Preparation method of benzotriazole diethyl phosphate

A technology of benzotriazole diethyl phosphate and benzotriazole, which is applied in the field of preparation of benzotriazole diethyl phosphate, can solve the problems of reaction pollution, use of toxic raw materials, etc., and achieves easy separation, The effect of mild conditions and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

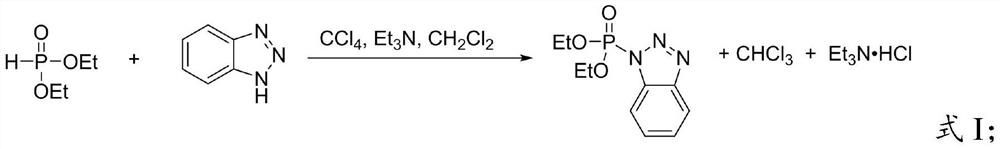

Problems solved by technology

Method used

Image

Examples

preparation example Construction

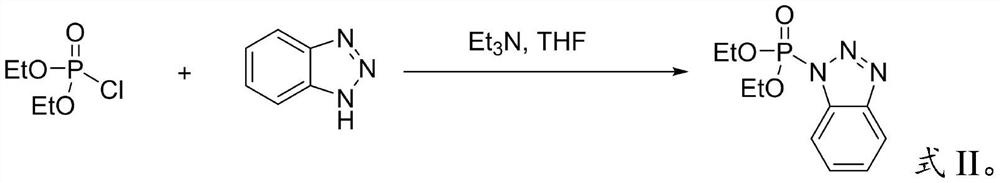

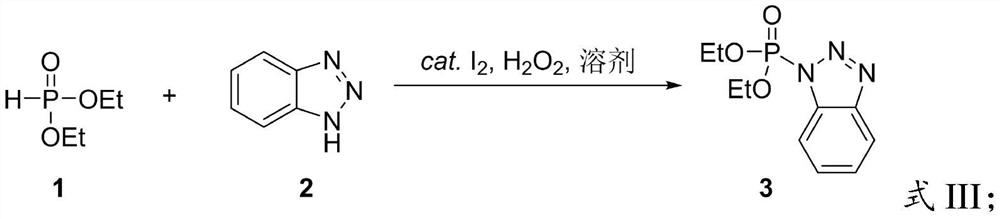

[0025] The invention provides a kind of preparation method of benzotriazole diethyl phosphate, comprising the following steps:

[0026] Diethyl phosphite, benzotriazole, oxidant and iodine catalyst are mixed for oxidative coupling reaction to obtain the benzotriazole diethyl phosphate; the oxidant is hydrogen peroxide or tert-butyl hydrogen peroxide alcohol, the iodine catalyst is I 2 or compounds containing iodide ions.

[0027] In the present invention, unless otherwise specified, the raw materials used are all commercially available products in this field.

[0028] In the present invention, the compound containing iodide ion is preferably sodium iodide, potassium iodide or tetrabutylammonium iodide.

[0029] In the present invention, the equivalent ratio of the iodine catalyst to benzotriazole is preferably 0.1˜0.2:1.

[0030] In the present invention, the equivalent ratio of diethyl phosphite to benzotriazole is preferably 1˜2:1.

[0031] In the present invention, the ...

Embodiment 1

[0049] A 100mL round bottom flask was fixed on a magnetic stirrer with a stand, and a rotor was added to the flask. Weigh 1.19g (10.0mmol) of benzotriazole with a balance, add 40mL of dichloromethane and 1.41mL (11.0mmol) of diethyl phosphite, add a catalytic amount of iodine 253mg (1.0mmol), add 1.24mL at room temperature 30% hydrogen peroxide (11.0 mmol). The rotating speed of the magnetic stirrer was 500 rpm, and the reaction was carried out at room temperature for 24 hours.

[0050] After the reaction is complete, transfer the reaction mixture solution to a separatory funnel, let it stand to separate layers, and keep the lower organic phase. Wash twice with saturated sodium bicarbonate solution and once with saturated sodium chloride solution. Pour the above-mentioned washed organic solution into an Erlenmeyer flask, and dry it with anhydrous sodium sulfate to remove the moisture in the solution. Vacuum suction filtration, the organic solution was placed on a rotary eva...

Embodiment 2

[0052] A 100mL round bottom flask was fixed on a magnetic stirrer with a stand, and a rotor was added to the flask. Weigh 1.19g (10.0mmol) of benzotriazole with a balance, add 40mL of dichloromethane and 1.41mL (11.0mmol) of diethyl phosphite, add catalytic amount of tetrabutylammonium iodide 369mg (1.0mmol), 1.24 mL of 30% hydrogen peroxide (11.0 mmol) was added at room temperature. The rotating speed of the magnetic stirrer was 500 rpm, and the reaction was carried out at room temperature for 24 hours.

[0053]After the reaction is complete, transfer the reaction mixture solution to a separatory funnel, let it stand to separate layers, and keep the lower organic phase. Wash twice with saturated sodium bicarbonate solution and once with saturated sodium chloride solution. Pour the above-mentioned washed organic solution into an Erlenmeyer flask, and dry it with anhydrous sodium sulfate to remove the moisture in the solution. Vacuum filtration, the organic solution was plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com