Two-dimensional metal/COF-based photocatalytic composite material carrying metal nanoparticles as well as synthesis method and application of two-dimensional metal/COF-based photocatalytic composite material

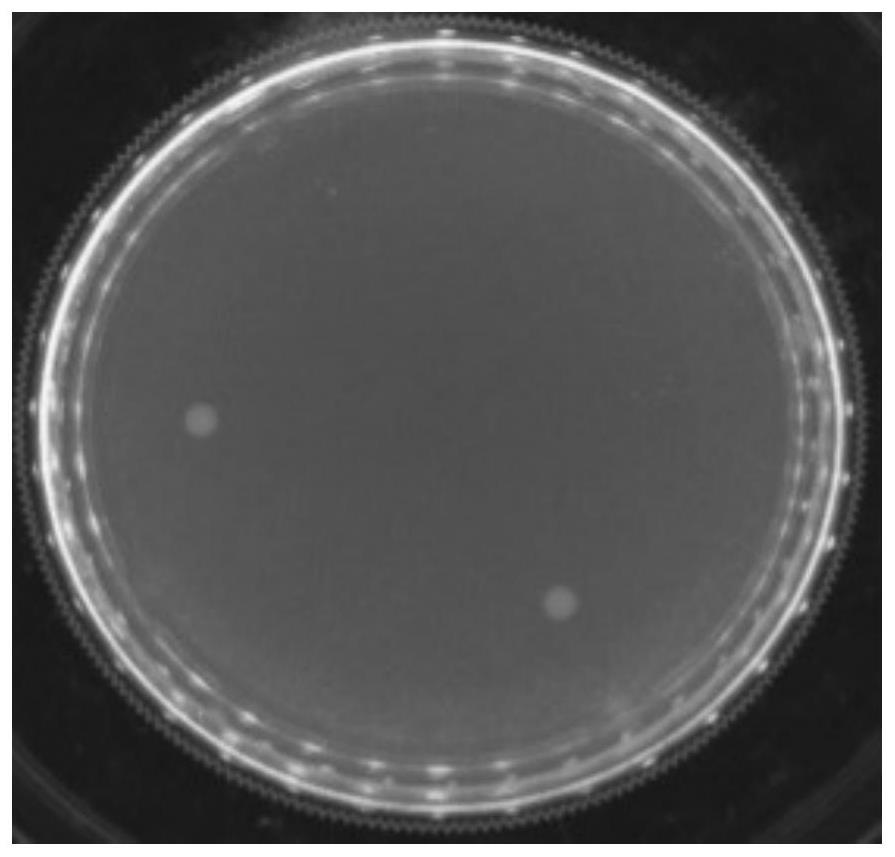

A technology of metal nanoparticles and composite materials, applied in the field of two-dimensional photocatalysis and antifouling, can solve the problems of large forbidden band width and short carrier lifetime, and achieve the effect of reducing release rate, stable material structure, and promoting transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

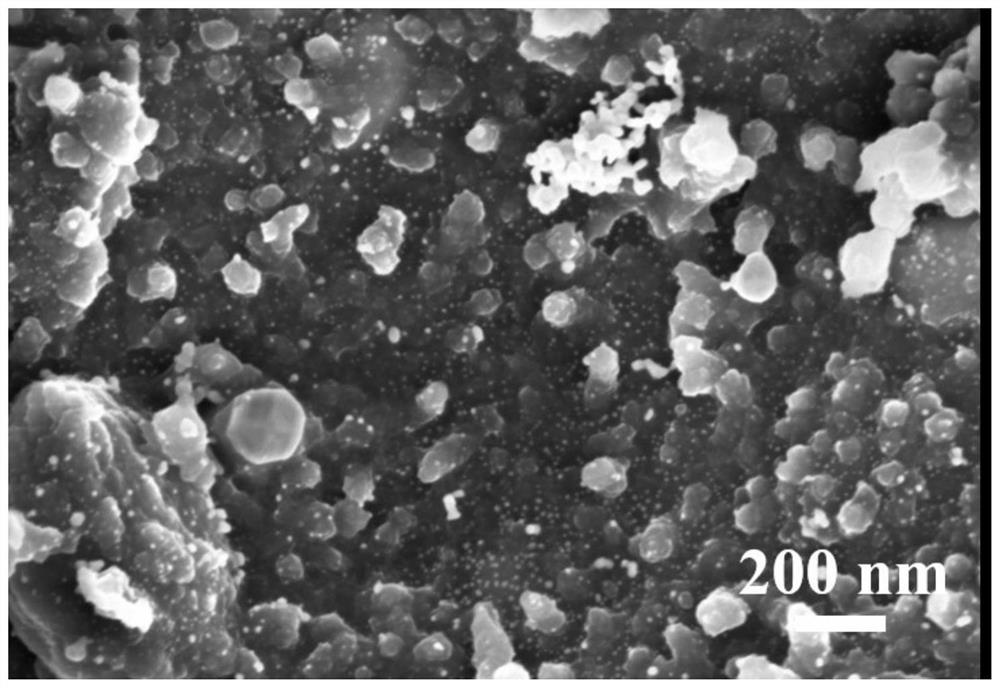

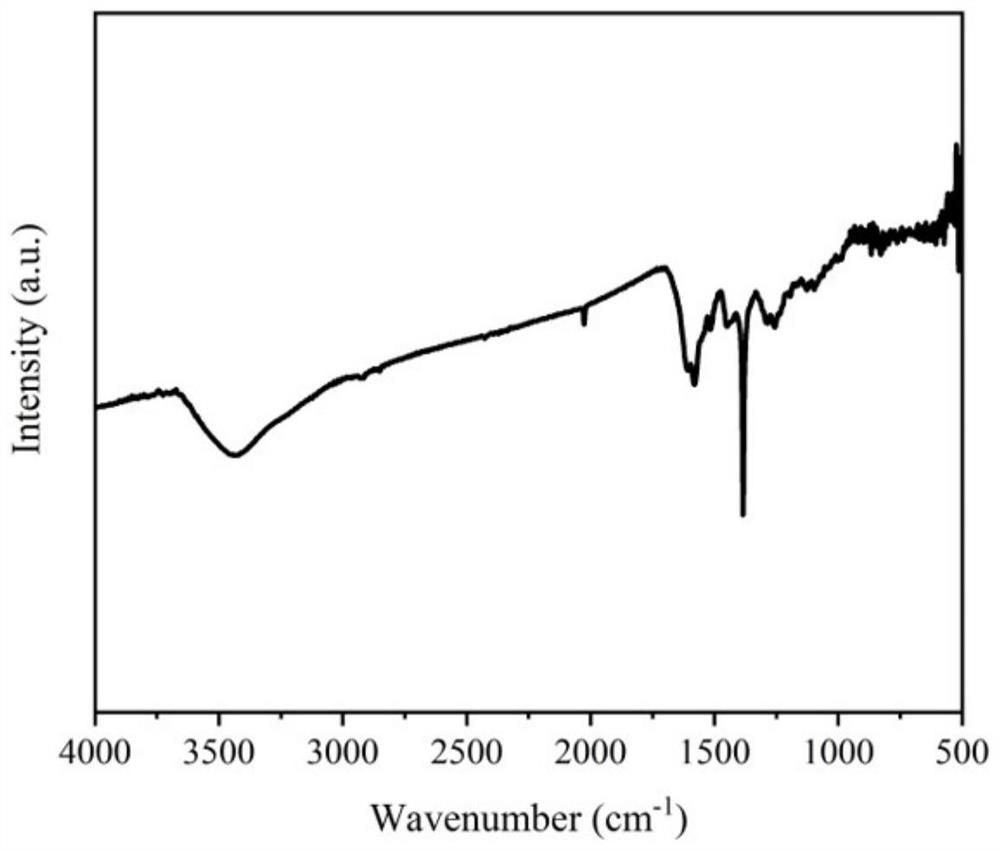

[0058] A two-dimensional metal / COF-based photocatalytic composite material loaded with metal nanoparticles, the specific steps of its synthesis method are as follows:

[0059] (1) Amination of two-dimensional metal materials: 60 mg of few-layer Ti 3 C 2 -MXene was dissolved in 15 mL of ethanol and deionized water with a volume ratio of 1:4, stirred thoroughly for 30 minutes, and then slowly added 200 microliters of 3-aminopropyltriethoxysilane at a temperature of 30°C and a rotation speed of Stirred at 600rpm for 20h, the resulting sample was lyophilized.

[0060] (2) In situ composite growth of two-dimensional materials: the prepared aminated Ti 3 C 2 -MXene, 70mg of triacylphloroglucinol, 67mg of p-aminodimethylaniline, 1.5mL of mesitylene, 1.5mL of dioxane, 0.5mL of 3M acetic acid aqueous solution were placed in a pyrex glass tube at 25°C , stirring at 750rpm for 1h to disperse the sample evenly. The tubes were then flash frozen at 77K (liquid N2 bath) and degassed thr...

Embodiment 2

[0064] (1) Amination of two-dimensional metal materials: 100 mg of few-layer Ti 2 C-MXene was dissolved in 50 mL of ethanol, and then 800 μL of γ-aminopropyltriethoxysilane was gradually added, the temperature was 30 ° C, the rotation speed was 800 rpm, and the mixture was stirred for 22 h. The obtained sample was washed with ethanol and then freeze-dried.

[0065] (2) In situ composite growth of two-dimensional materials: the prepared aminated Ti 2 30mg of C-MXene, 60mg of potassium hydroxide, and 70mg of triformylphloroglucinol were dissolved in 10mL of deionized water, placed in a three-necked flask, and added in an oil bath at 140°C at 600rpm under nitrogen atmosphere for 30 minutes. Then, 50 mg of p-phenylenediamine was dissolved in 15 mL of N,N-dimethylformamide, and the mixed solution was added into a three-necked flask, and the reaction was continued for 14 hours while maintaining the original addition state. The reacted solution was centrifuged 5 times with ethanol, ...

Embodiment 3

[0069] (1) Amination of two-dimensional metal materials: Dissolve 5 g of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane in 20 g of a solution with a mass ratio of ethanol to water of 9:1, and stir thoroughly well mixed. 250mg few-layer Mo 2 C was dissolved in the mixed solution at a temperature of 30°C and a rotation speed of 800rpm, and stirred for 24h. The resulting solution was then centrifuged three times with an aqueous ethanol solution, and the precipitate was lyophilized.

[0070] (2) In situ composite growth of two-dimensional materials: 1 mL of 3M acetic acid, 3 mL of m-trimethylbenzene, 3 mL of dioxane, 63 mg of triformylphloroglucinol, prepared aminated Mo 2 27 mg of C, 50 mg of p-phenylenediamine were placed in a three-necked flask, and stirred for 28 hours under a nitrogen atmosphere at a temperature of 120° C. and a rotational speed of 800 rpm. After cooling to room temperature, the product was centrifuged three times with N, N-dimethylformamide and ethanol re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com