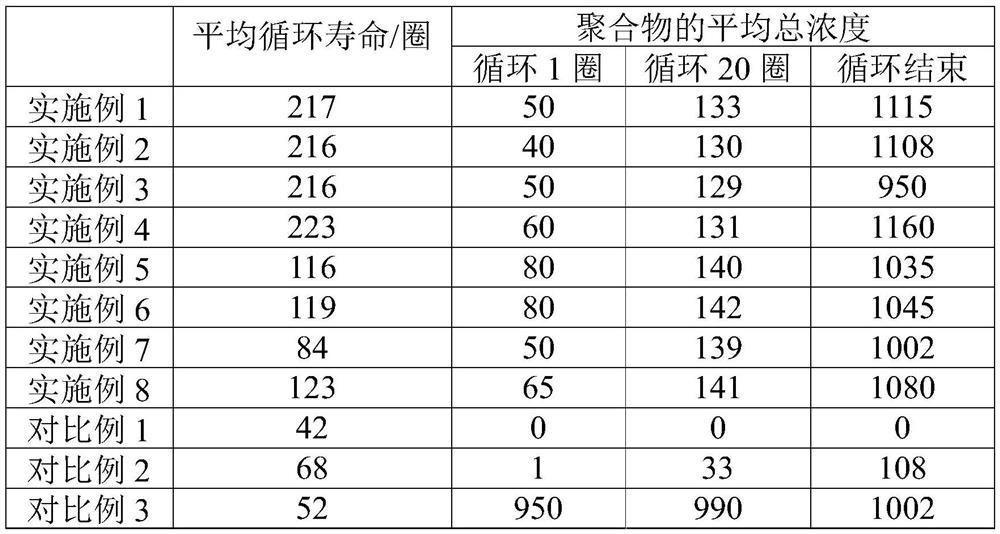

Embodiment 1

[0040] S1: Production of positive electrode sheet: 930g surface-treated modified positive electrode active material LiFePO 4 , 30g adhesive PVDF, 20g acetylene black, 20g conductive agent HV and 2g solid initiator azobisisobutyronitrile (AIBN) were added to 1500g solvent nitrogen methyl pyrrolidone NMP, and then stirred in a vacuum mixer to form a stable and uniform positive electrode slurry. The positive electrode slurry was uniformly and intermittently coated on both sides of the positive electrode current collector aluminum foil (aluminum foil size: width 160 mm, thickness 16 μm), then dried at 393 K, and the positive electrode sheet was obtained after being pressed by a roller press.

[0041] S2: Production of the negative electrode sheet: In the glove box, cut the metal lithium foil with a thickness of 50 μm on one side into a suitable size, and then cut the metal lithium foil into a size of 45mm (length) × 58mm (width) in a drying room The negative electrode in which th...

Embodiment 2

[0045] The lithium battery was prepared by the method of Example 1, except that the solid initiator in step S1 was benzoyl peroxide BPO / sucrose.

Embodiment 3

[0047] The lithium battery is prepared by the method of Example 1, the difference is only that in the preparation of the electrolyte in step S2, the vinylene carbonate organic solvent is replaced by an equal weight propylene carbonate organic solvent, and ethylene glycol diglycidyl The ether organic solvent was replaced by an equal weight of ethylene glycol dimethyl ether organic solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com