Efficient low-consumption catalytic oxidation water treatment method

A catalytic oxidation and water treatment technology, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve problems such as difficulty in light source intensity, reaction efficiency and energy consumption limitations, and achieve the goal of improving treatment conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] P-BiO 1-x Br preparation: using industrially produced BiOBr as a raw material, sodium hypophosphite is selected as a phosphorus source, a porcelain boat containing 2g of phosphorus source is placed in the upwind direction of the tube furnace, and the porcelain boat with BiOBr (1g) is placed Downwind, N 2 As a carrier gas, the heating rate is 2°C / min, the reaction temperature is 450°C, and the reaction time is 2h. Cool down to room temperature naturally after the reaction, take out the P-BiO that is located in the downwind direction 1-x Porcelain boat of Br, dispersed by deionization, ultrasonication for 10min, suction filtration, repeated washing with deionized water for 3 times, drying at 60°C to obtain P-BiO 1-x Br catalyst.

Embodiment 2

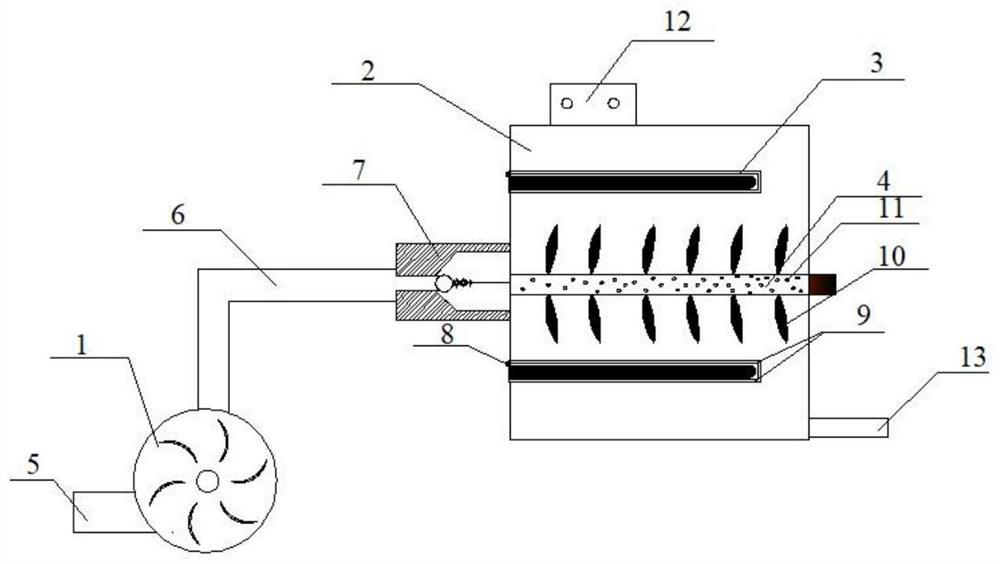

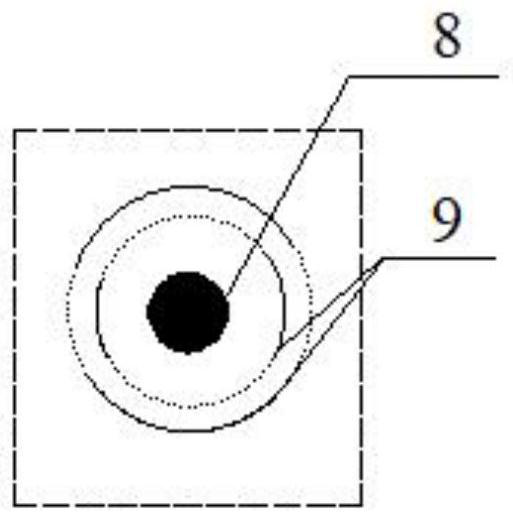

[0039] The construction of the reaction apparatus: as figure 1 and figure 2 As shown, it includes water inlet quantitative pump 1, cylindrical light reaction box 2, light source system with adjustable slit 3, stirring and feeding hole column 4, water inlet 5, water inlet pipe 6, self-sealing plug 7, ultraviolet Lamp 8, lampshade 9, stirring impeller 10, feeding port 11, power supply 12, water outlet 13; the water inlet quantitative pump can control the water intake of the reaction tank on-line, when the waste water flows from the water inlet through the quantitative pump, it passes through the water inlet pipe freely The plugging head enters the reaction box, and the ultraviolet lamp inside the box can adjust the light intensity according to the rotatable lampshade on the outer layer during the water treatment reaction. The water stirring inside the reaction box adopts a stirring and feeding hole in the middle of the box. When the power is turned on and the reaction starts, ...

Embodiment 3

[0047] With the P-BiO prepared in Example 1 1-x Br photocatalyst is used for the degradation test of 50mg / L norfloxacin simulated waste water, and catalyst concentration is 0.2g / L, and reaction time is 1h, and reaction temperature is room temperature, and catalyst is added in the reactor constructed in embodiment 2, adds Simulated wastewater, after the reaction, the removal rate of norfloxacin was 100%, the removal rate of TOC was 60%, and the defluorination rate was 60%. Moreover, the catalyst has been subjected to repeated degradation tests for 24 hours, and its catalytic performance is stable without significant attenuation.

[0048] The degradation test was carried out with the waste water containing a large amount of drugs and their intermediates discharged from the pharmaceutical factory as the target pollutant. The removal rate of TOC was 50-60%, and after 24 hours of continuous reaction, the performance of the catalyst had no obvious attenuation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com