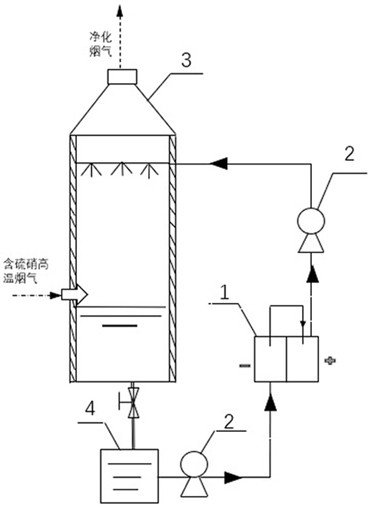

Method and device for circularly purifying sulfur dioxide and nitrogen oxide in flue gas

A technology of sulfur dioxide and nitrogen oxides is applied in the field of flue gas purification, which can solve the problems of complex process and catalyst poisoning, and achieve the effects of low cost, strong feasibility and good treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

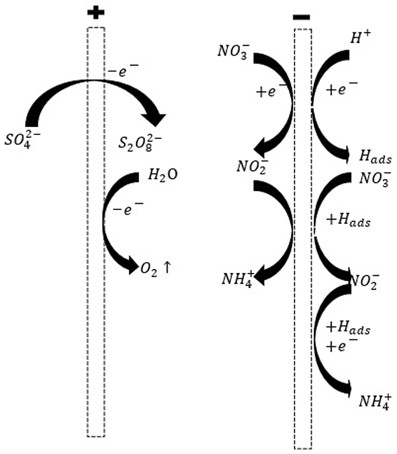

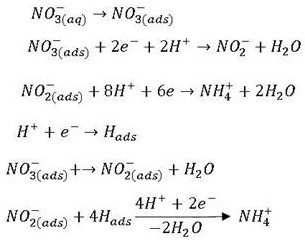

Method used

Image

Examples

Embodiment 1

[0044] Circulate and purify the flue gas produced by a thermal power plant, in which SO 2 , NO X The concentrations were 2635 mg / m 3 , 383 mg / m 3 , The temperature of the flue gas entering the absorption tower is 85°C. The cathodic chamber and the anode chamber of the electrolytic reactor use perfluorosulfonic acid cation exchange membrane as the diaphragm, and a solution containing 1 mol / L ammonium sulfate as the anolyte to maintain the pH of the anolyte at 2~3, and the cathode is made of titanium-based plating. Platinum electrode, the anode is made of titanium-based cobalt tetroxide plated electrode, and the current density of both cathode and anode is 8 mA / cm 2 , the electrolysis time is 3.0 h, and the liquid-gas ratio of flue gas desulfurization and denitrification is 25 L / m 3 , the result on the system of the desulfurization and denitrification system in the small-scale purification flue gas is: the SO in the flue gas 2 and NO X The simultaneous removal efficiencies...

Embodiment 2

[0046] Circulate the flue gas produced by a coking plant to purify sulfur dioxide and nitrogen oxides in the flue gas, among which SO 2 , NO X The concentrations were 800 mg / m 3 , 600 mg / m 3 , the temperature of the flue gas entering the absorption tower is 70°C. The cathodic chamber and the anode chamber of the electrolytic reaction chamber use perfluorosulfonic acid cation exchange membrane as the diaphragm, and use the solution containing 2 mol / L ammonium sulfate as the anolyte to maintain the pH of the anolyte at 2~3, and the cathode is made of titanium-based plating. Platinum electrode, the anode is made of titanium-based cobalt tetroxide plated electrode, and the current density of both cathode and anode is 10 mA / cm 2 , the electrolysis time is 4.0 h, and the liquid-gas ratio of flue gas denitrification is 25 L / m 3 , the result on the system of the desulfurization and denitrification system in the small-scale purification flue gas is: the SO in the flue gas 2 and NO...

Embodiment 3

[0048] Circulate the flue gas produced by a steel plant to purify sulfur dioxide and nitrogen oxides in the flue gas, among which SO 2 , NO X The concentrations were 2457 mg / m 3 、300mg / m 3 The temperature of the flue gas entering the absorption tower is 85°C. The cathodic chamber and the anode chamber of the electrolytic reactor use perfluorosulfonic acid cation exchange membrane as the diaphragm, and use the solution containing 3 mol / L ammonium sulfate as the anolyte to maintain the pH of the anolyte at 2~3, and the cathode is made of titanium-based plating. Platinum electrode, the anode is made of titanium-based cobalt tetroxide plated electrode, and the current density of both cathode and anode is 10 mA / cm 2 , the electrolysis time is 4.0 h, and the liquid-gas ratio of flue gas denitrification is 25 L / m 3 , the result on the system of the desulfurization and denitrification system in the small-scale purification flue gas is: the SO in the flue gas 2 and NO X The simul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com