Ultraviolet curing adhesive with low surface viscosity and preparation method thereof

A technology of ultraviolet light and curing glue, applied in the direction of non-polymer organic compound adhesives, adhesives, adhesive additives, etc., can solve the problem of affecting the hardness, gloss and abrasion resistance of the coating film, high free radical activity, coating film Surface stickiness and other problems, to improve the use value, enhance the mechanical properties, improve the effect of surface stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Material ratio:

[0026] Based on the total mass of the system, matrix resin 40%; based on the total mass of matrix resin, polyolefin acrylate 1: 50%, polyolefin acrylate 2: 50%;

[0027] Based on the total mass of the system, the diluent is 53.3%; based on the total mass of the diluent, isobornyl acrylate: 80%, lauric acrylate: 20%;

[0028] In terms of the total mass of the system, the photoinitiator is 4.4%; in terms of the total mass of the photoinitiator, 2-methyl-1-(4-methylthiophenyl)-2-morpholine-1-acetone: 45%, 2 -Phenylbenzyl-2-dimethylamine-1-(4-morpholinebenzylphenyl) butanone: 55%;

[0029] Based on the total mass of the system, leveling agent: 0.3%, defoamer: 0.3%, coupling agent: 1.7%.

[0030] The above-mentioned materials are mixed and stirred at room temperature, and stirred evenly to obtain a UV-curable adhesive.

Embodiment 2

[0032] Material ratio:

[0033] Based on the total mass of the system, matrix resin 40%; based on the total mass of matrix resin, polyolefin acrylate 1: 50%, polyolefin acrylate 2: 50%;

[0034] Based on the total mass of the system, diluent 50.8%; based on the total mass of diluent, isobornyl acrylate: 80%, lauric acrylate: 20%;

[0035] In terms of the total mass of the system, the photoinitiator is 4.4%; in terms of the total mass of the photoinitiator, 2-methyl-1-(4-methylthiophenyl)-2-morpholine-1-acetone: 45%, 2 -Phenylbenzyl-2-dimethylamine-1-(4-morpholinebenzylphenyl) butanone: 55%;

[0036] Based on the total mass of the system, active ammonia crosslinking agent: 2.5%, leveling agent: 0.3%, defoamer: 0.3%, coupling agent: 1.7%.

[0037] The above-mentioned materials are mixed and stirred at room temperature, and stirred evenly to obtain a UV-curable adhesive.

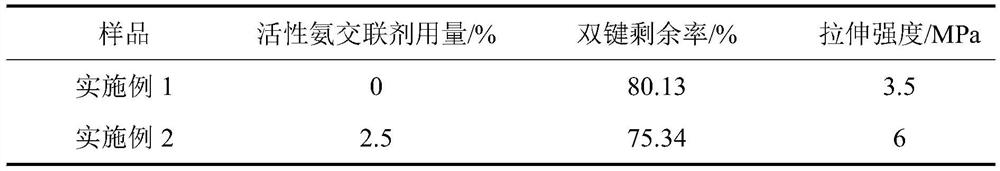

[0038] At room temperature, spread the UV glue prepared in Example 1 and Example 2 on a clean, smooth, fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com