Method for preparing functional grape seed nanosphere particles by using grape seeds and product thereof

A grape seed and nanosphere technology, applied in the field of nanosphere particles, can solve the problems of difficulty in preparing spherical lignin nanoparticles, many types of lignin nanoparticle solvents, unsuitable for promotion and utilization, etc. The effect of high UV absorption capacity and strong UV absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

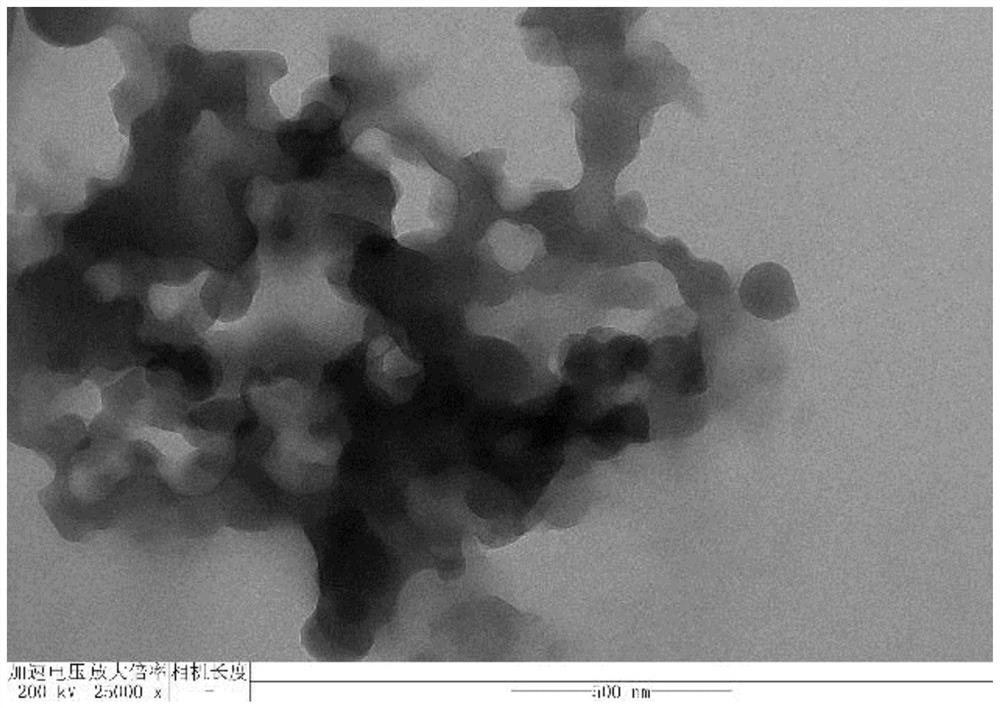

[0052] Embodiment 1: utilize grape seed to prepare the method for grape seed nanosphere particle

[0053] (1) drying the grape seed residue comprising grape seeds, grape skins and grape stems in an oven at 40° C. after brewing; sieving the grape seeds in the residue after drying;

[0054] (2) pulverize the dried and sieved grape seeds, and pass through a 20-mesh sieve to collect grape seed powder;

[0055] (3) Mix grape seed powder and petroleum ether at a solid-to-liquid ratio of 1:10 (1Kg / 10L) for petroleum ether-ultrasound-assisted extraction of grape seed oil, during which leaching lasts for 200 minutes and ultrasonic treatment for 20 minutes;

[0056] (4) Conventional centrifugation, separating the petroleum ether extract from the grape seed powder, collecting the grape seed powder, washing with water, and drying at 40°C;

[0057] (5) further ball milling the dried grape seed powder for 40-48h under the condition of 250-300rpm;

[0058] (6) Mix the ball-milled grape see...

Embodiment 2

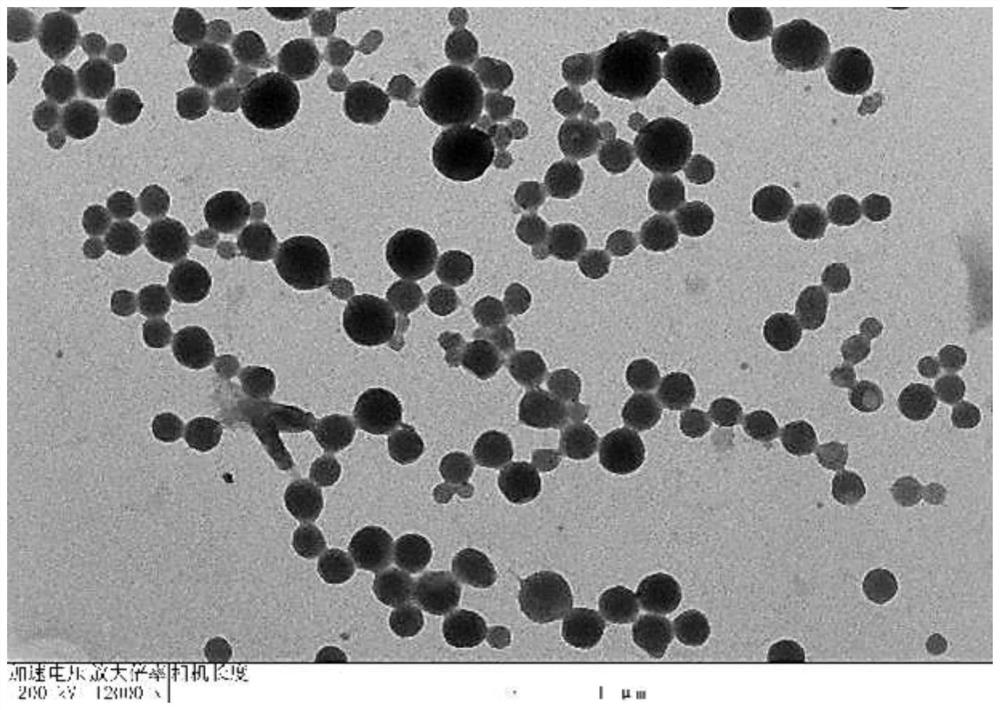

[0064] Embodiment 2: utilize grape seed to prepare the method for grape seed nanosphere particle

[0065] (1) drying the grape seed residue comprising grape seeds, grape skins and grape stems in an oven at 40° C. after brewing; sieving the grape seeds in the residue after drying;

[0066] (2) pulverize the dried and sieved grape seeds, and pass through a 20-mesh sieve to collect grape seed powder;

[0067] (3) Mix grape seed powder and petroleum ether at a solid-to-liquid ratio of 1:10 (1Kg / 10L) for petroleum ether-ultrasound-assisted extraction of grape seed oil, during which leaching lasts for 200 minutes and ultrasonic treatment for 20 minutes;

[0068] (4) Conventional centrifugation, separating the petroleum ether extract from the grape seed powder, collecting the grape seed powder, washing with water, and drying at 40°C;

[0069] (5) further ball milling the dried grape seed powder for 40-48h under the condition of 250-300rpm;

[0070] (6) Mix the ball-milled grape see...

Embodiment 3

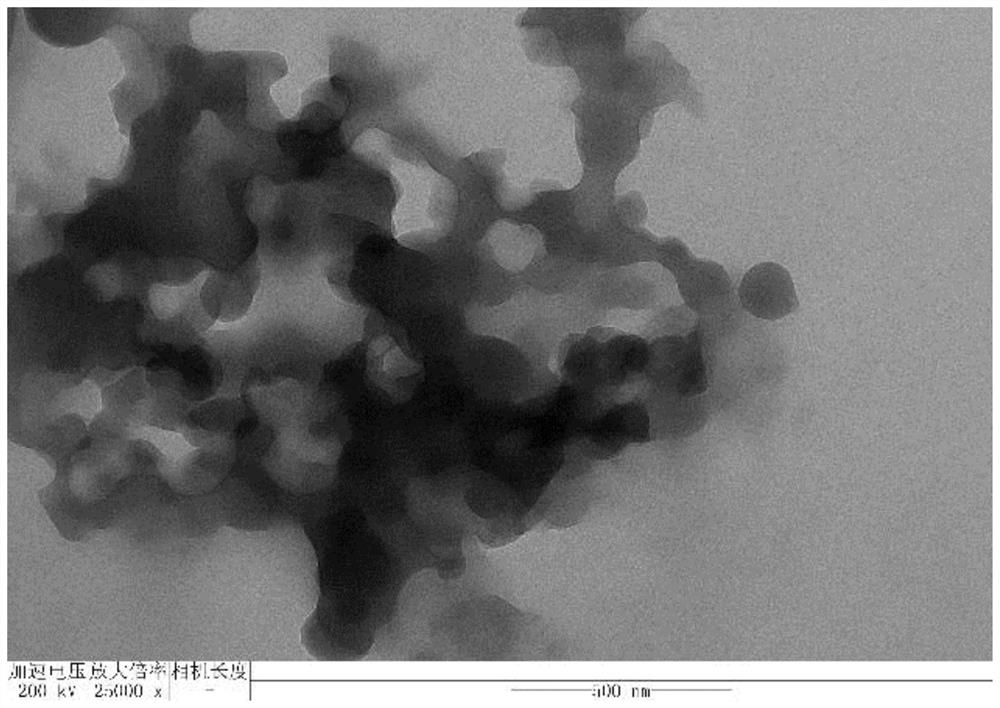

[0076] Embodiment 3: utilize grape seed to prepare the method for grape seed nanosphere particle

[0077] (1) drying the grape seed residue comprising grape seeds, grape skins and grape stems in an oven at 40° C. after brewing; sieving the grape seeds in the residue after drying;

[0078] (2) pulverize the dried and sieved grape seeds, and pass through a 20-mesh sieve to collect grape seed powder;

[0079] (3) Mix grape seed powder and petroleum ether at a solid-to-liquid ratio of 1:10 (1Kg / 10L) for petroleum ether-ultrasound-assisted extraction of grape seed oil, during which leaching lasts for 200 minutes and ultrasonic treatment for 20 minutes;

[0080] (4) Conventional centrifugation, separating the petroleum ether extract from the grape seed powder, collecting the grape seed powder, washing with water, and drying at 40°C;

[0081] (5) further ball milling the dried grape seed powder for 40-48h under the condition of 250-300rpm;

[0082] (6) Mix the ball-milled grape see...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com