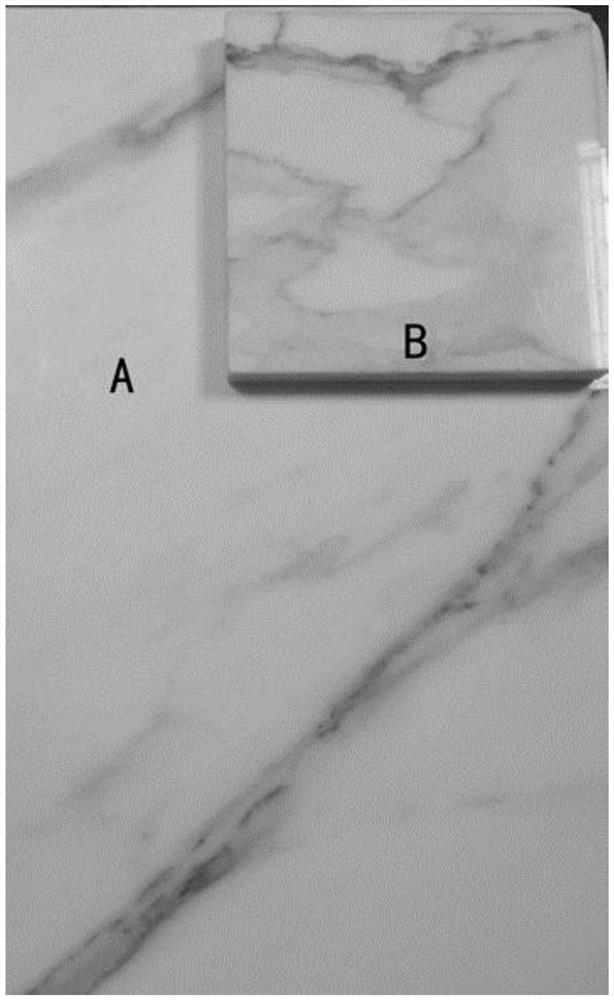

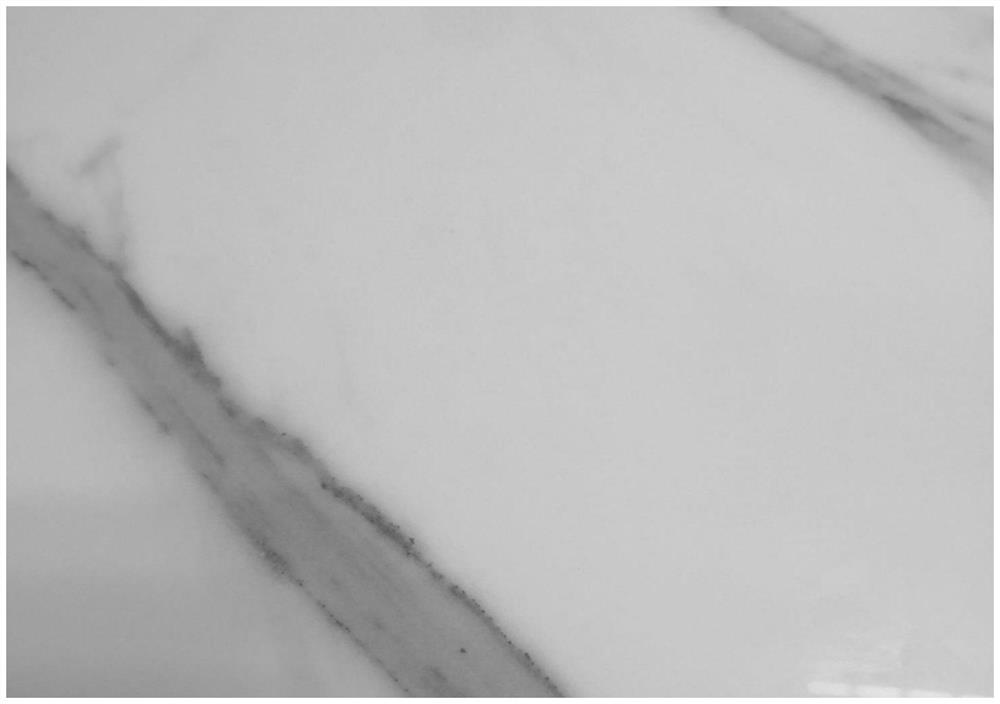

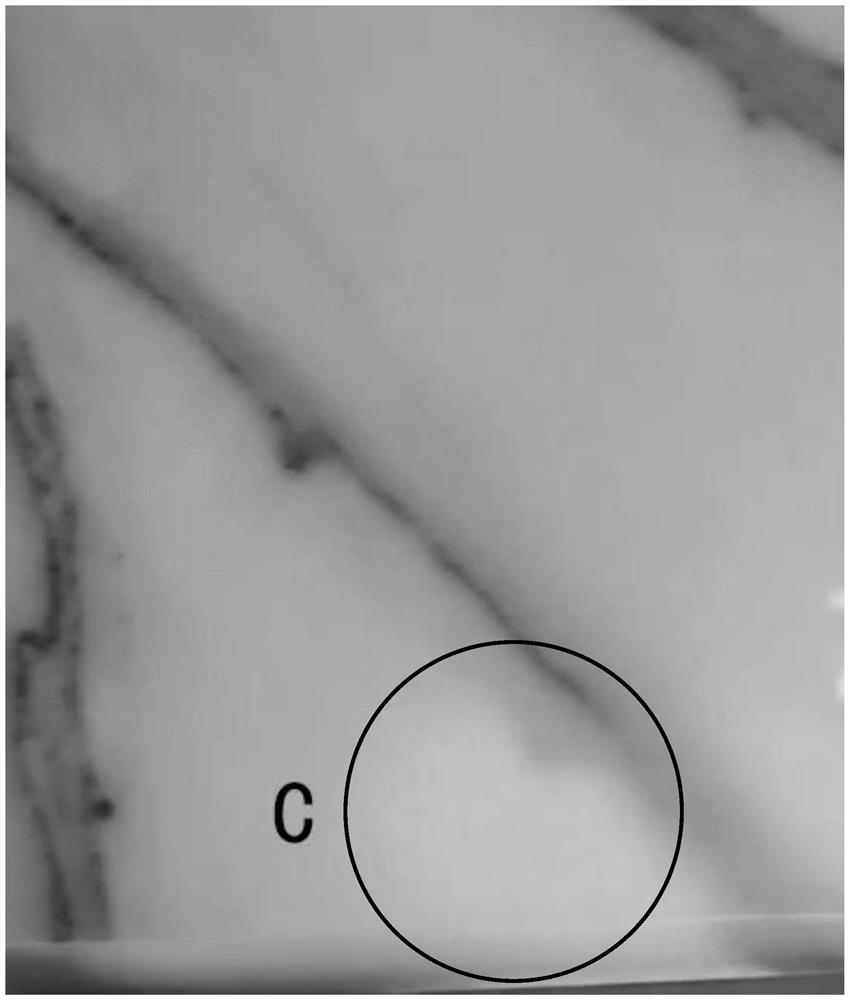

Ceramic plate with jade fish belly white effect, blank, preparation method and application

A fish maw white and ceramic plate technology, which is applied in the field of ceramic plates, can solve the problems of rigid decoration, damage, and insufficient drying strength of ultra-white blanks, etc., and achieve the effect of fine texture and fine texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] A method for preparing a blank with a jade-quality fish-belly effect, which is used to prepare the blank with a jade-quality fish-belly effect in any of the above embodiments, comprising the following steps:

[0051] Step (1): batching the raw materials of the billet, ball milling, impurity removal, spray drying and aging to obtain the billet powder;

[0052] The process parameters of the ball mill are: adding water to the ball is 33-37% of the dry material, the specific gravity of the ball slurry is 1.65-1.71, and the flow rate is 60-80 seconds;

[0053] The process parameters of spray drying are: moisture control is 9-10.4%; bulk density is 0.93-0.96; particle size gradation range: 20 mesh: ≤2%; 40 mesh: 40-50%; 60 mesh: 35-50%; 100 mesh: ≤15%; below 100 mesh: <2%.

[0054] In this solution, different types of blanks can be prepared according to the needs. For example, through a single step (1), ultra-white transparent materials can be prepared; in addition, this sol...

Embodiment A

[0077] The raw materials used in the frit include albite, potassium feldspar, quartz powder, alumina, zinc oxide, calcite, calcite, soda ash, barium carbonate, calcium fluoride, apatite, etc., which are mixed and melted at 1530°C , After water quenching, crystallization frit was obtained. Frit, by mass percentage, includes: 58.13% SiO 2 , 14.72% Al 2 o 3 , 3.89% of CaO, 5.2% of MgO, 0.69% of K 2 O, 5.89% Na 2 O, 4.06% ZnO, 4.42% BaO, 0.49% P 2 o 5 and 2.51% CaF 2 .

[0078] Billet raw material, by weight, addition situation is as shown in table 1; The iron content of ultra-white kaolin, high plastic clay and high white ball clay is all≤0.2%; The iron content of high white potassium sand and high white sodium sand is all ≤0.1%. The plasticity index of high plastic clay is 15, and the dry flexural strength is 9MPa. Ball milling process parameters: moisture 35%, specific gravity 1.70, flow rate 70 seconds, 250 mesh sieve residue 0.6.

[0079] The billet raw material fo...

Embodiment B

[0093] The raw materials used in the frit include albite, potassium feldspar, quartz powder, alumina, zinc oxide, calcite, calcite, soda ash, barium carbonate, calcium fluoride, apatite, etc., which are mixed and melted at 1530°C , After water quenching, crystallization frit was obtained. Frit, by mass percentage, includes: 58.13% SiO 2 , 14.72% Al 2 o 3 , 3.89% of CaO, 5.2% of MgO, 0.69% of K 2 O, 5.89% Na 2 O, 4.06% ZnO, 4.42% BaO, 0.49% P 2 o 5 and 2.51% CaF 2 .

[0094] Billet raw materials, in parts by weight, include: 17 parts of ultra-white kaolin, 10 parts of high-plastic clay, 15 parts of high-white ball clay, 2 parts of high-white bentonite, 7 parts of ultra-white quartz sand, 15 parts of fused blocks, 24 parts of high white potassium sand, 22 parts of high white sodium sand, 1.5 parts of wollastonite, 3 parts of talc mud and 0.35 parts of body strengthening agent. The iron content of ultra-white kaolin, high plastic clay, high white ball clay, high white po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Modulus of rupture | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com