Preparation method of polyphenol iron oxide adsorption material for heavy metal wastewater treatment

A technology for wastewater treatment and adsorption materials, applied in the directions of alkali metal oxides/hydroxides, alkali metal compounds, water/sewage treatment, etc., can solve the problems of long adsorption equilibrium time, complex synthesis process, low adsorption performance, etc. The effect of short time-consuming, simple synthesis steps and high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 10 mL of 100 mg / mL ellagic acid solution to a 25 mL centrifuge tube, then add 2 mL of 20 mg / mL FeCl to the ellagic acid solution 3 ·6H 2 O solution, adjust the pH to 7.2 with NaOH solution, shake and mix evenly in a shaker, let it stand for 1h, centrifuge and wash it, then add 10mL 0.1mol / L NaOH solution to it and stir for 2h, wash until neutral and dry The polyphenol iron oxide adsorption material for heavy metal wastewater treatment can be obtained.

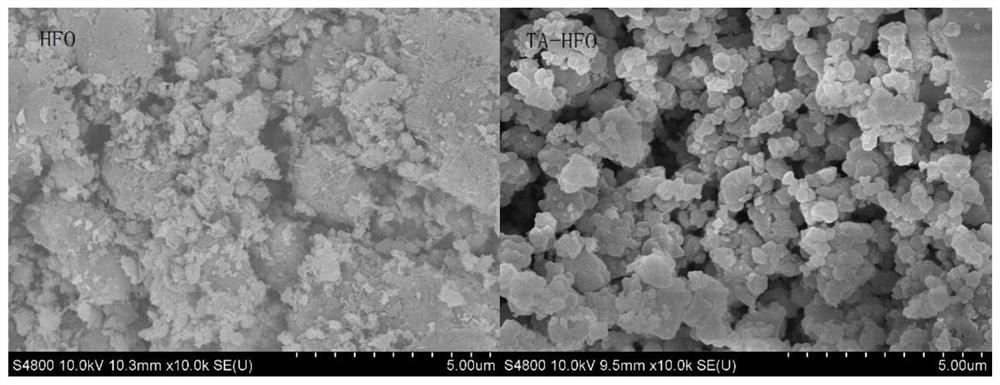

[0027] Such as figure 1 As shown, using the polyphenol-iron oxide adsorbent material prepared in this embodiment, the scanning electron microscope of the material was observed. Compared with the HFO material, it was observed that the material was more dispersed, and the adsorbent material had excellent dispersion performance.

Embodiment 2

[0029] In a 25mL centrifuge tube, add 8mL of 50mg / mL tannic acid solution, and then add 0.864mL of 40mg / mL Fe(NO 3 ) 3 solution, with NaHCO 3 Adjust the pH of the solution to 7.2, vortex and mix evenly, centrifuge and wash, then add 10mL 0.1mol / L NaOH solution and stir for 1.5h, wash until neutral and freeze-dried to obtain polyphenolic iron oxide adsorption for heavy metal wastewater treatment Material.

[0030] The polyphenol-iron oxide adsorbent material prepared by this embodiment can be synthesized within 3 hours at room temperature, the operation is simple, the source of raw materials is wide, safe and environmentally friendly, and the adsorption capacity reaches 340 mg / g.

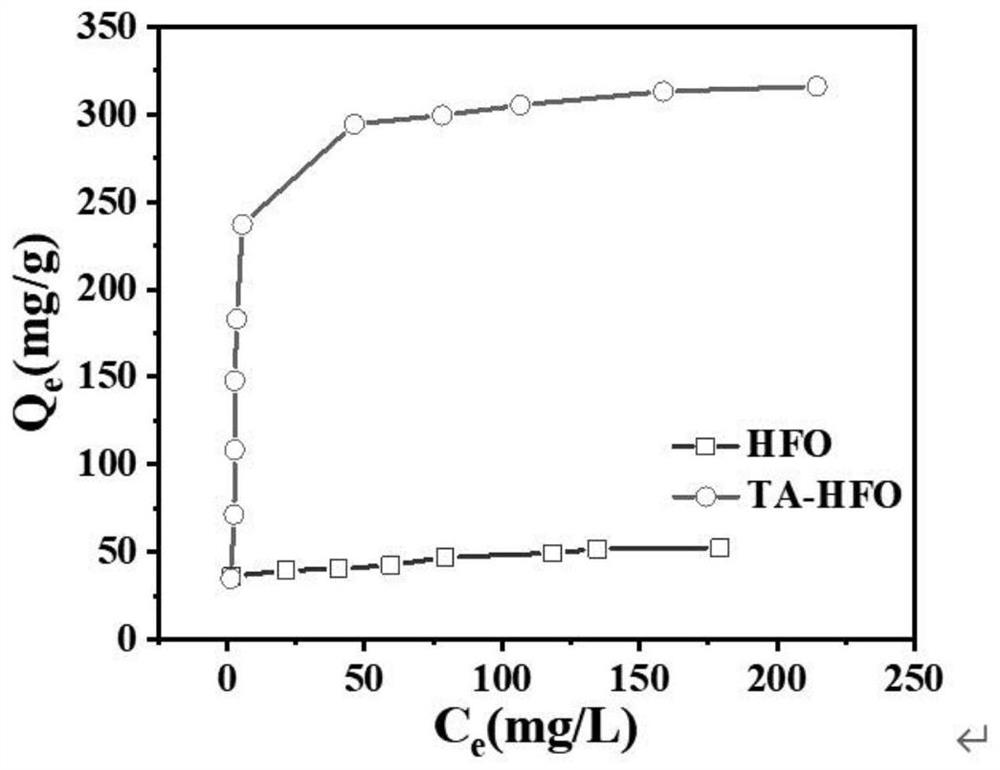

[0031] Using the polyphenol-iron oxide adsorbent material prepared in this embodiment, the adsorption isotherm experiment was carried out, and 0.025g of the material was weighed in a 250mL conical flask, and 50mL of Pb with different concentrations were added 2+ Put the solution into a shaker for ...

Embodiment 3

[0034] Add 20mL of 50mg / mL gallic acid solution to a 25mL centrifuge tube, and then add 4mL of 80mg / mL FeCl to the gallic acid solution 3 solution, adjust the pH to 7.2 with KOH solution, shake on a shaking table for 1 hour, centrifuge and wash it, then add 10 mL of 0.2 mol / L NaOH solution and stir for 3 hours, wash until neutral and freeze-dried to obtain heavy metal wastewater treatment. Phenolic iron oxide adsorption material.

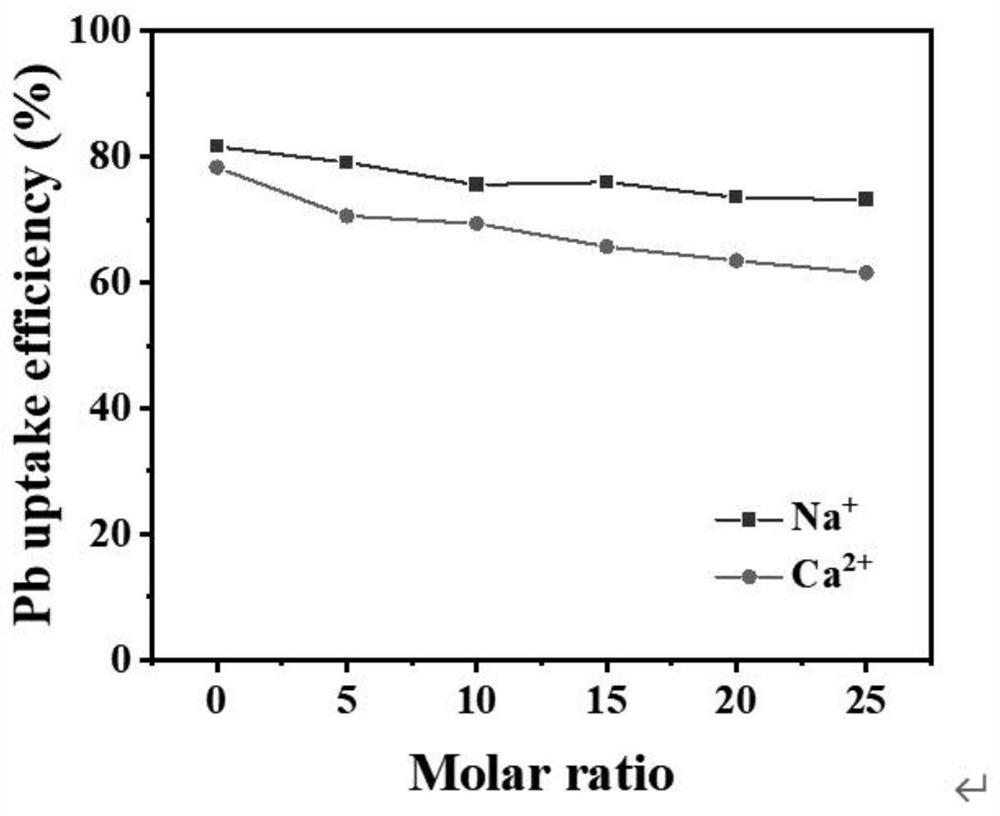

[0035] The polyphenol-iron oxide adsorbent material prepared by this embodiment can be synthesized at normal temperature, with simple operation, wide sources of raw materials, safety and environmental protection, and has specific adsorption for heavy metals in the presence of competing ions.

[0036] Using the polyphenol-iron oxide adsorbent material prepared in this embodiment, a competitive ion experiment was carried out, and 0.025g of the material was weighed in a 250mL Erlenmeyer flask, and 50mL of 200mg / L Pb was added respectively. 2+ solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com