Genetically engineered bacterium for producing heparinase and application of genetically engineered bacterium in preparation of small-molecular heparin

A technology of genetically engineered bacteria and molecular heparin, which is applied in the field of preparation of small molecule heparin, can solve the problems of product biological activity impact, complex reaction conditions, product purification difficulties, etc., to ensure biological activity and physical and chemical properties, simple operation, avoid physical The effect of changing traits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

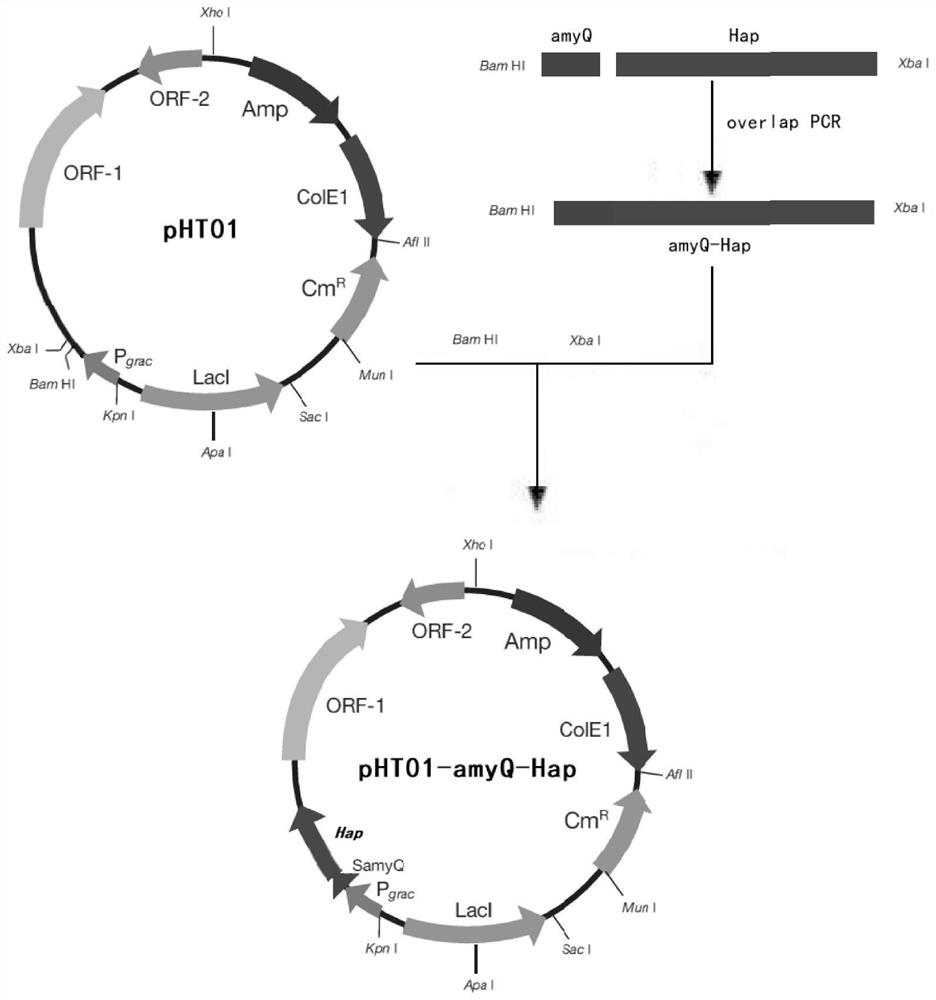

[0069] Embodiment 1: Construction of recombinant Bacillus subtilis

[0070] Amplification of the signal peptide amyQ: the gene fragment of the signal peptide amyQ was amplified using the plasmid pHT43 as a template. The PCR amplification system is 1 μL of genome, 4 μL of primer 1 and primer 2, 50 μL of KOD polymerase, ddH 2 O 41 μL, PCR reaction program: 94°C pre-denaturation for 4 min, 94°C denaturation for 2 min; then annealing at 62°C for 30 s, extension at 72°C for 0.2 min, cycle 35 times; extension at 72°C for 1 min. After gel electrophoresis, the PCR product was gel-cut and recovered with a column-type gel-slicing recovery kit to obtain a purified amyQ gene fragment.

[0071] Amplification of the heparinase gene: using the genome of P.heparinus ATCC13125 as a template, the gene fragment of the heparinase gene was amplified. The PCR amplification system is 1 μL of genomic DNA, 4 μL of primer 3 and primer 4, 50 μL of KOD polymerase, ddH 2 O 41 μL, PCR reaction program: ...

Embodiment 2

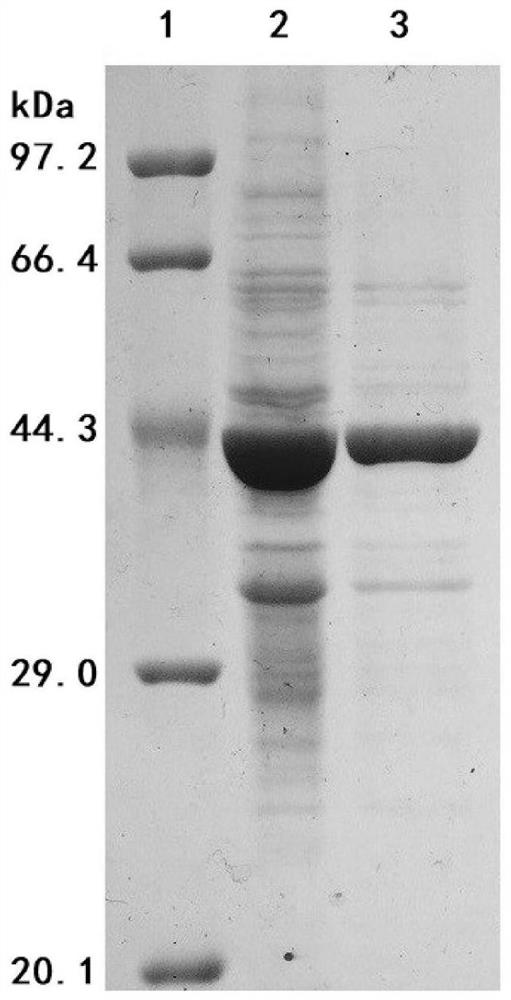

[0079] Example 2: Induced expression of heparanase

[0080]Inoculate the constructed recombinant Bacillus subtilis B. subtilis WB800-△spoOA-pHT01-amyQ-Hap in LB liquid medium containing chloramphenicol resistance, culture overnight at 37°C; then transfer to In 1L fermentation medium containing chloramphenicol, ferment for 2-4 hours to OD 660 When it reaches 0.8, add 20g / L lactose or 80mg / L IPTG to induce expression for 24h, and the activity of heparanase in the supernatant of the fermentation broth can reach 3200U / mL.

Embodiment 3

[0081] Embodiment 3: the heparanase activity assay of fermented liquid

[0082] Take 1 mL of fermentation broth and centrifuge, take 0.5 mL of fermentation supernatant and 1.5 mL of 25 g / L heparin (prepared with 0.02 mol / LTris-HCL, pH 7.5) respectively, add them to a quartz cuvette, and incubate the reaction at 30 ° C. Scan at 232nm for 1min, and calculate the slope of the reaction k(min -1 ). The formula for calculating the enzyme activity (U / L) of heparanase is as follows:

[0083]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com