Preparation method of layered carbon-doped sodium ferric phosphate positive electrode material

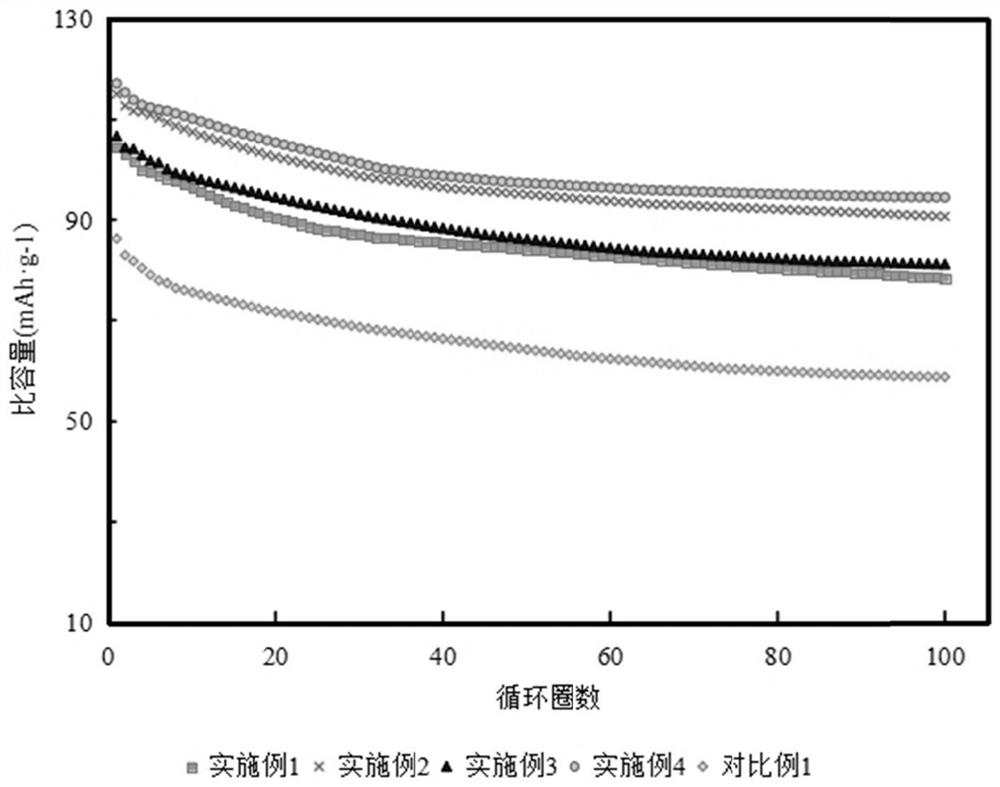

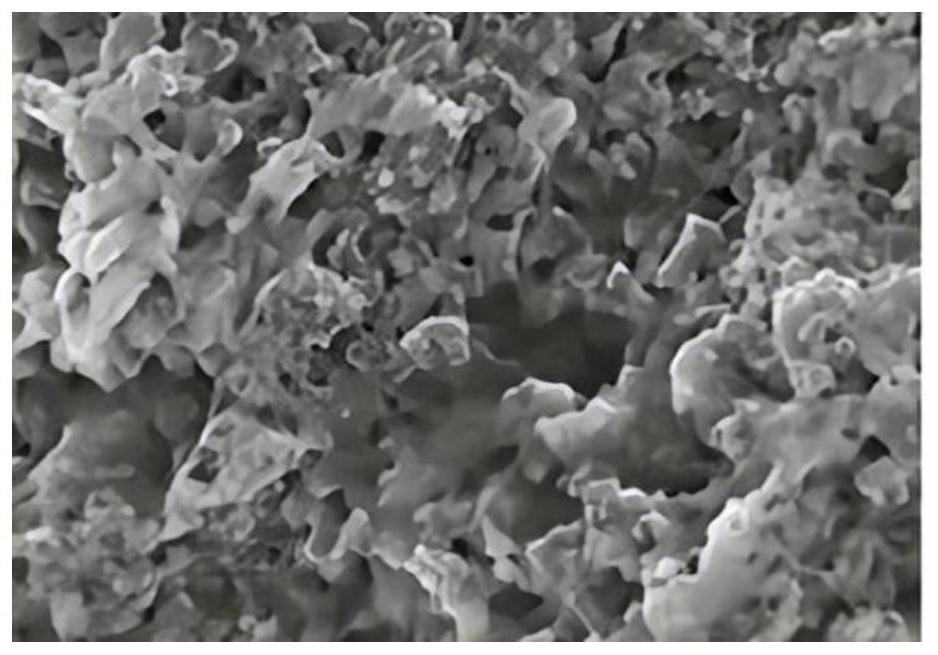

A technology of sodium iron phosphate and positive electrode materials, which is applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of low specific capacity, poor cycle performance and discharge rate performance of sodium-ion batteries, and achieve improved discharge specific capacity, Enhanced cycle stability and short diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

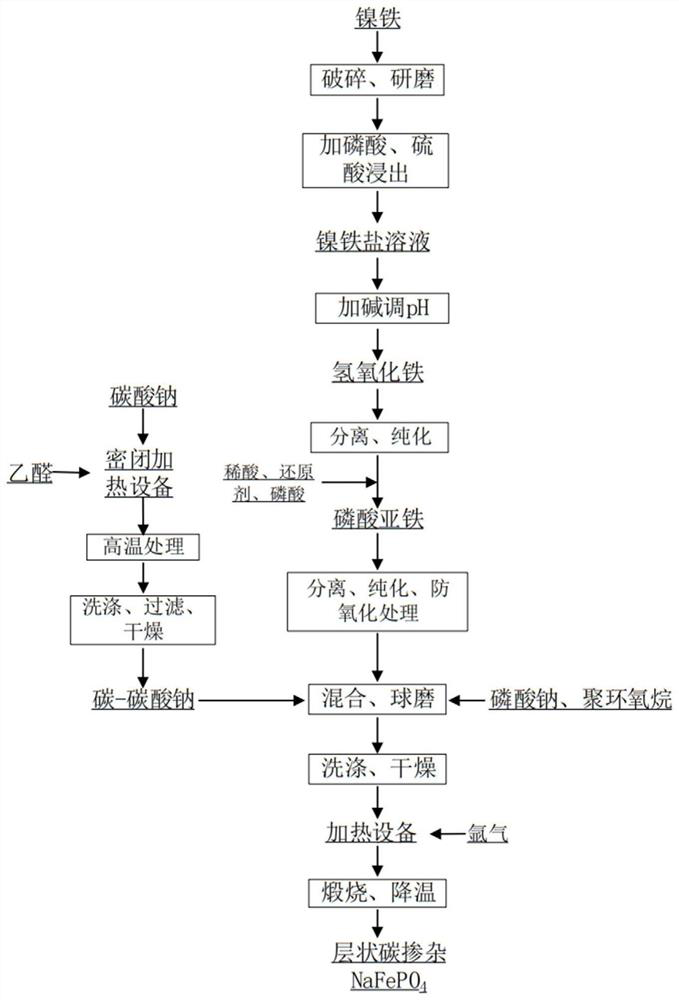

[0037] In this example, a layered carbon-doped sodium iron phosphate positive electrode material is prepared, and the specific process is as follows:

[0038](1) Ferronickel is crushed and ground into ferronickel powder, and mixed acid (the volume ratio of phosphoric acid and sulfuric acid is 30:30, H + About 14.5mol / L) leaching, the solid-liquid ratio of nickel-iron powder and mixed acid is 1:8.5g / ml, the leaching solution is nickel-iron salt solution, add 0.050mol / L sodium hydroxide to adjust pH=2.4 to obtain iron hydroxide precipitation, add Purify and remove impurities with dilute alkali to obtain ferric hydroxide, separate and dry for storage;

[0039] (2) Dissolve 3.83mol ferric hydroxide and 7.1L 0.30mol / L sulfuric acid, add 8.4mol iron powder and stir for reduction, then add 3.5L 1.21mol / L phosphoric acid to obtain ferrous phosphate precipitation, separate, purify, dry, anti-oxidation;

[0040] (3) Put 160g of superfine sodium carbonate powder in a high-temperature-r...

Embodiment 2

[0044] In this example, a layered carbon-doped sodium iron phosphate positive electrode material is prepared, and the specific process is as follows:

[0045] (1) Ferronickel is crushed and ground into ferronickel powder, and mixed acid (the volume ratio of phosphoric acid and sulfuric acid is 30:45, H + About 16.5mol / L) leaching, the solid-liquid ratio of nickel-iron powder and mixed acid is 1:8.8g / ml, the leaching solution is nickel-iron salt solution, add 0.20mol / L sodium hydroxide to adjust pH=2.7, pH=7.9 to obtain hydrogen respectively Precipitate iron oxide and nickel hydroxide, add dilute alkali to purify and remove impurities respectively, and obtain iron hydroxide and nickel hydroxide, which are stored in a dry place.

[0046] (2) Dissolve 4.73mol of ferric hydroxide and 6.7L of 0.60mol / L sulfuric acid, add 9.50mol of iron powder and stir for reduction, then add 3.5L of 1.0mol / L phosphoric acid to obtain ferrous phosphate precipitation, separate, purify, dry, anti-ox...

Embodiment 3

[0050] In this example, a layered carbon-doped sodium iron phosphate positive electrode material is prepared, and the specific process is as follows:

[0051] (1) Ferronickel is crushed and ground into ferronickel powder, and mixed acid (the volume ratio of phosphoric acid and sulfuric acid is 30:30, H + About 14.5mol / L) leaching, the solid-liquid ratio of nickel-iron powder and mixed acid is 1:10.0g / ml, the leaching solution is nickel-iron salt solution, add 0.050mol / L sodium hydroxide to adjust pH=2.6 to obtain iron hydroxide precipitation, add Purify and remove impurities with dilute alkali to obtain ferric hydroxide, separate and dry for storage;

[0052] (2) Dissolve 3.96mol ferric hydroxide and 4.5L 0.50mol / L sulfuric acid, add 8.4mol iron powder and stir for reduction, then add 3.5L 1.21mol / L phosphoric acid to obtain ferrous phosphate precipitation, separate, purify, dry, anti-oxidation;

[0053] (3) Put 140g of ultra-fine sodium carbonate powder in a high-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com