Modified polypropylene material as well as preparation method and application thereof

A polypropylene material and polypropylene technology, applied in the field of modified polypropylene material and its preparation, can solve the problems of light waste, reduce the light source utilization rate of lamps, and light leakage of lamp shells, so as to improve the gloss and improve the light source utilization of lamps rate, the effect of fine crystal size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

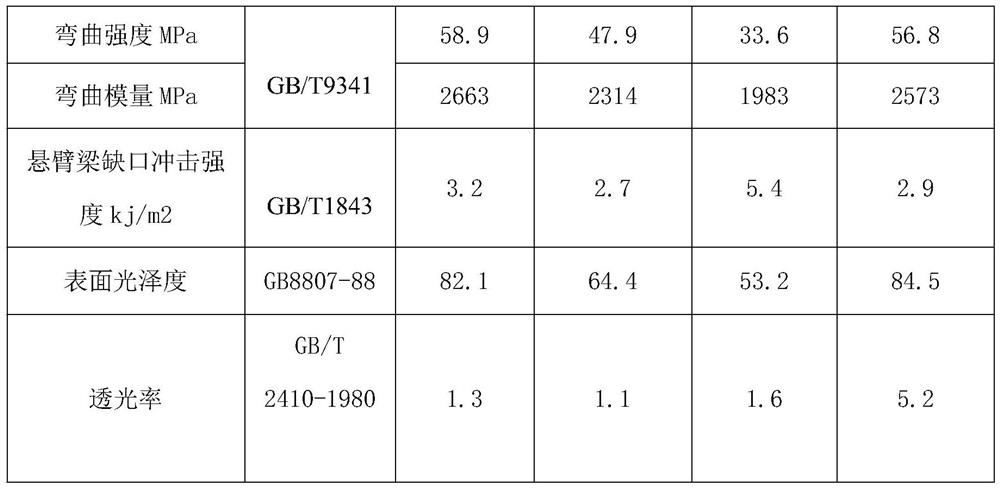

Examples

Embodiment 1

[0036] Raw material components and components: high crystalline polypropylene 66g, titanium white powder 15g, compativity 4g, nano-grade sulfate 15g, lubricant (calcium hard esteric) 0.2g, lubricant (polyethylene wax) 0.3g Antioxidant (four [β- (3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester) 0.3 g, silane coupling agent (vinyl triethoxysilane) 0.15 g.

[0037] The specific preparation method includes the following steps:

[0038] (1) Take 15 g of dry nanoscale barium sulfate, stirring with a liquid solution of a 1.0.15 g of a silane coupling agent for 30 min, here, the mass concentration of ethanol in ethanol solution is 10%, volume is 5 ml, room temperature was allowed to stand for 12 h, vacuum filtration, placed in an electric heated hemond dry box at 80 ° C to constant weight, and the surface treated nano sulfate is prepared;

[0039] (2) Take 66 g of high-crystalline polypropylene, (1), nano-stage sulfate, 4G compatibilizer, 15g titanium white powder...

Embodiment 2

[0042] Raw material components and components: high crystalline polypropylene 55g, titanium powder 5g, compatible agent 3g, nano-stage sulfate 15g, lubricant (calcium hard esteric acid) 0.2g, lubricant (polyethylene wax) 0.3g Antioxidant (four [β- (3,5-di-tert-butyl-4-hydroxyphenyl) 0.2 g, silane coupling agent (vinyl triethoxysilane) 0.1 g.

[0043] The specific preparation method includes the following steps:

[0044] (1) According to the ratio, 15 g of dry nano-stage sulfate, the ethanol solution of 0.1 g of the silane coupling agent is stirred at a low speed of 30 min, here, the mass concentration of ethanol in ethanol solution is 10%, volume is 5 ml, room temperature was allowed to stand for 12 h, vacuum filtration, placed in an electric heated hemond dry box at 80 ° C to constant weight, and the surface treated nano sulfate is prepared;

[0045](2) Take 77 g of high-crystalline polypropylene, nano-grade sulfate, 3G compatible agent, 5 g of titanium white powder, 0.2 g of ant...

Embodiment 3

[0048] Raw material components and components content: high crystalline polypropylene 77g, titanium powder 15g, compativity 5g, nano-grade sulfate 30g, lubricant (calcium hard ester) 0.5 g, lubricant (polyethylene wax) 0.5g Antioxidant (four [β- (3,5-di-tert-butyl-4-hydroxyphenyl) 1 g, silane coupling agent (vinyl triethoxysilane) 0.3 g.

[0049] The specific preparation method includes the following steps:

[0050] (1) It is highly stirred by a 25 g of dry nano-stage sulfate, and the ethanol solution of 0.3 g of silane coupling agent is stirred at a low speed of 30 min, here, the mass concentration of ethanol in ethanol solution is 10%, volume is 5 ml, room temperature was allowed to stand for 12 h, vacuum filtration, placed in an electric heated hemond dry box at 80 ° C to constant weight, and the surface treated nano sulfate is prepared;

[0051] (2) Take 77 g of high-crystalline polypropylene, (1), nano-stage sulfate, 5g compatible agent, 15g titanium powder, 1 g of antioxidan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com