Polyurethane acrylate dispersoid and preparation method thereof, and high-performance water-based wood coating and preparation method thereof

A polyurethane acrylate and acrylate technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as high reaction temperature, difficult control, complex process, etc., and achieve good flexibility, good anti-blocking, and high transparency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

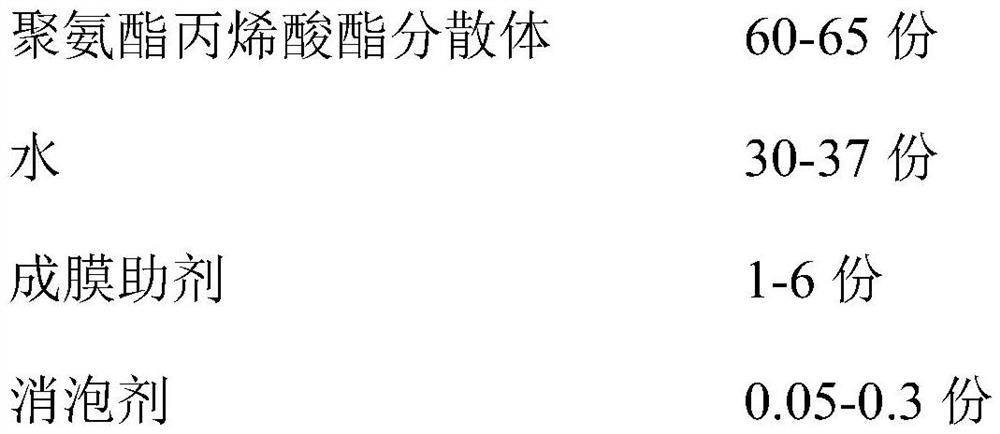

Method used

Image

Examples

Embodiment 1

[0048] A polyurethane acrylate dispersion 1, which is prepared by the following steps:

[0049] S1. In parts by mass, mix 11.7 parts of acrylic acid, 23 parts of methyl methacrylate, 20 parts of styrene, 8.7 parts of butyl acrylate, 5 parts of isobornyl acrylate and 1.5 parts of di-tert-amyl peroxide Form mixed solution A1 for later use;

[0050] S2. In parts by mass, 2.1 parts of ethylenediamine and 17.9 parts of deionized water are uniformly mixed to form a mixed solution B1 for later use;

[0051] S3. Add 10 parts of polyether diols and 30 parts of glycidyl tertiary carbonate monomers into a four-necked flask equipped with a thermometer, condenser, stirring paddle and constant pressure dropping funnel, mix and heat, when the temperature reaches 145 After ℃, start to add the mixed solution A1 dropwise, and finish dropping in 4 hours. After dropping, stir and keep warm for 30 minutes, cool down to 80°C, add 23.6 parts of isophorone diisocyanate, NCO / OH is 1.5, stir for 5 min...

Embodiment 2

[0060] A polyurethane acrylate dispersion 2, which is prepared by the following steps:

[0061] S1. In parts by mass, 13.5 parts of methacrylic acid, 18 parts of methyl methacrylate, 17 parts of styrene, 12 parts of butyl acrylate, 8 parts of isobornyl methacrylate and 2 parts of di-tert-amyl peroxide The oxides are mixed evenly to form a mixed solution A2, which is set aside;

[0062] S2. In terms of parts by mass, 7.1 parts of isophoronediamine and 22.9 parts of deionized water are mixed evenly to form a mixed solution B2, which is set aside;

[0063] S3. add 12 parts of polybutylene adipate glycols and 25 parts of 4-t-butyl glycidyl benzoate in the four-necked flask equipped with thermometer, condenser, stirring paddle and constant pressure dropping funnel, Mix and stir and heat. When the temperature reaches 140°C, start to add the mixed solution A2 dropwise. After 4.5 hours, stir and keep warm for 30 minutes. Cool down to 80°C, add 17.6 parts of toluene diisocyanate, NCO / ...

Embodiment 3

[0073] A polyurethane acrylate dispersion 3, which is prepared by the following steps:

[0074] S1. In terms of parts by mass, mix 11 parts of acrylic acid, 25 parts of methyl methacrylate, 14.5 parts of styrene, 7 parts of butyl acrylate, 10 parts of tertiary vinyl carbonate and 2.5 parts of di-tert-amyl peroxide Form the mixed solution A3 for later use;

[0075] S2. In terms of parts by mass, 3.8 parts of hexamethylenediamine and 16.2 parts of deionized water are uniformly mixed to form a mixed solution B3 for later use;

[0076]S3. Add 7 parts of polycarbonate diols and 35 parts of glycidyl stearate in a four-necked flask equipped with a thermometer, condenser, stirring paddle and constant pressure dropping funnel, mix and heat, when the temperature reaches 150 After ℃, start to add the mixed solution A3 dropwise, and finish dropping in 5 hours. After dropping, stir and keep warm for 20 minutes, cool down to 75°C, add 22 parts of diphenylmethane diisocyanate, NCO / OH is 1.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com