Integrally formed three-dimensional metal net and production equipment thereof

A three-dimensional, production equipment technology, used in metal processing, coiled strips, electrical components, etc., can solve the problems of inability to do anti-corrosion treatment, complex production processes and equipment, easy to fall off, etc., to achieve rapid and uniform anti-corrosion treatment, enhanced Corrosion resistance, good synchronization matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

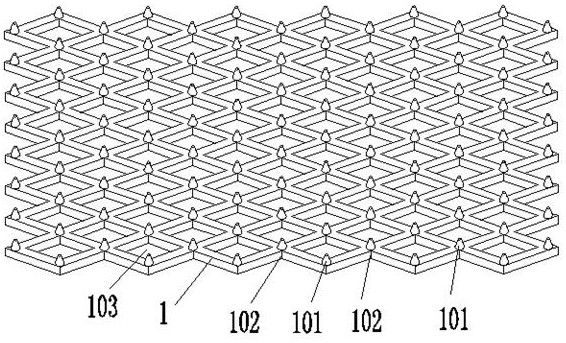

[0036] The present invention provides a three-dimensional structure metal mesh 1, the structure schematic diagram is as follows figure 1As shown, the X and Y directions of the metal mesh are formed by the arrangement and combination of diamond-shaped meshes of uniform size, one side in the Z-axis direction has Z-axis protrusions 101 at the intersection of the rhombus, and the other side has a flat surface. The material of the metal mesh can be any one of copper, aluminum, stainless steel and nickel.

[0037] The length of the metal mesh can be customized and processed according to requirements, the width range is 100mm-2000mm, and the thickness range is 0.05mm-1mm.

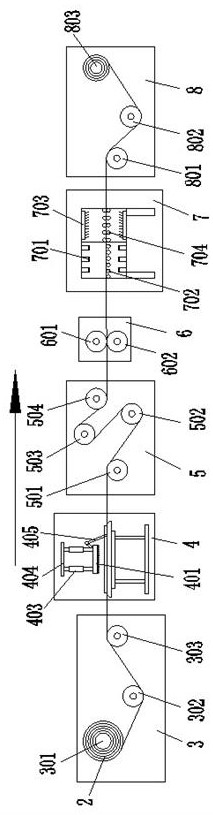

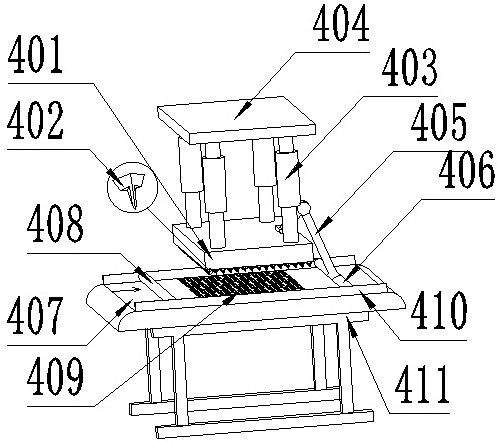

[0038] The present invention also provides an integrally formed production equipment for the above-mentioned metal mesh. The schematic diagram of the production and processing flow of the metal mesh is as follows: figure 2 As shown, it includes unwinding machine 03, hole cutting and stretching device 04 ( imag...

Embodiment 2

[0046] In Example 2, the production and processing flow of the metal mesh includes an unwinder 3, a hole-cutting and stretching device 4, a deviation correction device 5, a rolling device 6, and a winder 8 in sequence; the metal mesh anticorrosion treatment device 7 is arranged on another on the production line.

[0047] After the metal foil passes through the unwinding machine 3, the hole cutting and stretching device 4, the deviation correction device 5, the rolling device 6, and the winding machine 8, the device operation steps and method steps experienced are the same as those in Example 1, and what is obtained is no anti-corrosion Processed rolled metal mesh 1 .

[0048] Carry out separate anti-corrosion treatment to the metal mesh 1 in another assembly line, such as Figure 6 shown. It includes an unwinding machine 3, an anti-corrosion treatment device 7 and a winding machine 8 in sequence. The unwinding, winding and anti-corrosion treatment method steps are the same ...

Embodiment 3

[0050] In Example 3, the obtained finished metal mesh 1 is compounded with the composite material 9, and the cross-sectional schematic diagram is as follows Figure 7 shown.

[0051] The common method of compounding the metal mesh 1 and the composite material 9 is to lay the metal mesh on the corresponding mold, and lay the fiber cloth on the metal mesh. After demoulding, the metal mesh can be combined with the composite material. The metal mesh can be firmly bonded to the surface of the composite material to protect the composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com