Preparation method of lithium ferrous oxalate ion battery negative electrode material with exposed specific oriented crystal faces

A lithium ferrous oxalate and ion battery technology, which is applied in battery electrodes, carboxylate preparation, carboxylate preparation, etc., to achieve low cost and enhance energy storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a negative electrode material for a ferrous oxalate lithium ion battery exposing a specific orientation crystal plane, the specific steps of which are as follows:

[0025] Step 1. Disperse the ferric hydroxide precursor material in a mixed solution composed of 30ml ethanol and 100ml deionized water through an ultrasonic cleaner to obtain a uniformly dispersed mixed turbid solution; wherein, the volume ratio of the precursor material mass to the liquid solution For: 0.5 g: 130 ml;

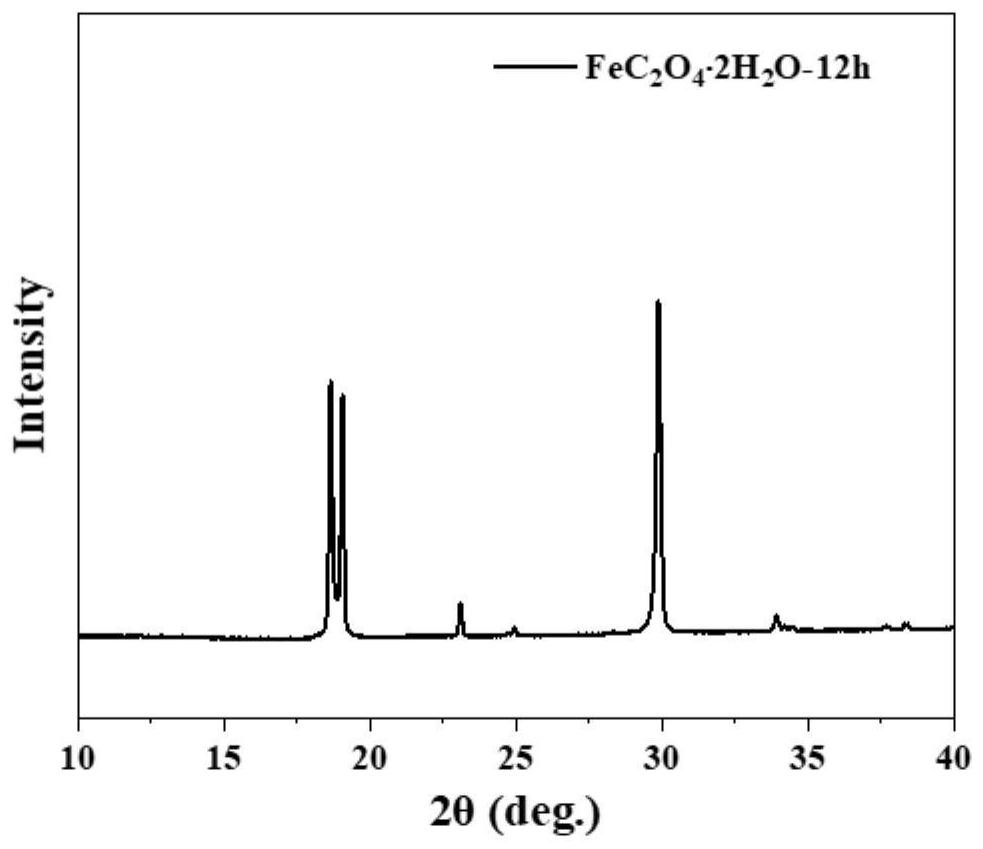

[0026] Step 2. Add 1.3 g of ascorbic acid and 4.0 g of oxalic acid to the uniformly dispersed turbid liquid in step 1, and react at 80° C. for 12 h; after the reaction is completed, filter, wash and dry to obtain a ferrous oxalate material containing crystal water ;

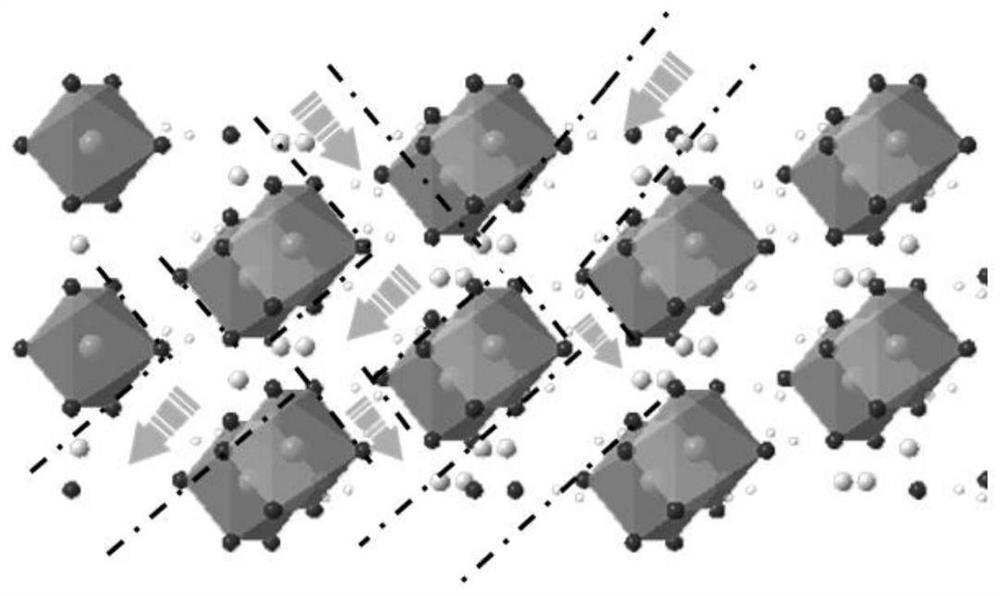

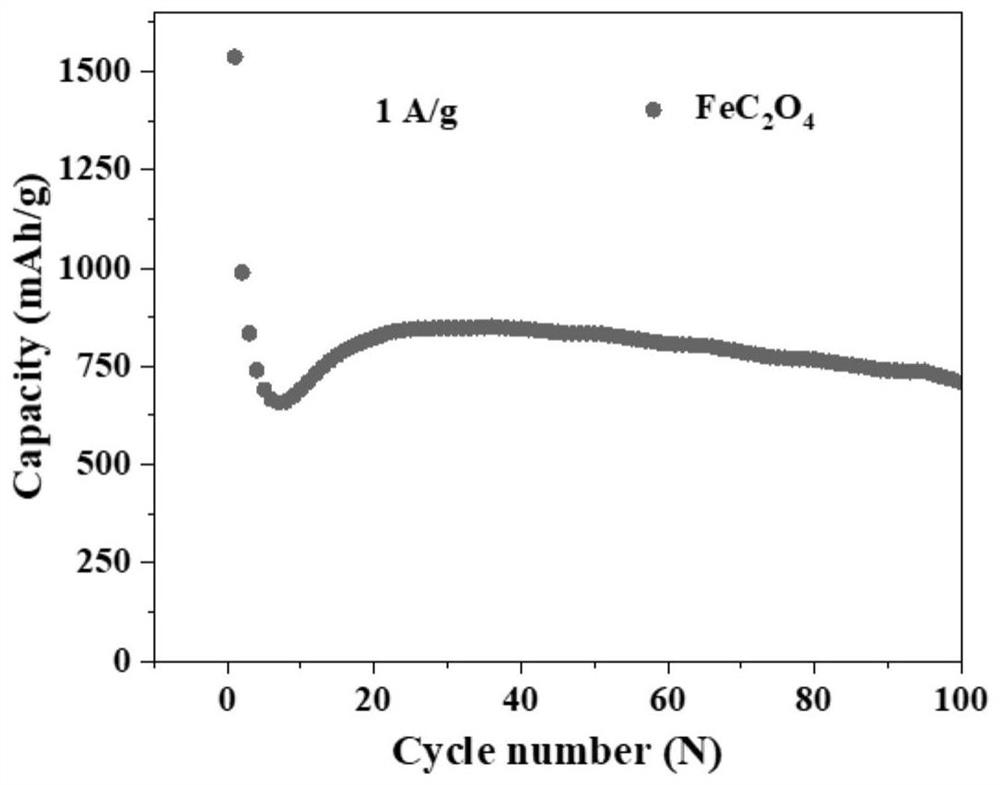

[0027] Step 3. Sintering the crystal water-containing ferrous oxalate material obtained in step 3 at 280° C. for 2 hours under an argon atmosphere to obtain a ferrous oxalate material with exposed (202) c...

Embodiment 2

[0030] A method for preparing a negative electrode material for a ferrous oxalate lithium ion battery exposing a specific orientation crystal plane, the specific steps of which are as follows:

[0031] Step 1. Disperse the ferric hydroxide precursor material in a mixed solution composed of 30ml ethanol and 100ml deionized water through an ultrasonic cleaner to obtain a uniformly dispersed mixed turbid solution; wherein, the volume ratio of the precursor material mass to the liquid solution For: 0.5 g: 130 ml;

[0032] Step 2. Add 1.3g of ascorbic acid and 4.0g of oxalic acid to the uniformly dispersed turbid liquid in step 1, and react at 80°C for 12 h; after the reaction is completed, filter, wash and dry to obtain crystal water exposure (202) Crystalline ferrous oxalate material;

[0033] Step 3. Sintering the crystal water-containing ferrous oxalate material obtained in step 3 at 280° C. for 2 hours under an argon atmosphere to obtain a ferrous oxalate material with expose...

Embodiment 3

[0037] A method for preparing a negative electrode material for a ferrous oxalate lithium ion battery exposing a specific orientation crystal plane, the specific steps of which are as follows:

[0038] Step 1. Disperse the ferric hydroxide precursor material in a mixed solution composed of 30ml ethanol and 100ml deionized water through an ultrasonic cleaner to obtain a uniformly dispersed mixed turbid solution; wherein, the volume ratio of the precursor material mass to the liquid solution For: 0.5 g: 130 ml;

[0039] Step 2. Add 1.3g of ascorbic acid and 4.0g of oxalic acid to the uniformly dispersed cloudy liquid in step 1, and react at 60°C for 24 hours; after the reaction is completed, filter, wash and dry to obtain (202) crystals containing crystal water Surface ferrous oxalate material;

[0040] Step 3. Sintering the crystal water-containing ferrous oxalate material obtained in step 3 at 280° C. for 2 hours under an argon atmosphere to obtain a ferrous oxalate material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com