Antiviral coating and preparation method thereof

An anti-virus and coating technology, applied in polyester coatings, anti-fouling/underwater coatings, polyurea/polyurethane coatings, etc., can solve the problems of ineffective utilization, long time required for anti-virus effect, etc., to achieve excellent anti-virus Active, improve antiviral activity, good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

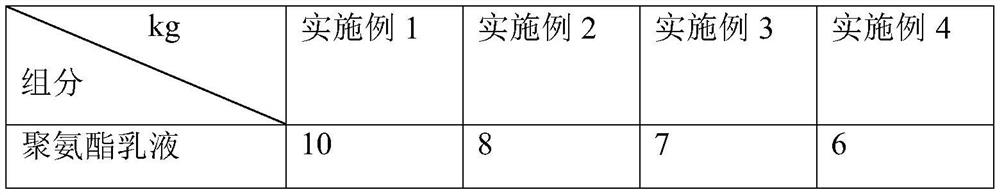

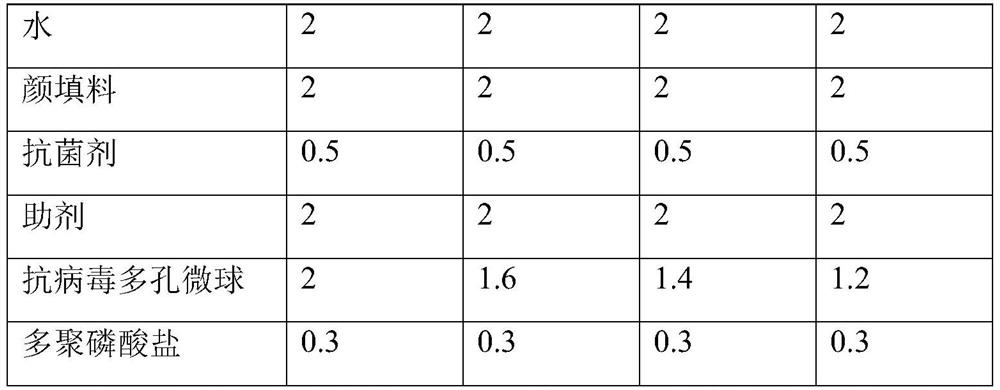

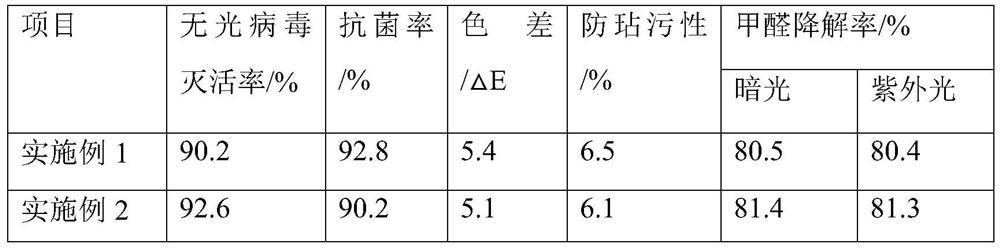

Examples

preparation example 1-9

[0050] In the preparation example, the polylactic acid is selected from Shanghai Fangcheng Plastic Raw Materials Co., Ltd., the brand is 7011; the patchouli oil is selected from Jiangxi Huabang Natural Fragrance Co., Ltd., and the model is Z08; the carbon nanotubes are selected from Shenzhen Teli New Material Technology Co., Ltd., Particle size is 2500 mesh; Zinc pyrithione is selected from Jinan Zhixuan Chemical Co., Ltd., and the model is kono;

preparation example 1

[0051] Preparation example 1: 1. 0.5 kg of activated carbon is added to 0.8 kg of Chinese medicine extract, ultrasonically impregnated, roasted, and ground to obtain Chinese medicine antiviral particles. Made of patchouli oil and emulsifier, the emulsifier is polysorbate-80, and the forsythia water extract is prepared by decocting forsythia and water at a mass ratio of 1:3 for 2 hours, then filtering and concentrating;

[0052] ② Dissolve 1 kg of polylactic acid in 10 kg of organic solvent, add the traditional Chinese medicine antiviral particles, emulsifier and porogen prepared in step ①, mix well to form a polymer emulsion, add hydrochloric acid, heat up to 80 ° C, stir for 3 hours, and obtain porous Microspheres, the mass ratio of emulsifier, porogen, acetic acid and polylactic acid is 1:1.5:1.5:1, the emulsifier polysorbate-80, and the porogen is sodium bicarbonate;

[0053] 3. Spray the antiviral mixed solution that comprises 0.5kg silica sol, 0.3kg carbon nanotubes and 0...

preparation example 2

[0054] Preparation example 2: 1. 1 kg of activated carbon is added to 1.2 kg of Chinese medicine extract, ultrasonically impregnated, roasted, and ground to obtain Chinese medicine antiviral particles. Made of patchouli oil and emulsifier, the emulsifier is polysorbate-80, and the forsythia water extract is prepared by decocting forsythia and water for 2 hours at a mass ratio of 1:3, then filtering and concentrating;

[0055] ②Dissolve 1.5kg of polylactic acid in 15kg of organic solvent, add the traditional Chinese medicine antiviral particles, emulsifier and porogen prepared in step ①, mix well to form a polymer emulsion, add hydrochloric acid, heat up to 90°C, stir for 5h, and get Porous microspheres, the mass ratio of emulsifier, porogen, hydrochloric acid and polylactic acid is 1.5:2:2:1, and the emulsifier is polysorbate-80;

[0056] 3. Spray the antiviral mixed solution that comprises 0.8kg silica sol, 0.7kg carbon nanotubes and 0.5kg zinc pyrithione through ultrasound t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com