Inorganic formaldehyde-removing fireproof water-based paint

A water-based paint, inorganic technology, applied in fire-resistant paint, anti-corrosion paint, coating and other directions, can solve the problem of easy release of toxic and harmful substances of formaldehyde, and achieve good formaldehyde purification, strong flame retardancy, and good flame retardant effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

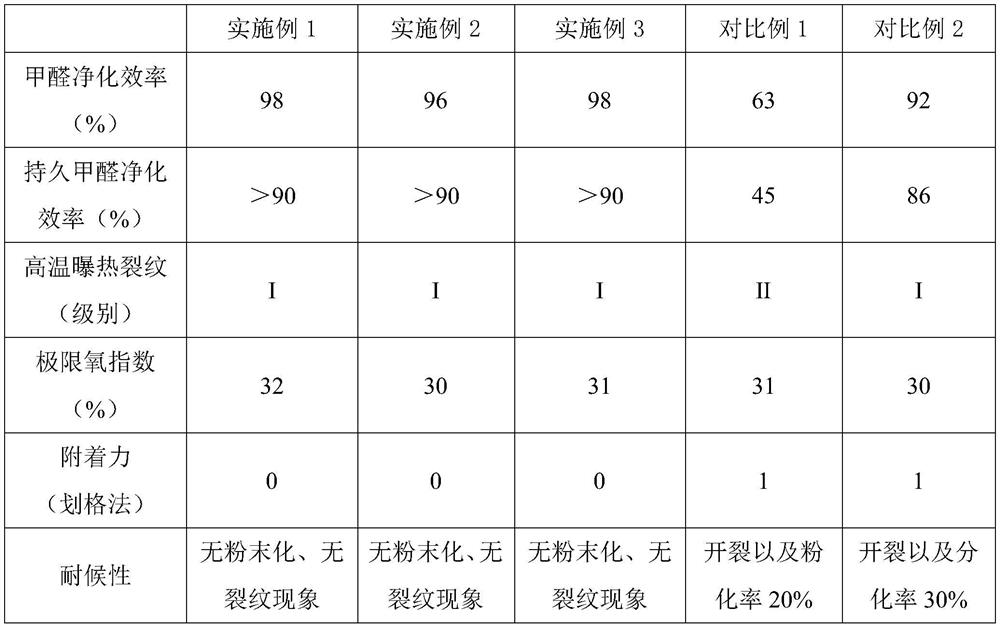

Examples

Embodiment 1

[0038] An inorganic aldehyde-removing fire-resistant water-based paint, calculated in parts by weight, includes the following components:

[0039] 68 parts of water-based epoxy modified acrylic resin, 11 parts of inorganic aldehyde-removing modifier, 8 parts of flame retardant, 0.3 part of HY-1608A wetting and dispersing agent, 0.2 part of dodecyl alcohol ester, polydimethylsiloxane 0.1 parts and 21 parts of deionized water.

[0040] The flame retardant is obtained by mixing melamine phosphate, zinc borate and magnesium hydroxide in a mass ratio of 0.3:1:0.3.

[0041] The preparation method of waterborne epoxy modified acrylic resin is:

[0042] Weigh the epoxy resin and mix it into diethylene glycol butyl ether, heat up to 110°C, stir and disperse evenly, then add methyl methacrylate, acrylic acid and styrene in sequence, after mixing evenly, add ammonium persulfate, and stir to react After 3 hours, the temperature was lowered to 75°C, and the reaction was continued for 1.5...

Embodiment 2

[0050] An inorganic aldehyde-removing fire-resistant water-based paint, calculated in parts by weight, includes the following components:

[0051] 62 parts of water-based epoxy modified acrylic resin, 6 parts of inorganic aldehyde-removing modifier, 5 parts of flame retardant, 0.1 part of HY-352 wetting and dispersing agent, 0.1 part of propylene glycol ether, 0.05 part of polyether-siloxane copolymer and 15 parts of deionized water.

[0052] The preparation method of waterborne epoxy modified acrylic resin is:

[0053] Weigh the epoxy resin and mix it into diethylene glycol butyl ether, heat up to 100°C, stir and disperse evenly, then add methyl methacrylate, acrylic acid and styrene in sequence, after mixing evenly, add benzoyl peroxide, After stirring and reacting for 2h, cool down to 65°C and continue to react for 1h to obtain water-based epoxy-modified acrylic resin; the mass ratio of epoxy resin, methyl methacrylate, acrylic acid, styrene and diethylene glycol butyl eth...

Embodiment 3

[0062] An inorganic aldehyde-removing fire-resistant water-based paint, calculated in parts by weight, includes the following components:

[0063] 75 parts of water-based epoxy modified acrylic resin, 18 parts of inorganic aldehyde-removing modifier, 10 parts of flame retardant, 0.5 part of HY-6170 wetting and dispersing agent, 0.3 part of ethylene glycol butyl ether acetate, GPE type polyoxyethylene 0.2 parts of ether and 30 parts of deionized water.

[0064] The preparation method of waterborne epoxy modified acrylic resin is:

[0065] Weigh epoxy resin and mix it into diethylene glycol butyl ether, raise the temperature to 120°C, stir and disperse evenly, then add methyl methacrylate, acrylic acid and styrene in turn, after mixing evenly, add methyl ethyl ketone peroxide, and stir to react After 2 to 5 hours, cool down to 85°C and continue the reaction for 2 hours to obtain a water-based epoxy-modified acrylic resin; the mass ratio of epoxy resin, methyl methacrylate, acry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com