Compound liquorice tablet capable of being prepared by dry powder direct compression process and preparation method of compound liquorice tablet

A technology for direct pressing of compound licorice tablets and dry powder, which is applied in the directions of non-active ingredients medical preparations, medical preparations containing active ingredients, and pharmaceutical formulas, etc. It can reduce the loss of volatile oil, ensure the content uniformity, and improve the compressibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

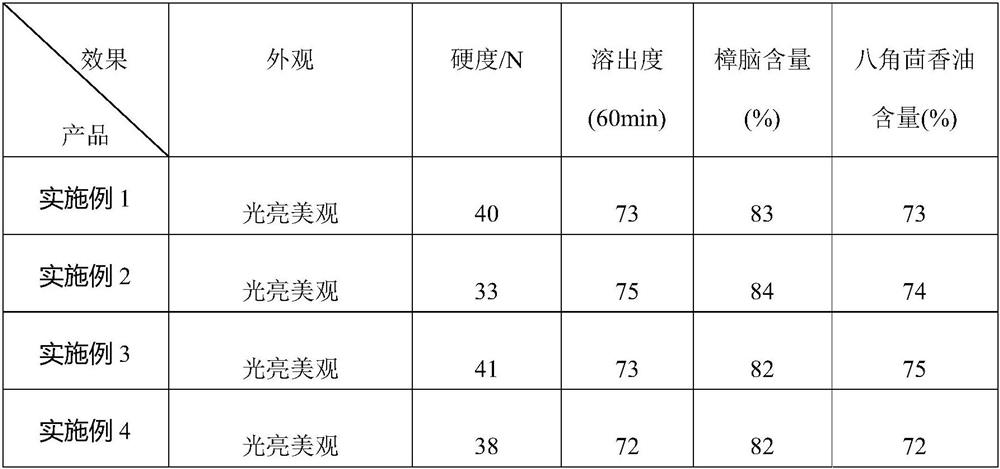

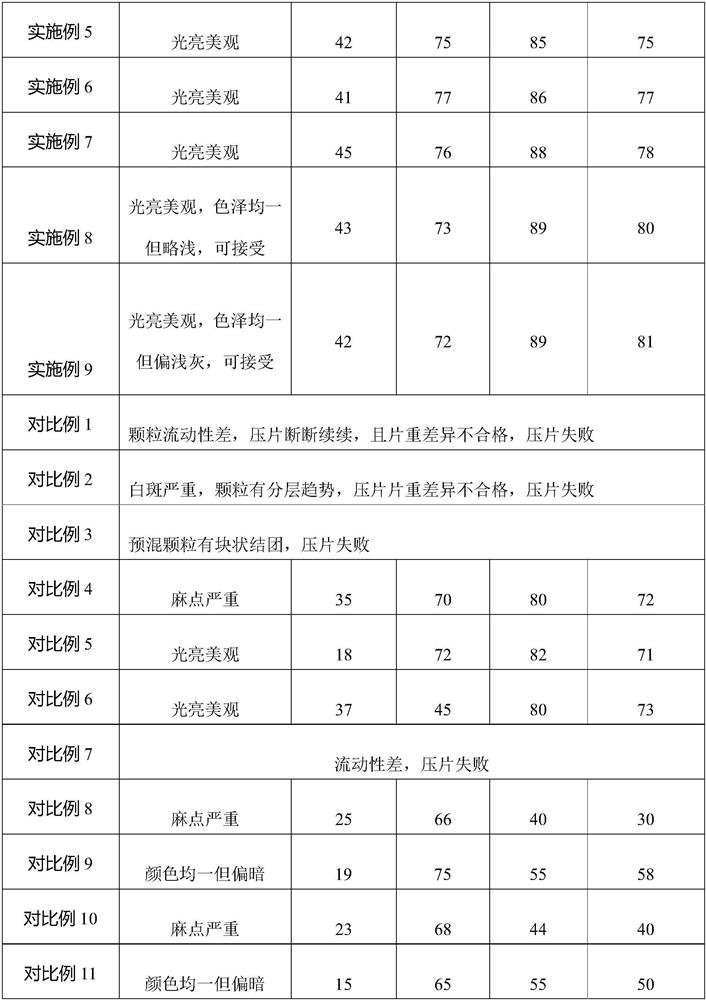

Examples

Embodiment 1

[0051] A kind of preparation method of the compound licorice tablet that can use dry powder direct compression process, comprises the steps:

[0052] (1) Weighing: Weigh according to 10000 tablets, and take raw and auxiliary materials, namely licorice extract 1125.0g, poppy fruit extract powder 40g, sodium benzoate 20g, camphor 20g, star anise oil 20g, silicon dioxide 40g, micro Crystalline cellulose 50g, lactose 50g, polyvinylpyrrolidone (VA64) 20g, talcum powder 50g, magnesium stearate 30g, spare;

[0053] (2) Initial mixing: the licorice extract, poppy fruit extract powder and sodium benzoate described in step (1) are placed in the same plastic bag, recorded as the initial mixture, and the initial mixture is mixed evenly and passed through a universal pulverizer 100 Mesh, so that the average particle size is about 70 μm, to obtain material a;

[0054] (3) Sieving: Pass the microcrystalline cellulose, lactose and polyvinylpyrrolidone (VA64) described in step (1) through a 6...

Embodiment 2

[0061] This example is basically the same as Example 1, the only difference being that the microcrystalline cellulose 50g and the lactose 50g in the step (1) in Example 1 are replaced by the microcrystalline cellulose 0g and the Lactose 0g.

Embodiment 3

[0063] This example is basically the same as Example 1, the only difference being that the microcrystalline cellulose 50g and the lactose 50g in step (1) in Example 1 are replaced by the microcrystalline cellulose 100g and the Lactose 0g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com