Preparation of polyhydroxy fatty acid and application of polyhydroxy fatty acid in nano calcium carbonate coating

A polyhydroxy fatty acid, nano calcium carbonate technology, applied in the preparation of carboxylates, the preparation of organic compounds, chemical instruments and methods, etc., to achieve the effect of increasing the contact area, reducing production costs, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) 9, the synthetic method of 10-dihydroxystearic acid

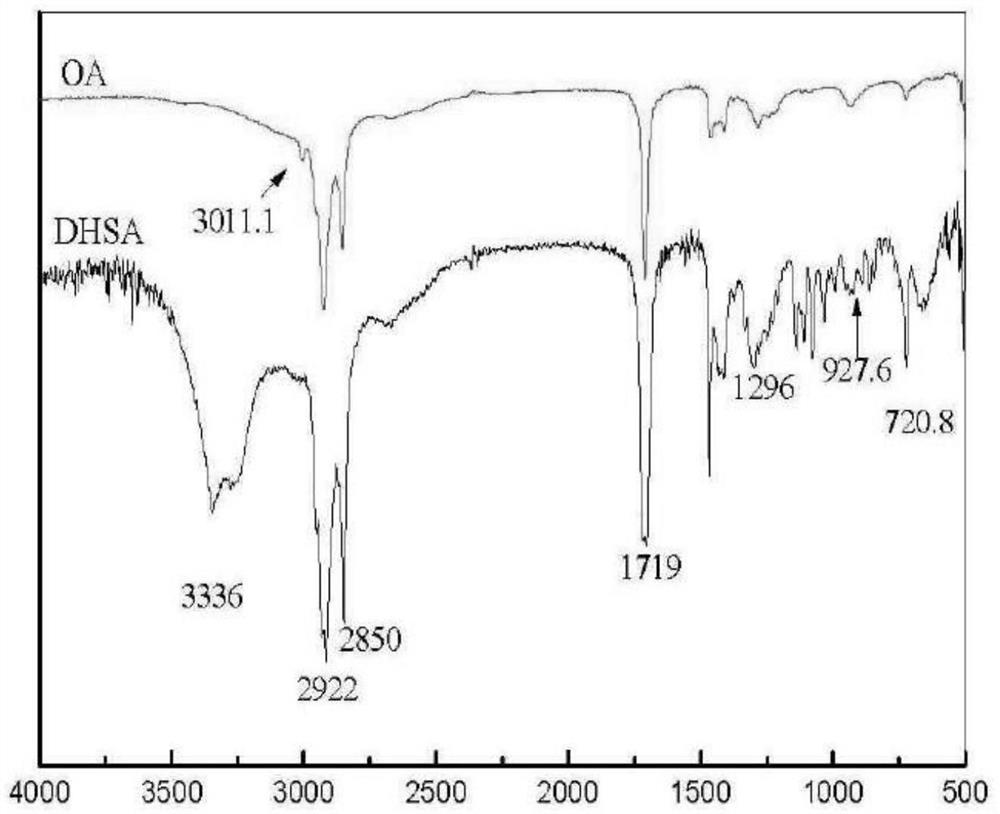

[0045] Add 100g of oleic acid and 63.04g of 88% formic acid supported by activated carbon into a three-port reactor, heat to 65°C, slowly add hydrogen peroxide and a compound solution of 60% methanol 73g dropwise, wherein the mass fraction of hydrogen peroxide is 30%, A total amount of 88g was added, stirred for 6h after the dropwise addition, and spin-dried under reduced pressure to obtain a light yellow oil phase 9,10-dihydroxystearic acid (DHSA), and the product was taken for infrared spectrum detection, as shown in figure 1 As shown, the result is displayed at 3336cm -1 There is a relatively obvious peak at the place, which belongs to the hydroxyl functional group in the molecular structure, so it can be judged that 9,10-dihydroxystearic acid has been synthesized.

[0046] (2) Application of 9,10-dihydroxystearic acid in nano-calcium carbonate coating

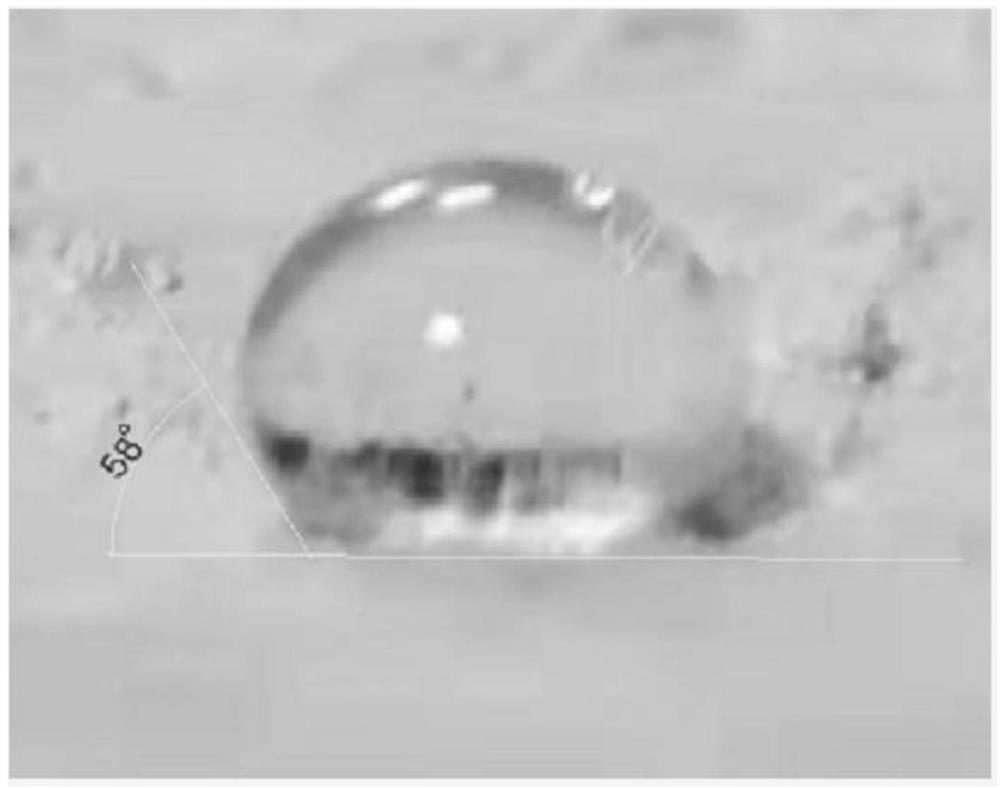

[0047] In a three-port reaction kettle, add 4.5g of 9,...

Embodiment 2

[0049] (1) 9,10,12,the synthetic method of 13-tetrahydroxystearic acid

[0050] Add 98.15g of linoleic acid in the three-port reactor, 63.04g of formic acid with a mass fraction of 88% supported by the resin, heat to 60°C, slowly add hydrogen peroxide and a compound solution with a mass fraction of 60% methanol 60g, wherein the mass fraction of hydrogen peroxide is It was 30%, and the total dosage was 88g. After the dropwise addition, it was stirred for 6 hours, and spin-dried under reduced pressure to obtain the light yellow oil phase 9,10,12,13-tetrahydroxystearic acid (THSA).

[0051] (2) Application of 9,10,12,13-tetrahydroxystearic acid in nano-calcium carbonate coating

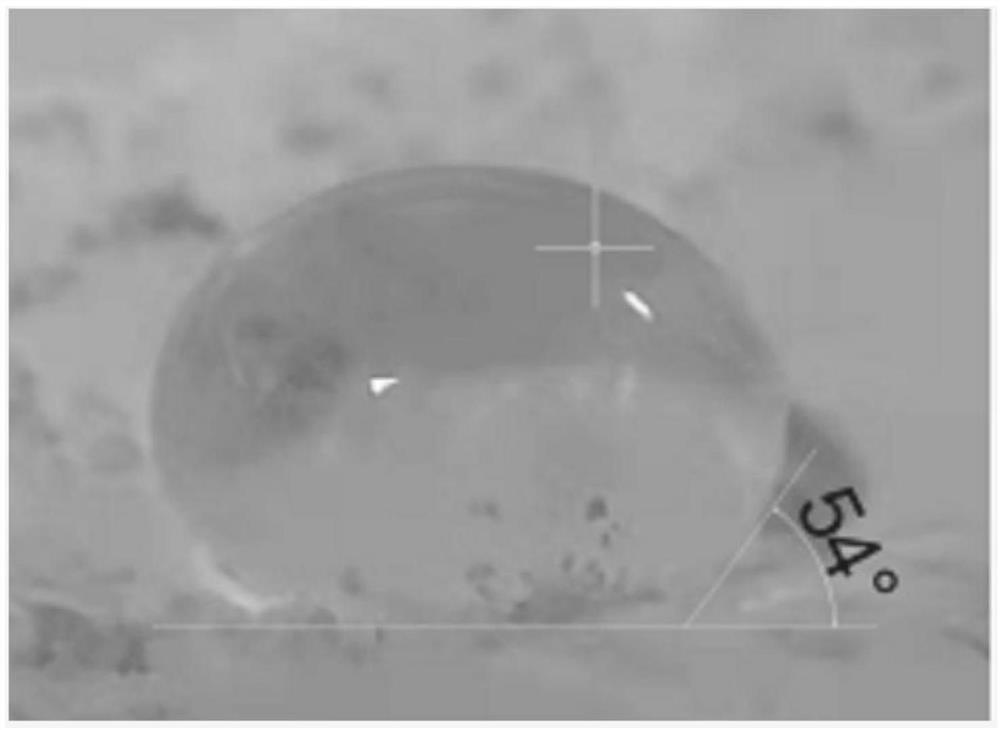

[0052] In a three-port reaction kettle, add 4.5g of 9,10,12,13-tetrahydroxystearic acid and 2.14g of 6mol / L NaOH solution, mix well, heat to 65°C, and keep for 40min for saponification reaction to obtain polyhydroxystearin Sodium bicarbonate, in 6.64g polyhydroxy sodium fatty acid reaction solution, add 1...

Embodiment 3

[0054] (1) The synthetic method of 9,10,12,13,15,16-hexahydroxystearic acid

[0055] Add 97.44g of linolenic acid, 63.04g of 88% formic acid supported by the resin in a three-port reactor, heat to 60°C, slowly add hydrogen peroxide and a compound solution of 60% methanol 73g dropwise, wherein the hydrogen peroxide mass fraction is 30% , a total dosage of 97.44g, stirred for 6 hours after the dropwise addition, and spin-dried under reduced pressure to obtain the tan oil phase 9, 10, 12, 13, 15, 16-hexahydroxystearic acid.

[0056] (2) Application of 9, 10, 12, 13, 15, 16-hexahydroxystearic acid in nano-calcium carbonate coating

[0057] In a three-port reaction kettle, add 4.5g of 9,10,12,13-tetrahydroxystearic acid and 1.95g of 6mol / L NaOH solution, mix well, heat to 65°C, and keep for 40min for saponification reaction to obtain polyhydroxystearin Sodium acid, add 1065g of nano-calcium carbonate cooked slurry to 6.45g of polyhydroxysodium fatty acid reaction solution, mix eve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com