Nanocellulose layer-by-layer self-assembled membrane and preparation method thereof

A nanocellulose, layer-by-layer self-assembly technology, applied in the field of membrane separation, can solve the problems of easy contamination, insufficient rigidity of nanofiltration membrane, low permeation flux and stability, etc., and achieve simple and efficient preparation process and adjustable separation pore size control, excellent permeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

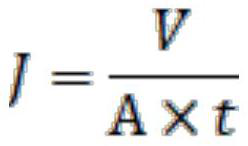

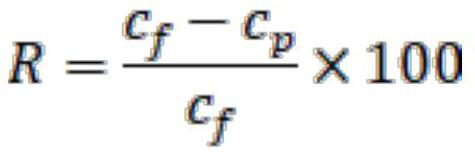

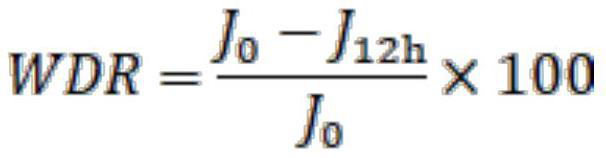

Image

Examples

Embodiment 1

[0027] S1. Prepare a 5cm×5cm hydrolyzed polyacrylonitrile ultrafiltration base membrane;

[0028] S2. Soak the polyacrylonitrile ultrafiltration membrane in 100 mL of quaternary ammonium cellulose nanofiber (charge amount 1.0 mmol / g) aqueous solution with a concentration of 0.01% and a pH of 7.0 for 10 minutes, take out the membrane and rinse it with deionized water to remove Unbound quaternary ammonium cellulose nanofibers on the membrane surface;

[0029] S3, then immerse the membrane in 100 mL of TEMPO-cellulose nanofiber (charge amount 1.0 mmol / g) aqueous solution with a concentration of 0.01% and a pH of 7.0 for 10 min, and complete the assembly process of the first double layer under the drive of electrostatic force , the membrane is taken out and rinsed with deionized water to remove unbound TEMPO-cellulose nanofibers on the membrane surface;

[0030] S4. Repeat steps S2-S3 once to obtain a nanocellulose self-assembled separation membrane layer by layer.

Embodiment 2

[0032] S1. Prepare a 5cm×5cm hydrolyzed polyacrylonitrile ultrafiltration base membrane;

[0033] S2. Soak the polyacrylonitrile ultrafiltration membrane in 100 mL of quaternary ammonium cellulose nanofiber (charge amount 1.0 mmol / g) aqueous solution with a concentration of 0.01% and a pH of 7.0 for 10 minutes, take out the membrane and rinse it with deionized water to remove Unbound quaternary ammonium cellulose nanofibers on the membrane surface;

[0034] S3, then immerse the membrane in 100 mL of TEMPO-cellulose nanofiber (charge amount 1.0 mmol / g) aqueous solution with a concentration of 0.01% and a pH of 7.0 for 10 min, and complete the assembly process of the first double layer under the drive of electrostatic force , the membrane is taken out and rinsed with deionized water to remove unbound TEMPO-cellulose nanofibers on the membrane surface;

[0035] S4. Repeat steps S2-S3 twice to obtain a nanocellulose self-assembled separation membrane layer by layer.

Embodiment 3

[0037] S1. Prepare a 5cm×5cm hydrolyzed polyacrylonitrile ultrafiltration base membrane;

[0038] S2. Soak the polyacrylonitrile ultrafiltration membrane in 100 mL of quaternary ammonium cellulose nanofiber (charge amount 1.0 mmol / g) aqueous solution with a concentration of 0.01% and a pH of 7.0 for 10 minutes, take out the membrane and rinse it with deionized water to remove Unbound quaternary ammonium cellulose nanofibers on the membrane surface;

[0039] S3, then immerse the membrane in 100 mL of TEMPO-cellulose nanofiber (charge amount 1.0 mmol / g) aqueous solution with a concentration of 0.01% and a pH of 7.0 for 10 min, and complete the assembly process of the first double layer under the drive of electrostatic force , the membrane is taken out and rinsed with deionized water to remove unbound TEMPO-cellulose nanofibers on the membrane surface;

[0040] S4. Steps S2-S3 were repeated three times to obtain a nanocellulose self-assembled separation membrane layer by layer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Water permeation flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com