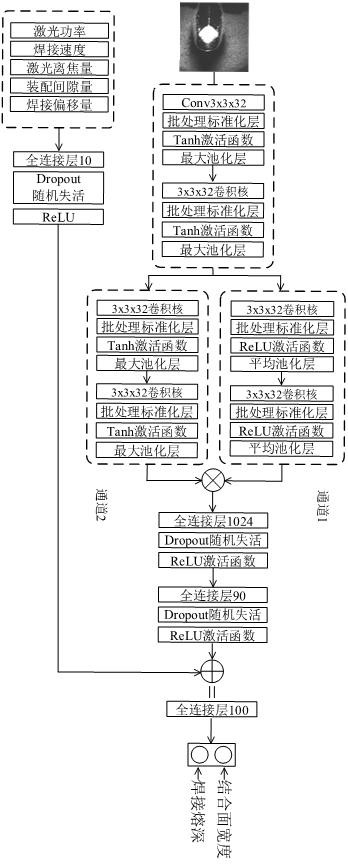

Weld joint forming prediction method based on complementary two-channel convolutional neural network

A convolutional neural network and welding seam forming technology, which is applied in the field of material processing engineering to achieve the effect of saving time, low definition requirements, and avoiding information loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the examples.

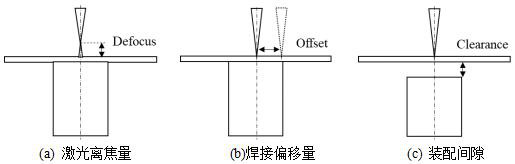

[0044] In the present invention, TA15 titanium alloy is used as the welding base material, and the form of T-joint is taken as an example; the size of the skin sample of the T-joint used is 150mm×50mm×1.5mm, and the size of the rib plate sample is 150mm×30mm×10mm.

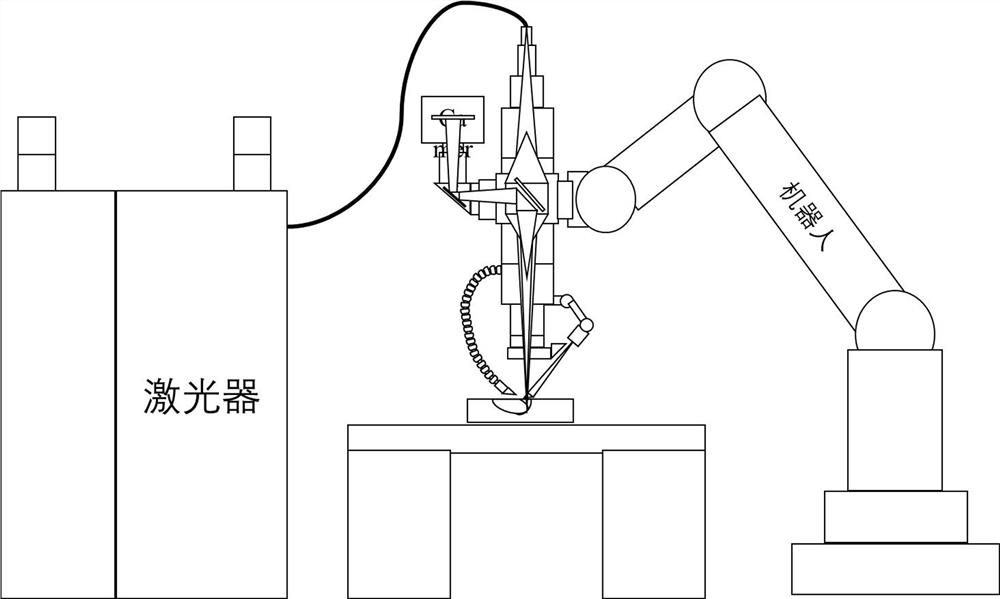

[0045] Using laser welding molten pool coaxial monitoring system, such as figure 2 As shown, the laser used can be fiber laser, CO 2 Lasers, semiconductor lasers, etc. The motion system used for welding can be mechanical arms, CNC machine tools, CNC guide rails, etc. The cameras used can be CCD cameras, CMOS cameras, etc. The auxiliary light source can be fiber lasers, xenon lamps, etc. The protective gas can be argon gas, helium, helium-argon mixture, etc.

[0046] The specific experimental method of laser welding seam shape prediction method based on complementary dual-channel convolutional neural network is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com