Preparation method of magnesium-modified biochar-coated urea fertilizer

A technology of coating urea and biochar, which is applied in urea compound fertilizer, layered/coated fertilizer, magnesium fertilizer, etc., can solve the problems of low slow release performance and poor physical properties, and improve the slow release effect and performance. Improved, environmentally friendly performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of magnesium-modified biochar-coated urea fertilizer, comprising the following steps:

[0031] (1) The agricultural wastes are sequentially pulverized, sieved, carbonized and cracked to obtain biochar;

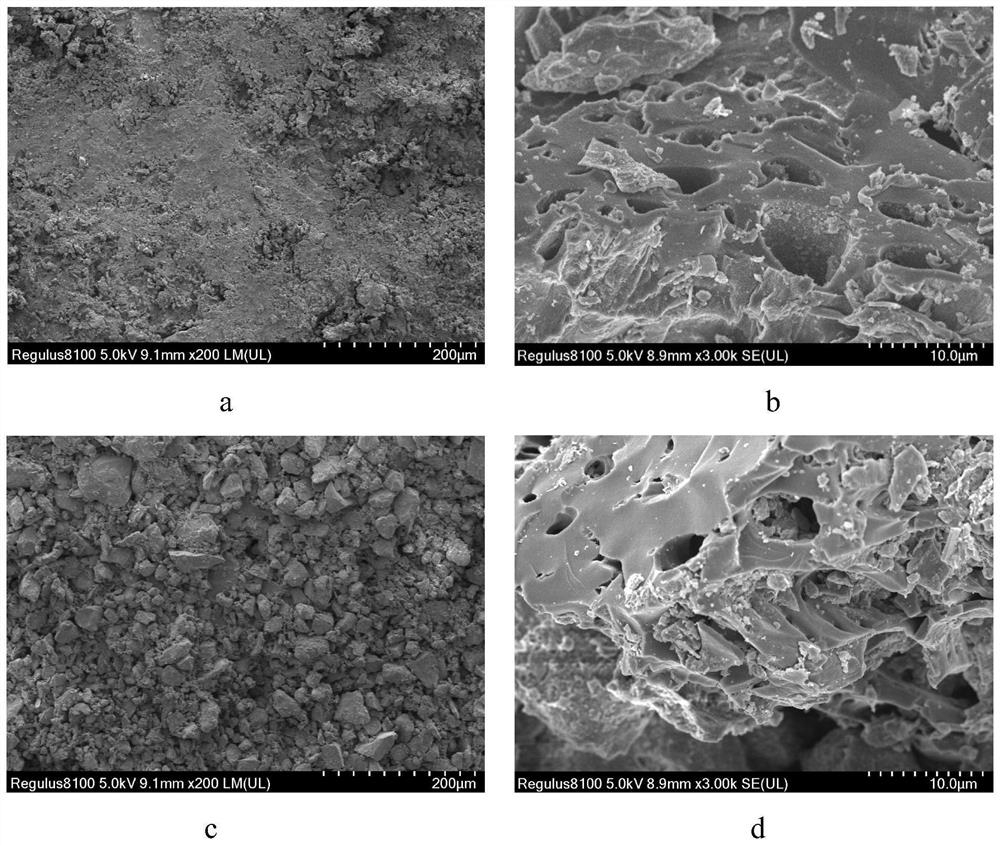

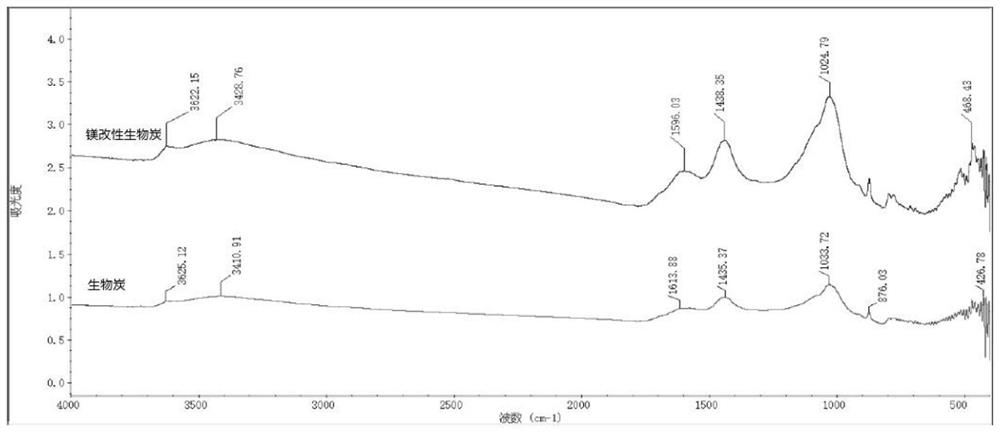

[0032] (2) Grinding the biochar to obtain biochar powder, then mixing with magnesium chloride solution, stirring, filtering, washing, and drying to obtain magnesium-modified biochar;

[0033] (3) Grinding the magnesium-modified biochar to obtain magnesium-modified biochar powder, and then mixing with polyvinyl alcohol solution, a plasticizer, and a catalyst to obtain a magnesium-modified biochar coating material;

[0034] (4) Coating the magnesium-modified biochar coating material and urea to obtain the magnesium-modified biochar-coated urea fertilizer.

[0035] In the invention, the agricultural wastes are sequentially crushed, sieved, and carbonized and cracked to obtain biochar.

[0036] In the present invention, ...

Embodiment 1

[0063] The preparation method of magnesium modified biochar coated urea fertilizer comprises the following steps:

[0064] (1) Preparation of biochar

[0065] The crop stalks were crushed sequentially, passed through a 5-mesh sieve, and carbonized and cracked for 2 hours at 500°C under anaerobic conditions to obtain biochar (abbreviated as P 1 B 1 );

[0066] (2) Preparation of magnesium-modified biochar

[0067] Grind the biochar through a 200-mesh sieve to obtain biochar powder, and mix the biochar powder with the prepared 0.01mol L -1 Magnesium Chloride (MgCl 2 ·6H 2 O) the solution is mixed according to 1:50 (m:V), the bottle mouth is sealed with a plastic wrap, and a magnetic stirrer is used to vigorously stir (1800r / min) for 3h, then filter, wash, and dry to obtain magnesium-modified biochar;

[0068] (3) Preparation of magnesium-modified biochar coating material

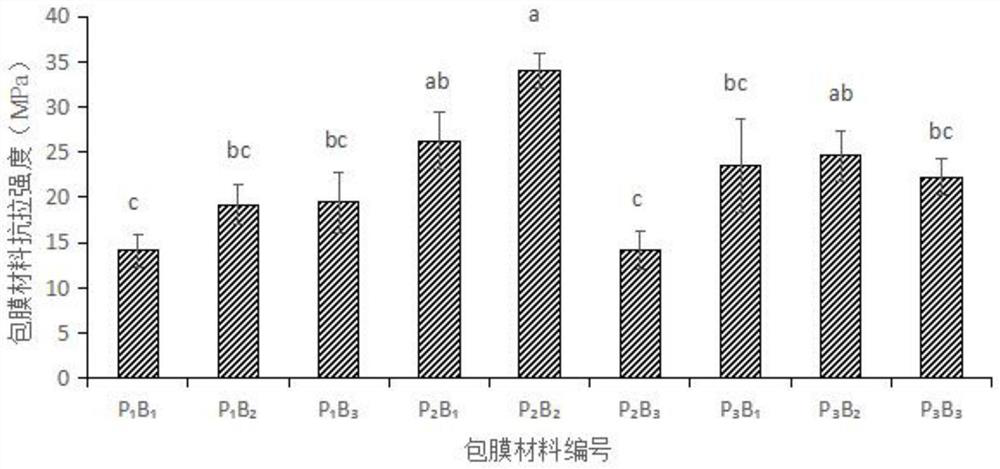

[0069] Grinding the magnesium-modified biochar through a 200-mesh sieve to obtain magnesium-modified...

Embodiment 2

[0081] According to embodiment 1 step (1), prepare magnesium modified biochar material 1 (abbreviated as P 1 B 2 ): adopt biochar 1.2g, polyvinyl alcohol (polymerization degree 1750, degree of alcoholysis 50%) 20g, glutaraldehyde 3.3mL, acetic acid 13.3mL and 1-octanol 0.2mL to prepare magnesium modified biological As for the carbon coated material, the magnesium modified biochar coated urea fertilizer is prepared according to the step (4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com