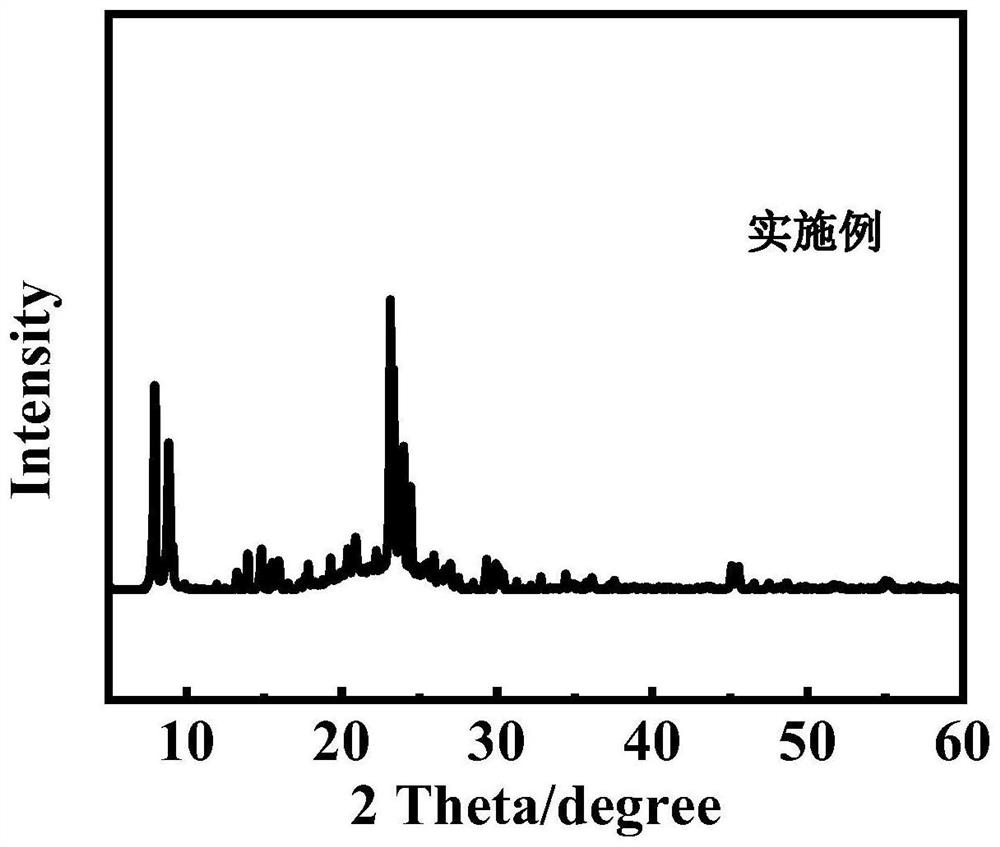

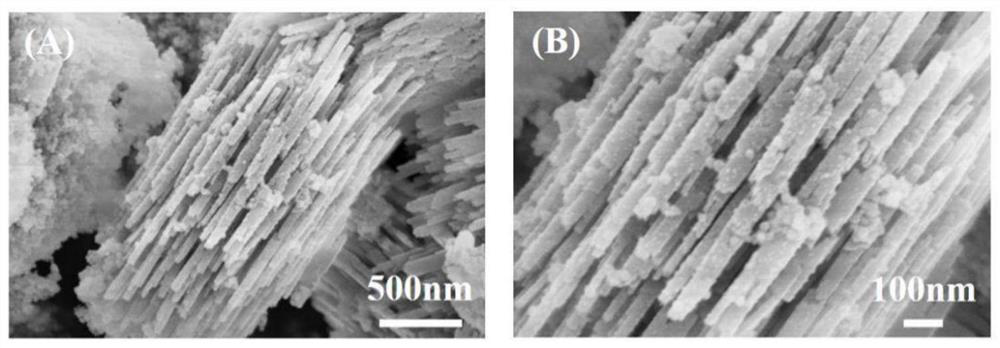

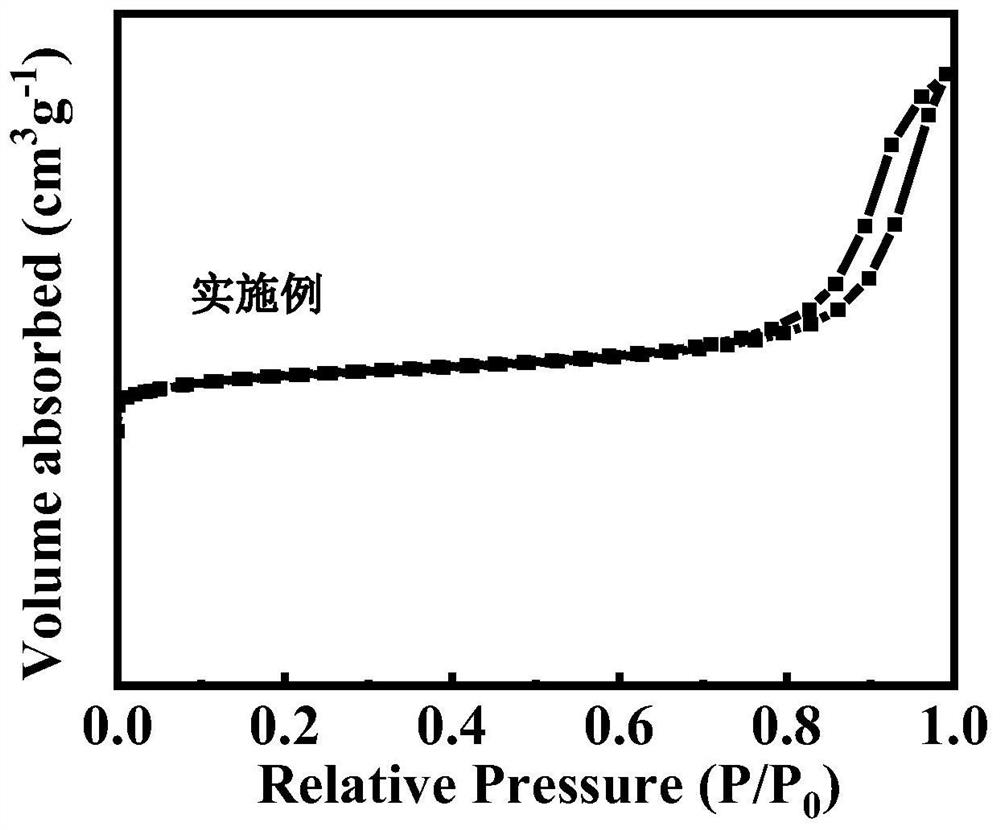

Pd-based hierarchical pore mesoporous-microporous TS-1 molecular sieve single crystal catalyst and preparation method thereof

A TS-1, molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of reducing the activity of TS-1 molecular sieves and low catalytic efficiency, and achieve small size and uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Provide a palladium-based grade hole mesoporous-microporous TS-1 molecular sieve single crystal catalyst, its preparation method comprises the following steps:

[0041] 1) 2g mesoporous pore forming agent polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123), 0.1g microporous pore forming agent sodium dodecylsulfonate (SDS ), 200mL of deionized water was added to the reaction vessel, stirred until clear, then 3.15g of silica gel solution (containing 1.26g of silicon dioxide) was added for ultrasonication for 30min, and then 1.2g of tris (Tris) was added to continue stirring, and finally Add the light yellow solution obtained by ultrasonically mixing 2 g of dopamine hydrochloride and deionized water into the above mixture, and stir overnight for 24 hours to obtain dark black solution I;

[0042] 2) Centrifuge the dark black solution I obtained in step 1) at a centrifugation rate of 9000r / 15min, and then place the obtained solid in an oven at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com