Anti-CMAS protective layer for TBCs or EBCs, preparation method of anti-CMAS protective layer and protective structure obtained by anti-CMAS protective layer

A protective structure and protective layer technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve problems such as corrosion degradation, reduce the cost of preparation and processing, and achieve good thermal mechanical and chemical compatibility , Improve the effect of ultra-high temperature service stability and thermal cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

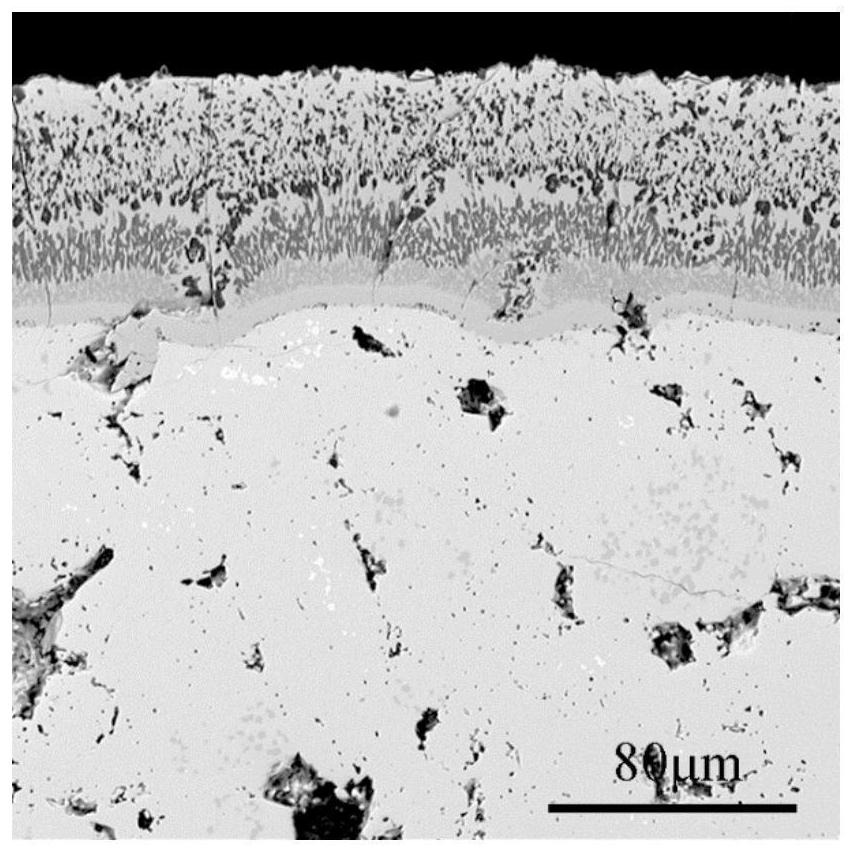

[0034] Using directionally solidified nickel-based superalloy DZ125 as the substrate, it is processed by wire cutting and grinding and polishing. Use 60-mesh corundum to sandblast the surface of the sample under compressed air, and then use acetone and absolute alcohol to perform ultrasonic cleaning in sequence to remove stains or adhered fine corundum grains on the surface of the sample and fully dry it. The NiCoCrAlYHf bonding layer was prepared on the surface of the DZ125 superalloy substrate by supersonic flame spraying or low-pressure plasma spraying, with a thickness of 120 μm. Subsequently, a layer of 150 μm thick YSZ ceramic thermal barrier layer was prepared on the adhesive layer by atmospheric plasma spraying, and then a 150 μm thick new high-temperature thermal barrier ceramic layer (chemical composition LaMgAl was prepared on the surface of the YSZ layer. 11 o 19 、Gd 2 Zr 2 o 7 , (Gd 0.9 Yb 0.1 ) 2 Zr 2 o 7 , La 2 (Ce 0.3 Zr 0.7 ) 2 o 7 、YSZ+xGd 2 o...

Embodiment 2

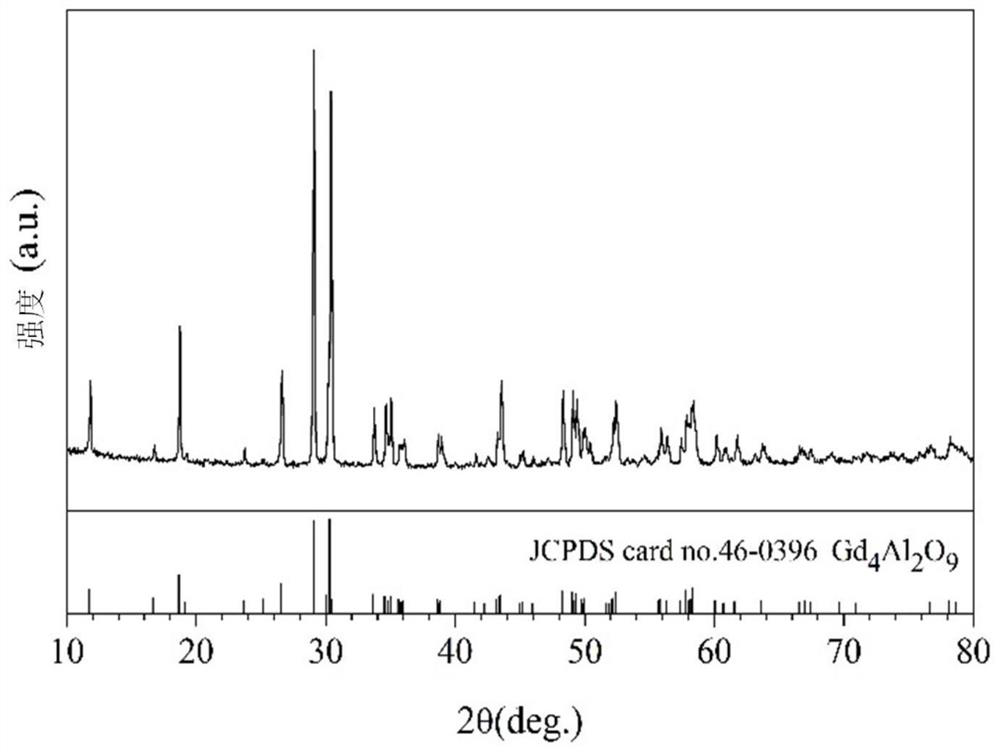

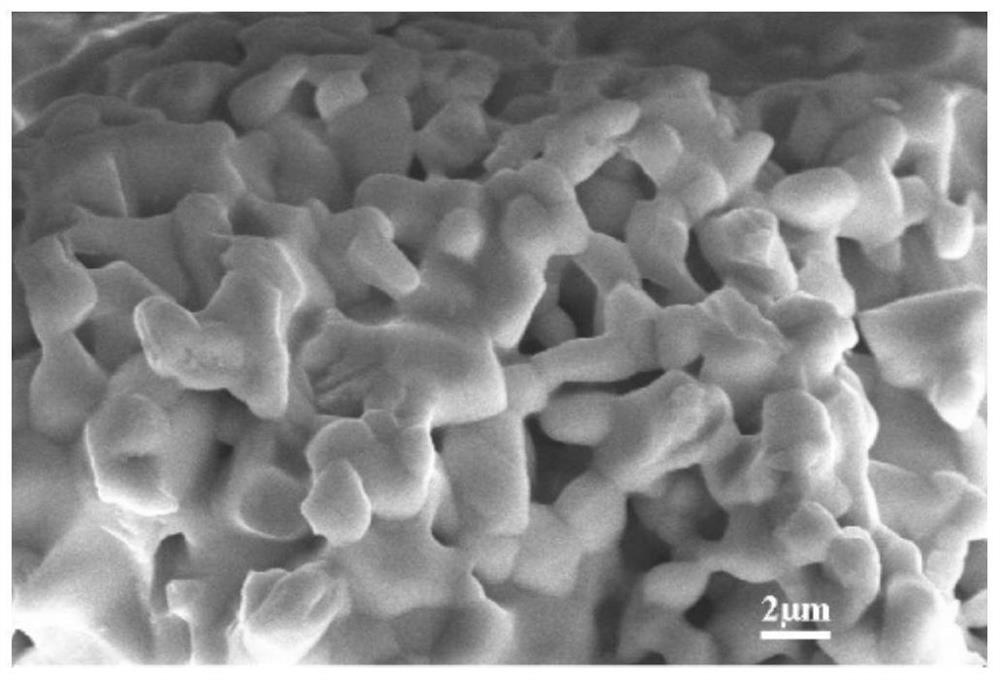

[0037] Based on the third generation nickel-based single crystal superalloy DD10, it is processed by wire cutting and grinding and polishing. Use sandpaper to polish the surface of the sample with a roughness of Ra≤1μm, and then use acetone and absolute alcohol to perform ultrasonic cleaning in order to remove stains on the experimental surface or fine corundum particles adhering to the surface and fully dry. The NiCoCrAlYTa bonding layer was prepared on the DD10 superalloy substrate by PS-PVD method, with a thickness of 100 μm. Then, a layer of columnar crystal YSZ ceramic thermal barrier layer with a thickness of 300 μm was prepared on the adhesive layer by PS-PVD method, and then a layer of (Gd 0.5 Tb 0.5 ) 4 al 2 o 9 (GdTbAM) anti-CMAS protective layer with a thickness of 100 μm and a porosity of 0.5%. Adopt Oerlikon Metco PS-PVD system, O3CP plasma spray gun, spraying distance is 1000mm, spray gun working power is 130kW, plasma gas is Ar-110slpm, He-20slpm, preheati...

Embodiment 3

[0040] Using the directionally solidified nickel-based superalloy DZ125 as the substrate, it is processed into a 30mm×30mm×3mm sample by wire cutting and grinding. The surface of the sample is sandblasted with 120 mesh corundum sand under compressed air, and then the sample is Put it in acetone and absolute alcohol for ultrasonic cleaning, fully remove the residual impurities and corundum fine sand on the surface of the sample, and then dry it; use supersonic flame spraying or low-pressure plasma spraying to prepare 120 μm thick NiCoCrAlYSi on the DZ125 alloy substrate Bonding layer, using atmospheric plasma spraying to prepare a 150 μm YSZ thermal barrier layer on the surface of the metal bonding layer, and then preparing a 250 μm thick new high-temperature thermal barrier ceramic coating on the surface of YSZ, the chemical composition is LaMgAl 11 o 19 、Gd 2 Zr 2 o 7 , (Gd 0.9 Yb 0.1 ) 2 Zr 2 o 7 , La 2 (Ce 0.3 Zr 0.7 ) 2 o 7 One of the materials (not limited to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com