Method for comprehensively and efficiently treating zinc leaching residues

A technology of zinc leaching slag and leaching slag, which is applied in the field of comprehensive and efficient treatment of zinc leaching slag, can solve the problems of high cost of harmless treatment, waste of indium and copper resources, and inability to efficiently recycle, so as to save operating procedures and realize reduction Discharge, reduce the effect of process operation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

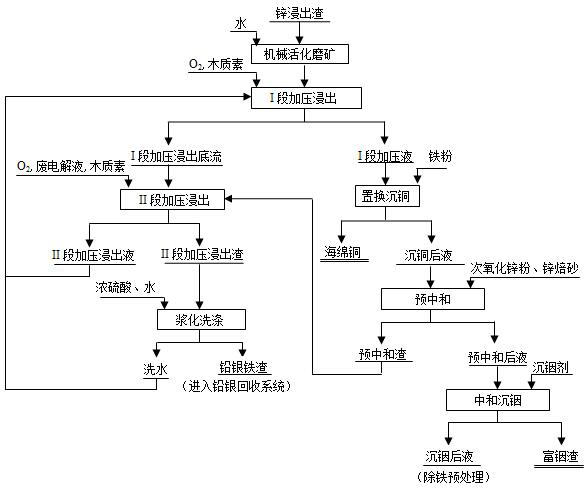

Image

Examples

Embodiment 1

[0066] An integrated method of leaching zinc hydrometallurgy efficient processing of slag, the specific steps are as follows:

[0067](1) The zinc hydrometallurgy leaching residue of an aqueous 10% (content of the main elements (dry basis): 22% zinc, 0.015% indium, 2.8% copper, 12% iron, 1% Pb, 0.04% Ag) It was activated mechanically grinding, to a particle size of 74μm finely ground material;

[0068] (2) Step (1) finely ground material output, fed from a feed pump lignin Stage I pressure within the reaction vessel, and heated by the plate heat exchanger deg.] C to 100 of Mixed acid leachate pressing section and the washing, the reaction temperature by the vapor in the tank is controlled to pass 180 ℃, the pressure was 1.6MPa, the reaction after 180min reaction slurry was allowed to stand in a layered thickener to give Stage I plus pressure leaching underflow and Stage I pressure leach solution (main ingredient: sulfuric acid concentration of 45 / L, an indium ion concentration ...

Embodiment 2

[0075] An integrated method of leaching zinc hydrometallurgy efficient processing of slag, the specific steps are as follows:

[0076] (1) The zinc hydrometallurgy leaching residue of an aqueous 15% (content of the main elements (dry basis): 17% zinc, 0.03% indium, 0.5% copper, 18% iron, 5% Pb, 0.03% Ag) was activated mechanically grinding, to give a particle size of 150μm finely ground material;

[0077] (2) The step (1) the output of finely ground material, lignin is fed by the feed pump Stage I pressure within the reaction vessel, and heated by the plate heat exchanger to 70 deg.] C of Mixed acid leachate pressing section and the washing with the vapor in the tank into the control reaction temperature was 110 deg.] C, the pressure was 0.3MPa, after 90min reaction slurry was allowed to stand in a layered thickener to give Stage I plus pressure leaching underflow and Stage I pressure leach solution (main ingredient: sulfuric acid concentration of 20g / L, an indium ion concentra...

Embodiment 3

[0084] An integrated method of leaching zinc hydrometallurgy efficient processing of slag, the specific steps are as follows:

[0085] (1) A 13% aqueous zinc hydrometallurgy leaching residue (content of the main elements (dry basis): 14% zinc, 0.05% indium, 4.0% copper, 22% iron, 3% of Pb, 0.02% Ag) It was activated mechanically grinding, to give a particle size of 55μm finely ground material;

[0086] (2) The step (1) the output of finely ground material, lignin is fed by the feed pump Stage I pressure within the reaction vessel, and heated by the plate heat exchanger to 90 deg.] C of Pressing the mixed acid segment leachate and the washing water, the temperature of the reaction with vapor in the tank is controlled to 160. fed deg.] C, the pressure was 1.0MPa, the reaction after 150min reaction slurry was allowed to stand in a layered thickener to give Stage I plus pressure leaching underflow and Stage I pressure leach solution (main ingredient: sulfuric acid concentration of 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com