Self-adaptive intelligent material based on coordinate bond as well as preparation method and application of self-adaptive intelligent material

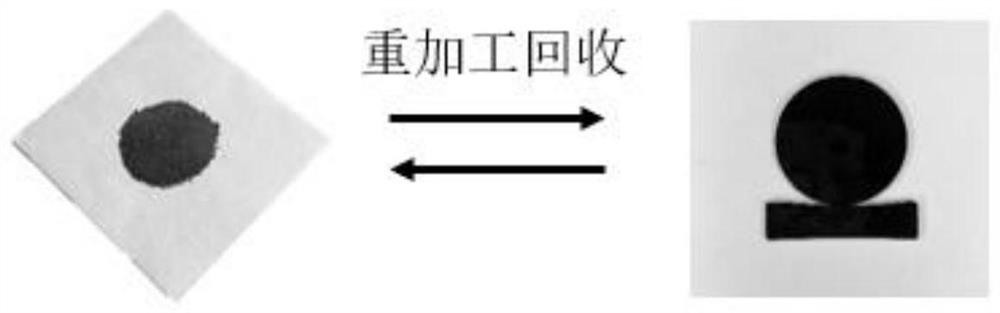

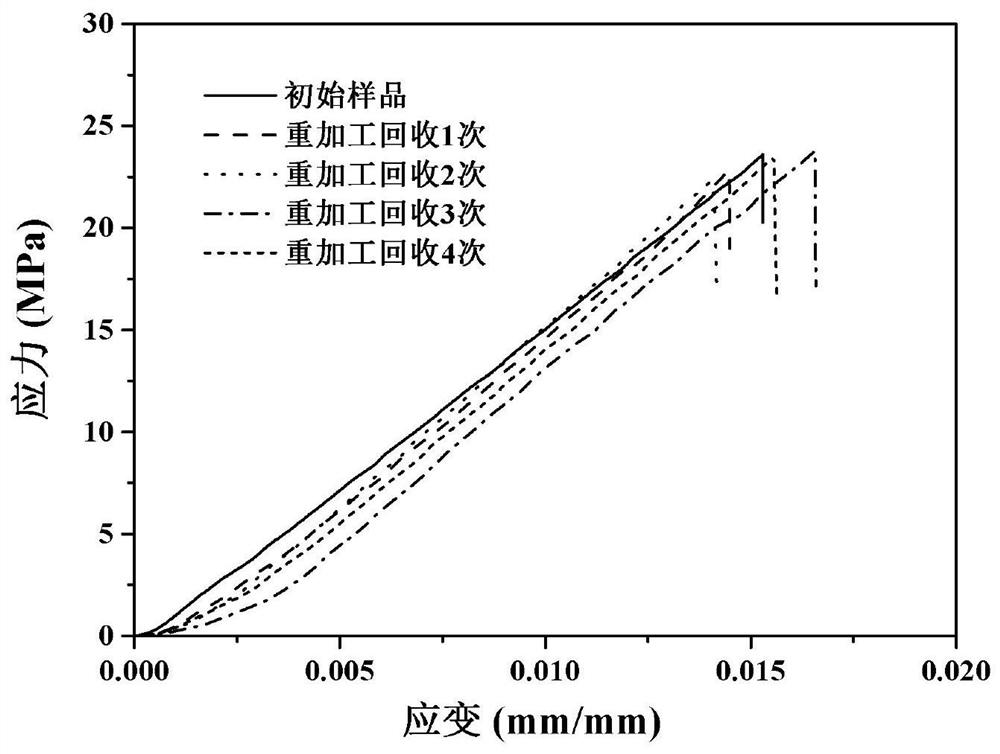

A smart material and self-adaptive technology, applied in the direction of nickel organic compounds, copper organic compounds, cobalt organic compounds, etc., can solve the problems of high bond energy and adverse effects of polymer materials on aging resistance, and achieve high mechanical stiffness and excellent reliability. The effect of high recovery and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Preparation of multidentate flexible ligands: Add 50.00g of pentaerythritol tetra-3-mercaptopropionate into a flask, then add 100mL of tetrahydrofuran as a solvent, control the reaction temperature at room temperature, stir at a speed of 100r / min, and stir for 30min until completely dissolved; Add 44.20g of N-allylimidazole and 1.05g of benzoin dimethyl ether to the above solution as a photoinitiator, use 365nm wavelength of ultraviolet radiation, control the reaction temperature at room temperature under sealed conditions, stir at a speed of 200r / min, and react for 60min to obtain A solution containing a multidentate flexible ligand;

[0049] Preparation of metal salt solution: Take 17.45g of copper chloride, add 50mL of methanol as a solvent, and mix evenly by ultrasonic, ultrasonic power 120W, ultrasonic time 30min, ultrasonic temperature room temperature;

[0050] Add the metal salt solution into the above-mentioned solution containing multidentate flexible ligands ...

Embodiment 2

[0054] Preparation of multidentate flexible ligands: Add 50.00g of pentaerythritol tetra-3-mercaptopropionate into a flask, then add 100mL of tetrahydrofuran as a solvent, control the reaction temperature at room temperature, stir at a speed of 100r / min, and stir for 30min until completely dissolved; 29.05g of acrylamide and 1.05g of benzoin dimethyl ether (DMPA) were added to the above solution as photoinitiators, and ultraviolet radiation with a wavelength of 365nm was used to control the reaction temperature at room temperature under sealed conditions, the stirring speed was 200r / min, and the reaction was carried out for 180min to obtain A solution of a multidentate flexible ligand;

[0055] Preparation of metal salt solution: take 13.26g of nickel chloride, add 50mL of methanol as a solvent, mix well by ultrasonic, ultrasonic power 120W, ultrasonic time 2h, ultrasonic temperature room temperature;

[0056] Add the metal salt solution into the solution containing multi-dent...

Embodiment 3

[0059] Preparation of multidentate flexible ligands: Add 50.00g of pentaerythritol tetra-3-mercaptopropionate into a flask, then add 100mL of tetrahydrofuran as a solvent, control the reaction temperature at room temperature, stir at a stirring speed of 200r / min, and stir for 10min until completely dissolved; Add 29.47g of acrylic acid and 0.98g of benzoin ethyl ether to the above solution as a photoinitiator, adopt ultraviolet radiation with a wavelength of 365nm, control the reaction temperature at room temperature under sealed conditions, stir at a speed of 100r / min, and react for 180min to obtain a polydentate flexible ligand. solution;

[0060] Preparation of metal salt solution: take 27.89g of zinc chloride, add 50mL of methanol as a solvent, mix well by ultrasonic, ultrasonic power 30W, ultrasonic time 120min, ultrasonic temperature room temperature;

[0061] Add the metal salt solution into the solution containing the multi-dentate flexible ligand by dropwise addition,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com