Electroslag remelting method for nickel-based superalloy

A nickel-based superalloy and electroslag remelting technology, applied in the field of metallurgy, can solve the problems of uneven composition, unstable composition of electroslag metallurgy, poor high temperature strength and structural stability of domestic superalloys, etc. The effect of reducing the supercooling of components and improving the heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The electroslag remelting consumable electrode in this embodiment is a nickel-based superalloy with a specification of Φ120×1500mm, and its composition is: C 0.1%, Si 0.03%, Mn 0.04%, P 0.012%, S 0.005%, Cr 17%, Mo 3.3%, Ni 50%, Ti 1.15%, Al 0.2%, Nb 4.75%, the balance is iron and unavoidable impurities. The size of the crystallizer is Φ150×600mm, and a Co60 liquid level detection device and a stirring coil are built in at a distance of 200-400mm from the upper edge of the crystallizer. Carry out electroslag remelting according to the following steps:

[0035] (1) η=Al / Ti=0.2 / 1.15=0.174,

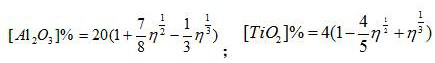

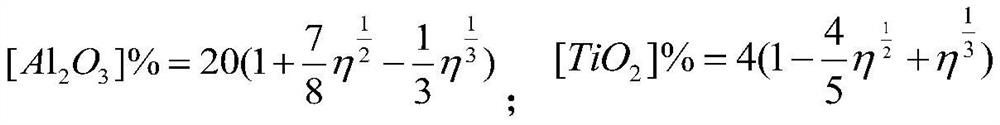

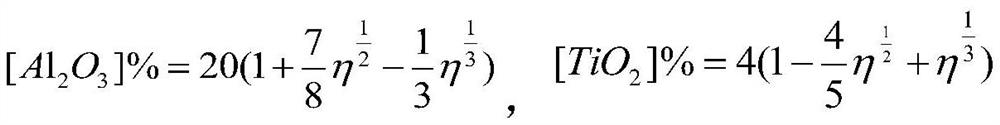

[0036]

[0037] Calculate the Al in the slag system according to the above formula 2 o 3 、TiO 2 The weight contents of the slag are 23.6% and 4.9%, respectively, and the weight contents of other components of the slag system are respectively CaF 2 : 55%, CaO: 16.5%;

[0038] Mixed CaF 2-CaO-Al 2 o 3 -TiO 2 5kg of slag is energized and melted. After melting, the temperatur...

Embodiment 2

[0051] The electroslag remelting self-consumable electrode in this embodiment is a nickel-based superalloy with a specification of Φ210×1800 mm, and its composition is: C0.08%, Si 0.025%, Mn 0.035%, P 0.015%, S 0.005%, Cr 19%, Mo 3% , Ni 52%, Ti0.65%, Al 1.25%, Nb 5.05%, and the balance is iron and unavoidable impurities. The size of the crystallizer is Φ300×700mm, and a Co60 liquid level detection device and a stirring coil are built in at a distance of 200-400mm from the upper edge of the crystallizer. Carry out electroslag remelting according to the following steps:

[0052] (1) η=Al / Ti=1.25 / 0.65=1.92,

[0053]

[0054] Calculate the Al in the slag system according to the above formula 2 o 3 、TiO 2 The weight content of the slag is 36%, 4.5%, respectively, and the weight content of other components of the slag system is CaF 2 : 44.5%, CaO: 15%;

[0055] Mixed CaF 2 -CaO-Al 2 o 3 -TiO 2 30kg of slag is energized and melted. After melting, the temperature is rais...

Embodiment 3

[0068] The electroslag remelting self-consumable electrode in this embodiment is a nickel-based superalloy with a specification of Φ300×2000 mm, and its composition is: C0.06%, Si 0.035%, Mn 0.035%, P 0.005%, S 0.008, Cr 21%, Mo 2.8%, Ni 55%, Ti 1.05%, Al 1.95%, Nb 5.55%, and the balance is iron and unavoidable impurities. The size of the crystallizer is Φ400×850mm, and a Co60 liquid level detection device and a stirring coil are built in at a distance of 200-400mm from the upper edge of the crystallizer. Carry out electroslag remelting according to the following steps:

[0069] (1) η=Al / Ti=1.95 / 1.05=1.86,

[0070]

[0071] Calculate the Al in the slag system according to the above formula 2 o 3 、TiO 2 The weight contents of the slag are 35.6% and 4.55%, respectively, and the weight contents of other components of the slag system are respectively CaF 2 : 30%, CaO: 30%;

[0072] Mixed CaF 2 -CaO-Al 2 o 3 -TiO 2 50kg of slag is energized and melted. After melting, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com