Bactericidal diol chain extender, preparation method thereof and application of bactericidal diol chain extender in multifunctional synergistic anti-fouling waterborne polyurethane

A diol chain extender and bactericidal technology, which can be used in biocide-containing paints, antifouling/underwater coatings, polyurea/polyurethane coatings, etc. It can solve the problems of antifouling failure, fouling adhesion and proliferation, etc. Achieve the effects of reducing pollution, saving energy, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment provides a bactericidal diol chain extender, using dibromooctyl glycol and 1,2-benzisothiazol-3-one (BIT) for chemical reaction in a microwave reactor respectively, the specific process is as follows.

[0070] Add dibromooctyl glycol and 1,2-benzisothiazol-3-one (BIT) into the reaction flask at a molar ratio of 1.2:2.4, add methanol to dissolve, put it in a microwave reactor, and then heat to 52°C After constant temperature reaction for 12 hours, the resulting product was extracted with ethyl acetate, then dried with anhydrous magnesium sulfate, filtered and rotary evaporated to remove ethyl acetate, and then dried overnight at 45°C under vacuum to obtain a bactericidal diol chain extender, It is a nonionic antimicrobial diol chain extender.

Embodiment 2~6

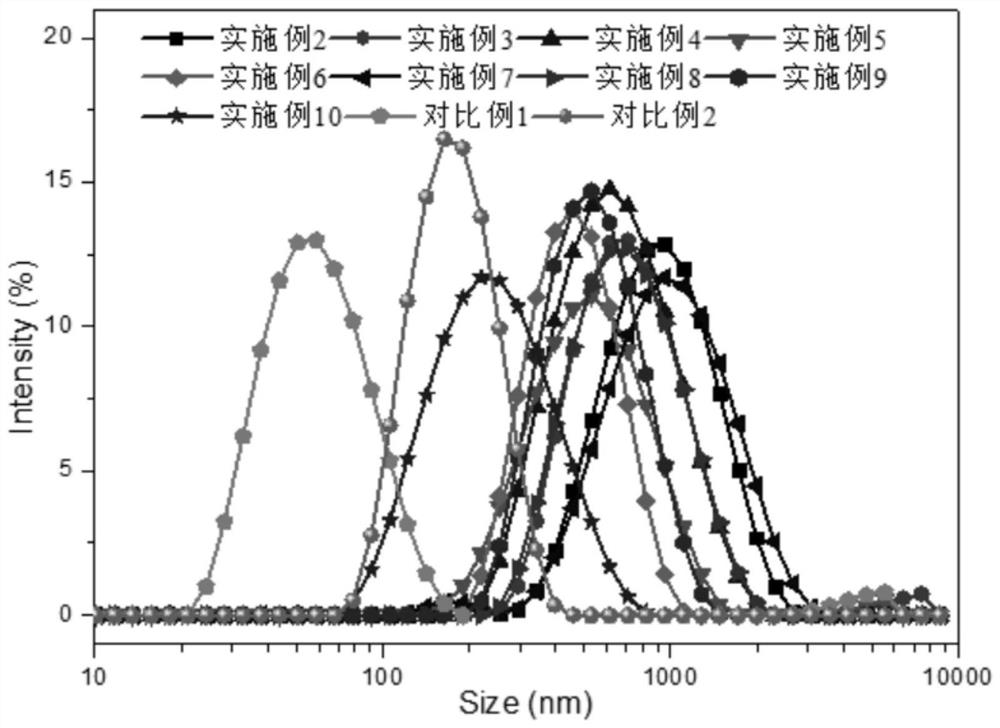

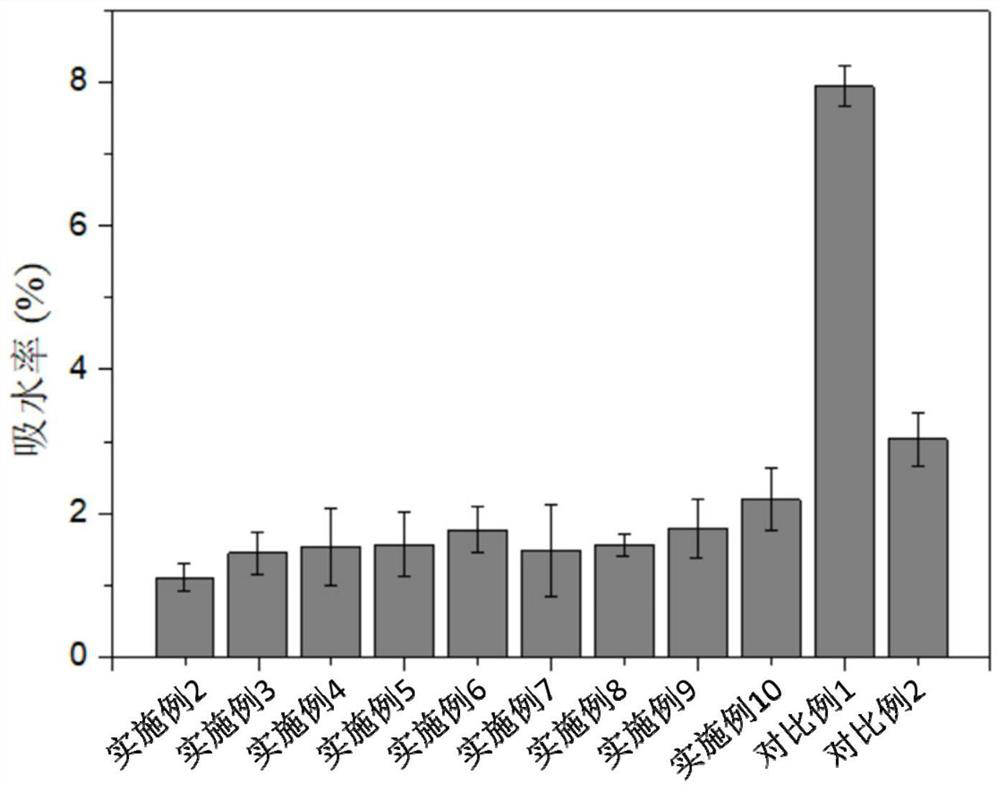

[0072] Example 2-2 provides a series of cationic multifunctional synergistic anti-pollution polyurethane prepared by using the diol chain extender prepared in Example 1.

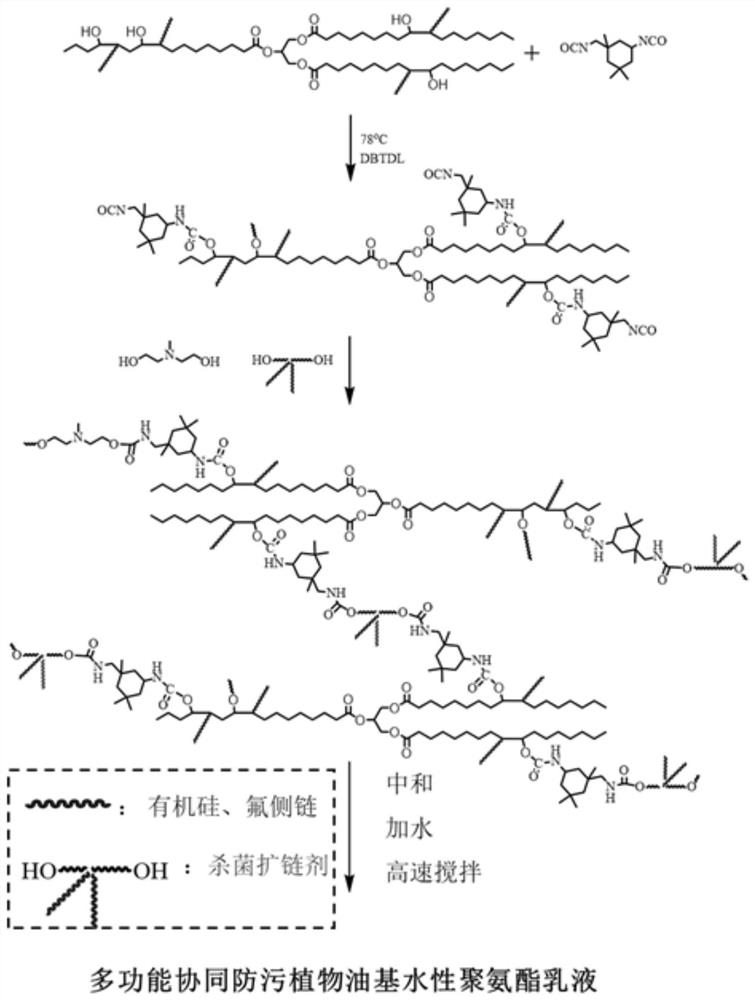

[0073] Specifically, the aqueous polyurethane emulsion was prepared by the following steps: respectively adding polyols I and II and diisocyanate into a double-neck flask equipped with mechanical stirring, and stirring and mixing at a temperature of 75° C. for 15 minutes (reaction stage 1). Then, add catalyst (2.5% mass fraction of reactant) and embodiment 1 obtained chain extender and MDEA to continue to react for 22 minutes (reaction stage 2). Subsequently, methyl ethyl ketone (MEK) with a solid content of 32% was added to reduce the viscosity of the system and the reaction was continued for 22 minutes. Then, when the temperature was cooled to room temperature, the system was neutralized with acetic acid for about 15 minutes. Finally, the mixture was emulsified with distilled water at 222 rpm for 22 minut...

Embodiment 7~8

[0084] Embodiments 7-8 provide a series of anionic multifunctional synergistic anti-pollution polyurethanes prepared by Embodiment 1

[0085] Specifically, the aqueous polyurethane emulsion was prepared by the following steps: respectively adding polyols I and II and TDI into a double-necked flask equipped with mechanical stirring, and stirring and mixing at a temperature of 22° C. for 32 minutes (reaction stage 1). Then, add the catalyst (2.5% mass fraction of the reactant) and the chain extender obtained in Example 1 and DMPA to continue the reaction for 15-32 minutes (reaction stage 2). Subsequently, methyl ethyl ketone (MEK) with a solid content of 32% was added to reduce the viscosity of the system and the reaction was continued for 22 minutes. Then, when the temperature was cooled to room temperature, the system was neutralized with triethylamine for about 22 minutes. Finally, the mixture was emulsified with distilled water at 422 rpm for 122 minutes (emulsification tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com