Non-aqueous electrolyte and non-aqueous electrolyte battery using same

A non-aqueous electrolyte and battery technology, used in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems such as poor kinetic stability, increased chemical reaction rate, and reduced battery cycle charge and discharge capacity. , to achieve the effect of enhanced oxidation resistance, easy reduction, improved cycle performance and high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-16

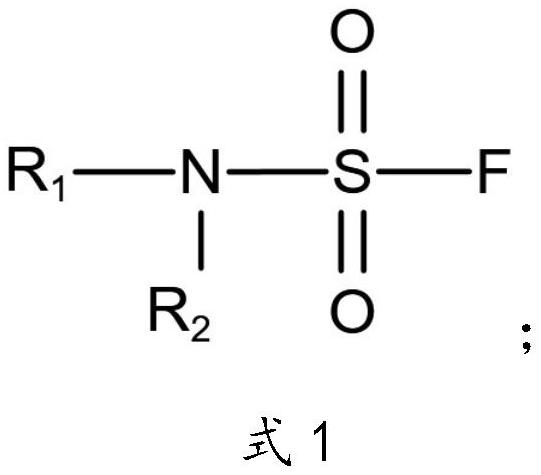

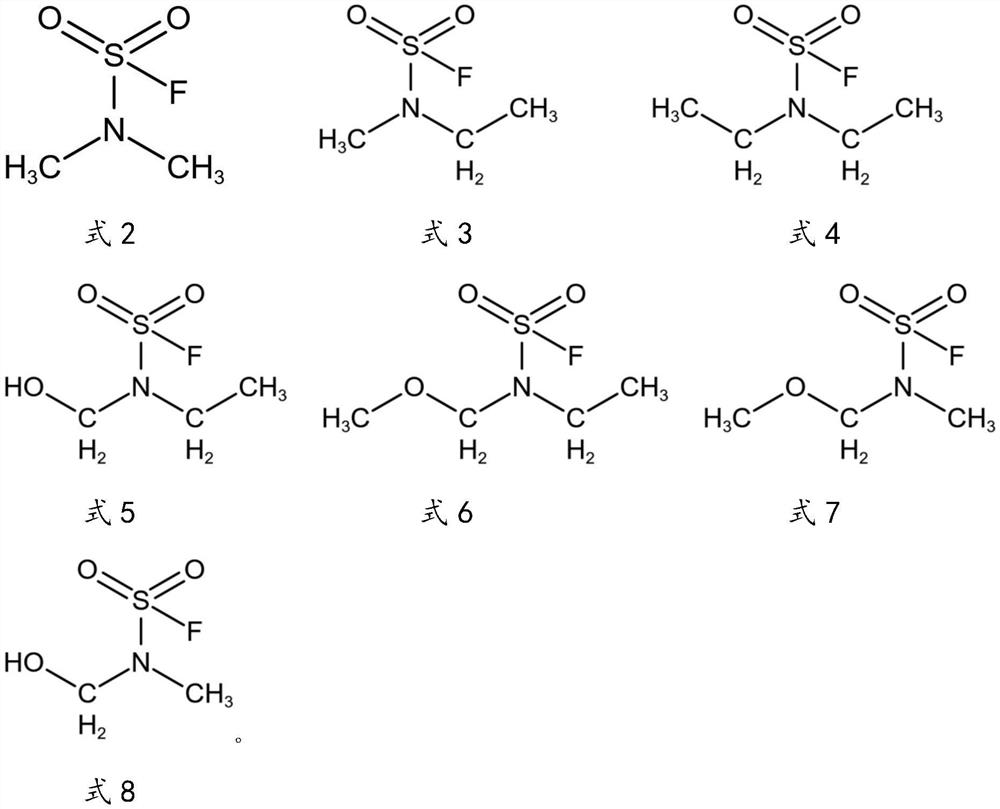

[0035] A non-aqueous electrolyte battery, the positive electrode is LiFePO 4 , the negative electrode is artificial graphite, the diaphragm is a microporous polyethylene film, and the electrolyte used is in the range of EC (ethylene carbonate): EMC (ethyl methyl carbonate): DMC (dimethyl carbonate) = 1:1:1 (volume ratio ) dissolved LiPF in the mixed solvent 6 Make a 1mol / L solution, and add the corresponding mass concentration of LiPO 2 f 2 , special lithium salt LiODFB (lithium difluorooxalate borate) and compounds, the compound structure formula is as follows:

[0036]

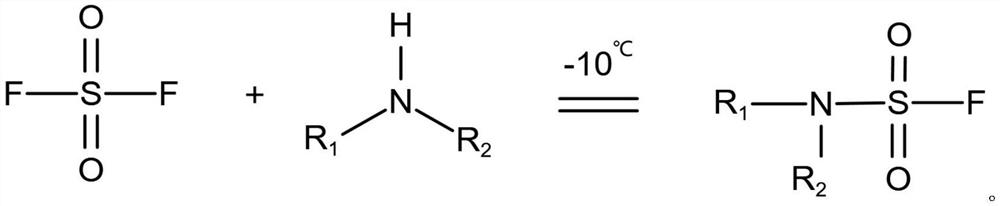

[0037] The synthetic route of compound is as follows:

[0038]

[0039] According to the above method, the prepared electrolyte and the associated positive and negative electrodes, diaphragm, etc. are made into the non-aqueous cylindrical 18650 battery of the embodiment in Table 1 below:

[0040] Table 1

[0041]

[0042]

[0043] The battery that the embodiment of the present invention and ...

Embodiment 17

[0061] A kind of non-aqueous electrolyte battery, positive pole LiNi x co y mn z L (1-x-y-z) o 2 , where L is one of Co, Al, Sr, Mg, Ti, Ca, Zr, Zn, Si, Fe, specifically: LiNi 0.33 co 0.33 mn 0.33 0 2 , LiNi 0.4 co 0.2 mn 0.4 0 2 , LiNi 0.4 co 0.3 mn 0.3 0 2 , LiNi 0.5 co 0.2 mn 0.3 0 2 , LiNi 0.6 co 0.2 mn 0.2 0 2 , LiNi 0.8 co 0.1 mn 0.1 0 2 , LiNi 0.9 co 0.05 mn 0.05 0 2 , LiNi 0.33 co 0.33 mn 0.27 al 0.06 0 2 , LiNi 0.6 co 0.17 mn 0.2 Mg 0.03 0 2 , LiNi 0.305 co 0.33 mn 0.33 Ti 0.025 0 2 , LiNi 0.33 co 0.305 mn 0.33 Ti 0.025 0 2 , LiNi 0.33 co 0.33 mn 0.305 Ti 0.025 0 2 , LiNi 0.784 co 0.1 mn 0.1 Ca 0.016 0 2 , LiNi 0.768 co 0.1 mn 0.1 Ca 0.03202 , LiNi 0.736 co 0.1 mn 0.1 Ca 0.064 0 2 , LiNi 0.5 co 0.2 mn 0.29 Zr 0.01 0 2 , LiNi 0.333 co 0.292 mn 0.333 Zn 0.041 0 2 , LiNi 0.333 co 0.25 mn 0.333 Zn 0.083 0 2 , LiNi 0.333 co 0.166 mn 0.333 Zn 0.167 0 2 , LiNi 0.333 co 0.3 mn 0.333 Fe ...

Embodiment 18

[0064] A kind of non-aqueous electrolyte battery, positive pole LiNi x co y mn z L (1-x-y-z) o 2 , where L is at least one of Co, Al, Sr, Mg, Ti, Ca, Zr, Zn, Si, Fe; 0≤x≤1, 0≤y≤1, 0≤z ≤1, 06 Make a 1mol / L solution, and add the corresponding mass concentration of LiPO 2 f 2 , special lithium salt LiBF4 (lithium tetrafluoroborate) and compounds, the compound structural formula is as follows:

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com