Production method of high-strength steel plate for engineering machinery

A high-strength steel plate and engineering machinery technology, applied in the field of metallurgy, can solve the problems of unfavorable uniform elongation, difficult elongation, high residual stress and micro stress, etc., and achieve excellent bending ability, shape and surface of the whole plate along the rolling direction. The effect of good quality and reasonable composition design ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

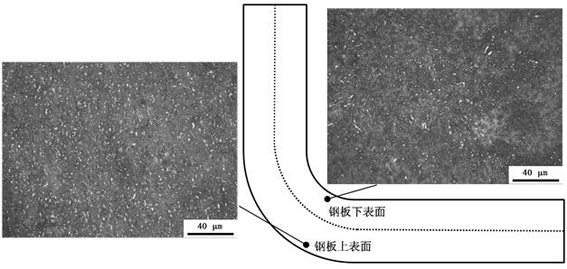

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below with embodiment.

[0058] The chemical composition, steel grade and plate thickness of the steel plate in the embodiment of the present invention are shown in Table 1, and the balance is Fe and unavoidable impurities.

[0059] The process steps of the steel plate in the embodiment of the present invention include: smelting (hot metal pretreatment), refining, continuous casting, rolling, heat treatment (normalizing pretreatment), and the key process steps include:

[0060](1) Smelting: A 150t top-bottom combined blowing converter is used for smelting. The molten iron in all examples is desulfurized by KR pretreatment. The selected coolant includes trimming and plate waste, as well as ferromolybdenum, nickel plate and copper plate. The slagging material includes lime , lightly burned dolomite, fluorite and iron ore, bottom-blown argon throughout the smelting process and tapping process, when the blowing process reaches...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com