Inorganic filler high-flux hydroxylation method and device based on low-temperature plasma

A low-temperature plasma and plasma technology, applied in inorganic pigment processing, chemical instruments and methods, fibrous fillers, etc., can solve problems such as bulky supporting devices, achieve good compatibility, low processing cost, and improve thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] see Figure 1 to Figure 6 , a low-temperature plasma-based high-throughput hydroxylation method for inorganic fillers, comprising the following steps:

[0046] 1) Spread the boron nitride powder 3 to be processed on the conveyor belt 1 . The material of the conveyor belt 1 includes polyimide.

[0047] The average particle diameter of the boron nitride powder 3 is 1 μm˜5 μm.

[0048] 2) The roller-to-roller device is used to drive the conveyor belt 1 to move, so that the flat boron nitride powder 3 passes through the plasma region.

[0049] The roll-to-roll device includes several rollers for driving the polyimide conveyor belt 1 to move.

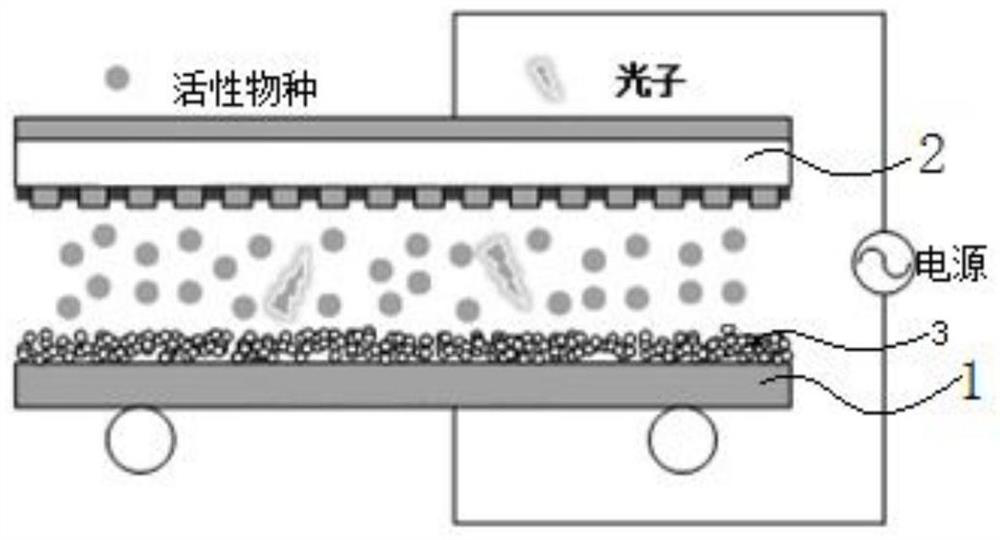

[0050] 3) At the processing temperature T, the controller sends a control signal to the power supply, so that the power supply discharges to the plasma generator 2 located above the polyimide conveyor belt 1 .

[0051]The power supply transmits alternating current to the plasma generator 2 .

[0052] 4) After the plasma generator...

Embodiment 2

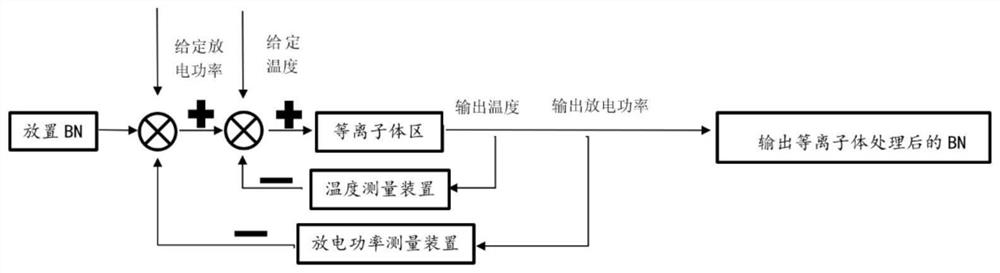

[0060] See Example 1 for the high-throughput hydroxylation method of inorganic fillers based on low-temperature plasma. The device used in this method includes a polyimide conveyor belt 1, a roll-to-roll device, a power supply, a plasma generator 2, a controller, and a temperature measurement device and discharge power measuring device.

[0061] The conveyor belt 1 is used for containing and conveying boron nitride.

[0062] The boron nitride of the counter-roller device drives the conveyor belt 1 to move, so that the boron nitride moves to the plasma region.

[0063] The power supply supplies power to the plasma generator 2 .

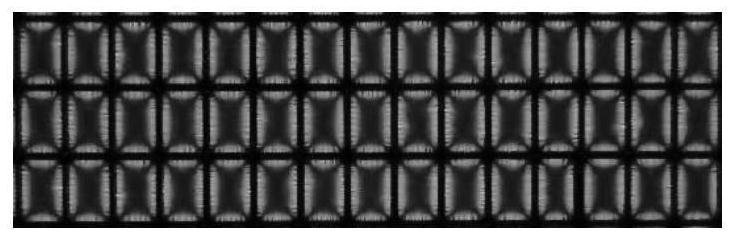

[0064] The plasma generator 2 generates atmospheric-pressure low-temperature plasma in the plasma generation area. The atmospheric-pressure low-temperature plasma treats the boron nitride powder 3 located in the plasma region to obtain boron nitride grafted with -OH groups (hydroxyl groups).

[0065] The temperature measuring device monitors the tem...

Embodiment 3

[0070] see Figure 1 to Figure 3 , a low-temperature plasma-based high-throughput hydroxylation method for inorganic fillers, comprising the following steps:

[0071] 1) Spread the aluminum nitride powder 3 to be processed on the conveyor belt 1 . The material of the conveyor belt 1 includes polyimide.

[0072] The average particle size of the aluminum nitride powder 3 is 1 μm˜5 μm.

[0073] 2) Using a roll-to-roll device to drive the conveyor belt 1 to move, so that the flat aluminum nitride powder 3 moves to the plasma area.

[0074] The roll-to-roll device includes several rollers for driving the polyimide conveyor belt 1 to move.

[0075] 3) At the processing temperature T, the controller sends a control signal to the power supply, so that the power supply discharges to the plasma generator 2 located above the polyimide conveyor belt 1 .

[0076] The power supply transmits alternating current to the plasma generator 2 .

[0077] 4) After the plasma generator 2 receive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com