Biomass-based papermaking reinforcing agent prepared by taking agricultural residues as raw materials, and preparation method and application thereof

A paper-making strengthening agent and residue technology, which is applied in the field of biomass-based paper-making strengthening agents, can solve the problems of undiscovered patent publications and few high-value-added utilization methods, and achieve the improvement of ring compressive strength, tensile strength, The effect of improving the tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

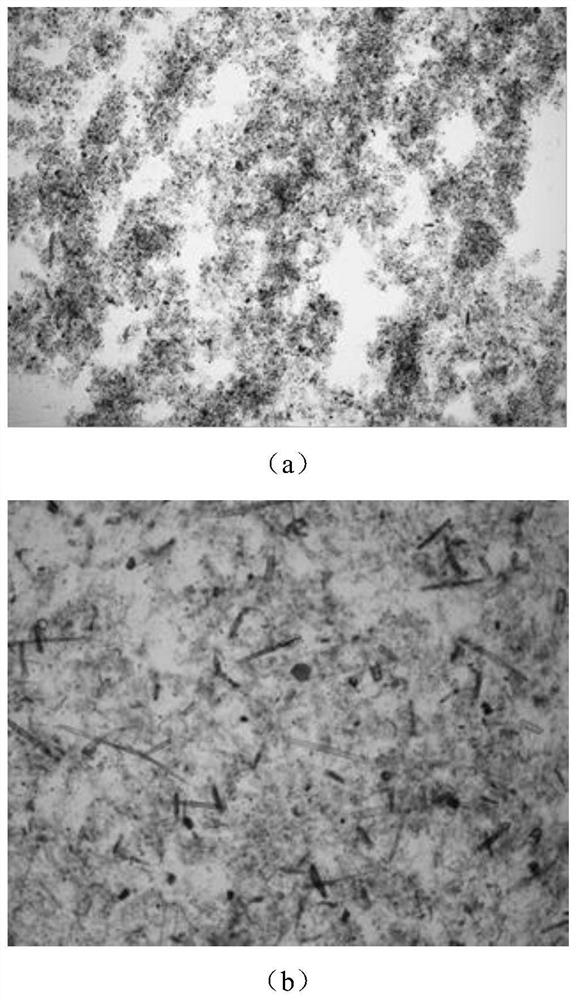

Embodiment 1

[0054] The air-dried corncobs are crushed into particles with a diameter less than 10mm, mixed with water at a solid-to-liquid ratio of 1:5 (w / v), and then placed in a reactor for autocatalytic hydrolysis treatment. The reaction temperature and holding time are respectively 180°C and 30min. After the self-catalyzed hydrolysis finishes, the obtained material is concentrated to 20% concentration and then ground under the gap of 0.15mm disc mill. After coarse grinding, the obtained material was further diluted with water to a material with a concentration of 1 wt%, and treated for 1 h at a cellulase dosage of 1.5 FPU / g substrate, 50° C., and pH 5. After the enzyme treatment, the colloid mill was used to micronize the obtained material for 20 minutes, and finally a biomass-based paper-making strengthening agent was obtained. The optical microscope photos of it are as follows: figure 1 (a) shown.

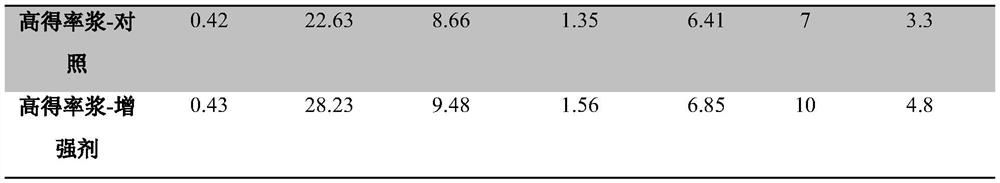

[0055] The above-mentioned biomass-based papermaking strengthening agent was added...

Embodiment 2

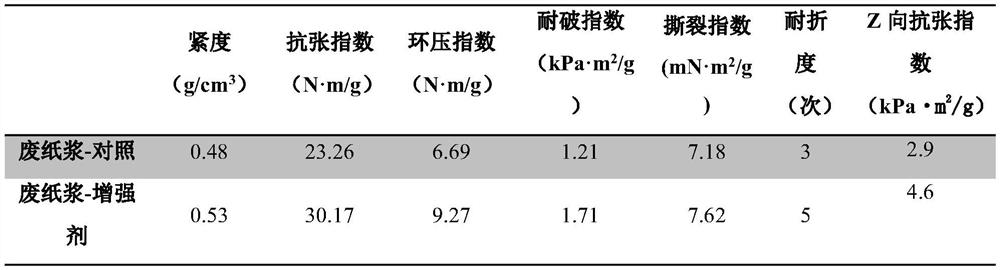

[0060] The collected corn stalks are separated from the skin and core to obtain the core pith, mixed with water at a solid-to-liquid ratio of 1:6 (w / v), and then placed in a reactor to start autocatalytic hydrolysis. The reaction temperature and holding time are controlled separately At 175°C and 45min. After the self-catalyzed hydrolysis was completed, the obtained material was concentrated to a concentration of 30 wt%, and ground under a 0.15mm disc grinding gap. After the coarse grinding is finished, the obtained material is diluted with water to a material with a concentration of 3wt%, and is treated for 2 hours at a cellulase dosage of 0.6 FPU / g substrate, 50° C., and pH 5. After the enzyme treatment is finished, it is further diluted with water to a material with a concentration of 1wt%, and the resulting material is micronized for 30 minutes under the condition of 30MPa by a high-pressure homogenizer, and finally a biomass-based papermaking strengthening agent is obtain...

Embodiment 3

[0063] The bagasse produced in the sugar factory is semi-dry screened to obtain cane pith, mixed with water at a solid-to-liquid ratio of 1:10 (w / v), and then placed in a reactor to start autocatalytic hydrolysis, reaction temperature and holding time Controlled at 170°C and 60min respectively. After the self-catalyzed hydrolysis finishes, the gained material is concentrated to a concentration of 30wt%, and ground under a 0.20mm disc grinding gap. After coarse grinding, the obtained material was diluted with water to a concentration of 3 wt%, and treated for 2 hours at a cellulase dosage of 0.8 FPU / g substrate, 50° C., and pH 5. After the enzyme treatment is finished, it is further diluted with water to a material with a concentration of 1wt%, and the resulting material is micronized for 40 minutes by a high-pressure homogenizer under 60MPa conditions to finally obtain a biomass-based papermaking strengthening agent.

[0064] The above-mentioned biomass-based papermaking stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com