Interpenetrating mullite/boron carbide foamed ceramic high-temperature-resistant neutron shielding material and preparation method thereof

A technology of foam ceramics and shielding materials, which is applied in the field of interpenetrating mullite/boron carbide foam ceramic high-temperature-resistant neutron shielding materials and its preparation, can solve the problems of large grain boundary movement resistance, difficult preparation, and high process cost. It achieves the effects of excellent corrosion resistance and radiation resistance, good radiation resistance and ductility, and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

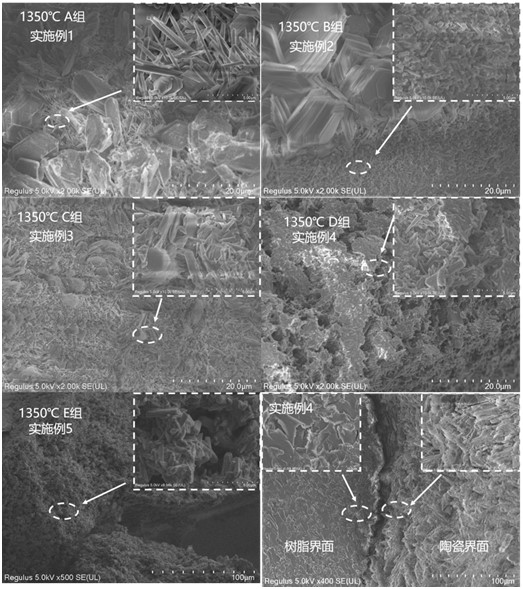

Embodiment 1

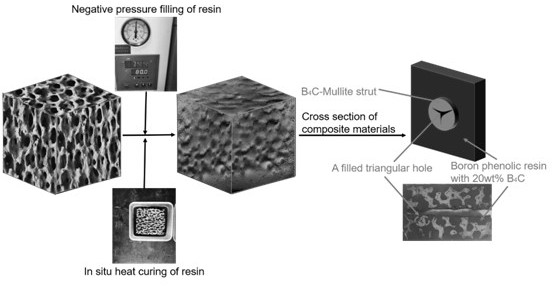

[0035] An interpenetrating mullite / boron carbide foam ceramic high temperature resistant neutron shielding material, the production steps are as follows:

[0036] Step 1. Ingredients: (set as powder ratio A) mix 30 parts by mass of boron carbide micropowder, 55 parts by mass of alumina micropowder, 10 parts by mass of superfine kaolin, and 5 parts by mass of titanium dioxide micropowder as a sintering aid, Obtain 100 parts of quality mixed powder I; then add 0.5 parts of quality polycarboxylate, 0.7 parts of quality of sodium carboxymethyl cellulose, 0.7 parts of quality of polyvinyl alcohol and 1.0 parts of quality to 61.3 parts of quality of deionized water of absolute ethanol to obtain mixed solution II;

[0037] Step 2. Mixing and impregnating: Weigh the grinding balls in a certain proportion by weight, the ball-to-material ratio = 1:1; add the mixed powder Ⅰ, mixed solution Ⅱ and grinding balls into the ball milling tank one by one, and mechanically mill for 3 hours to prep...

Embodiment 2

[0042] An interpenetrating mullite / boron carbide foam ceramic high-temperature-resistant neutron shielding material, the production steps described in this example are the same as in Example 1, the difference is that the composition ratio of the micropowder is changed to 25 parts by mass of carbonized Boron micropowder, 55 parts by mass of alumina micropowder, 15 parts by mass of superfine kaolin, and 5 parts by mass of titanium dioxide micropowder as a sintering aid——set as powder ratio B.

[0043] The remaining steps and parameters are consistent with those in Embodiment 1, and will not be described again.

[0044] The novel neutron shielding material prepared in Example 2 has been tested: the volume density of the boron carbide ceramic skeleton is 0.67g / cm 3 , the bulk density of the new neutron shielding material is 1.30g / cm 3 ; The normal temperature compressive strength of the boron carbide ceramic skeleton is 1.31 MPa, and the normal temperature compressive strength of...

Embodiment 3

[0046] An interpenetrating mullite / boron carbide foam ceramic high-temperature-resistant neutron shielding material, the production steps described in this example are the same as in Example 1, the difference is that the composition ratio of the micropowder is changed to 20 parts by mass of carbonized Boron micropowder, 55 parts by mass of alumina micropowder, 20 parts by mass of superfine kaolin, and 5 parts by mass of titanium dioxide micropowder as a sintering aid——set as powder ratio C.

[0047] The remaining steps and parameters are consistent with those in Embodiment 1, and will not be described again.

[0048] The novel neutron shielding material prepared in Example 3 has been tested: the volume density of the boron carbide ceramic skeleton is 0.66g / cm 3 , the bulk density of the new neutron shielding material is 1.18g / cm 3 ; The room temperature compressive strength of the boron carbide ceramic skeleton is 1.04 MPa, and the room temperature compressive strength of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com