Method for manufacturing selective welding nozzle, selective welding nozzle and selective welding assembly

A manufacturing method and nozzle technology, which are applied to the manufacturing method of selective welding nozzles, selective welding nozzles and selective welding components, can solve the problems of easy corrosion and damage of nozzles, poor thermal conductivity of nozzles, and changes in surface morphology, and reduce electrochemical Corrosion rate, low carbon content, effect of slowing corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

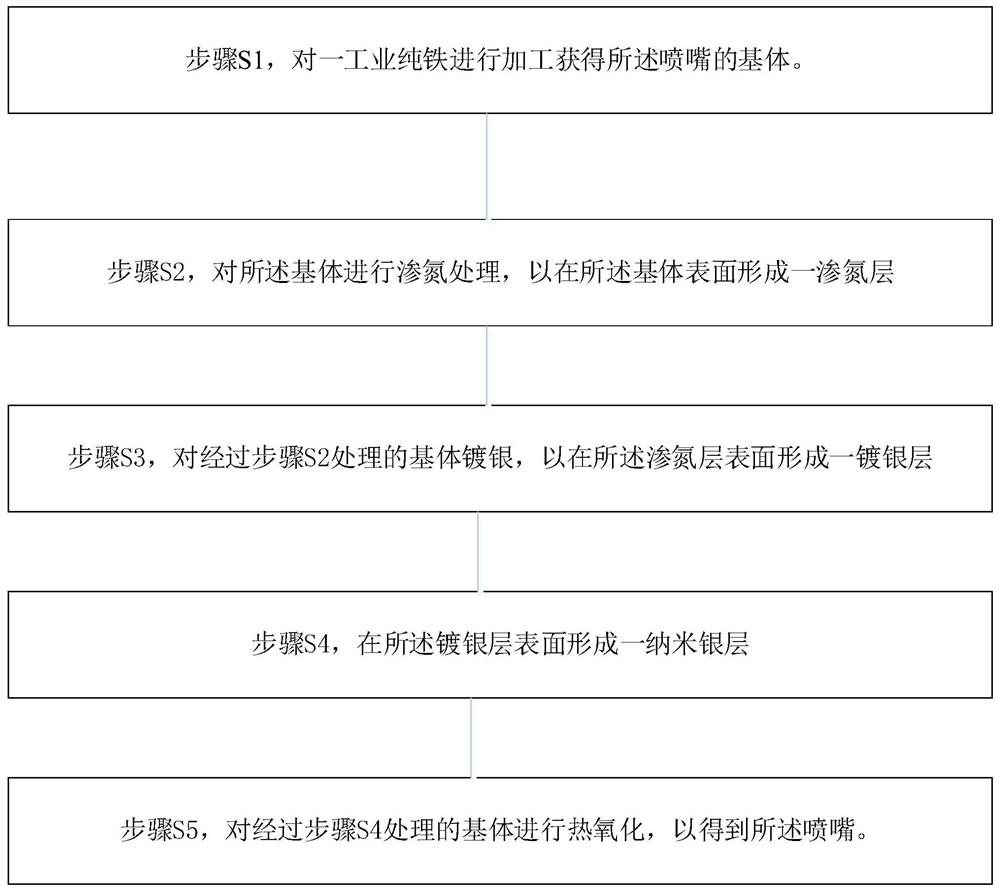

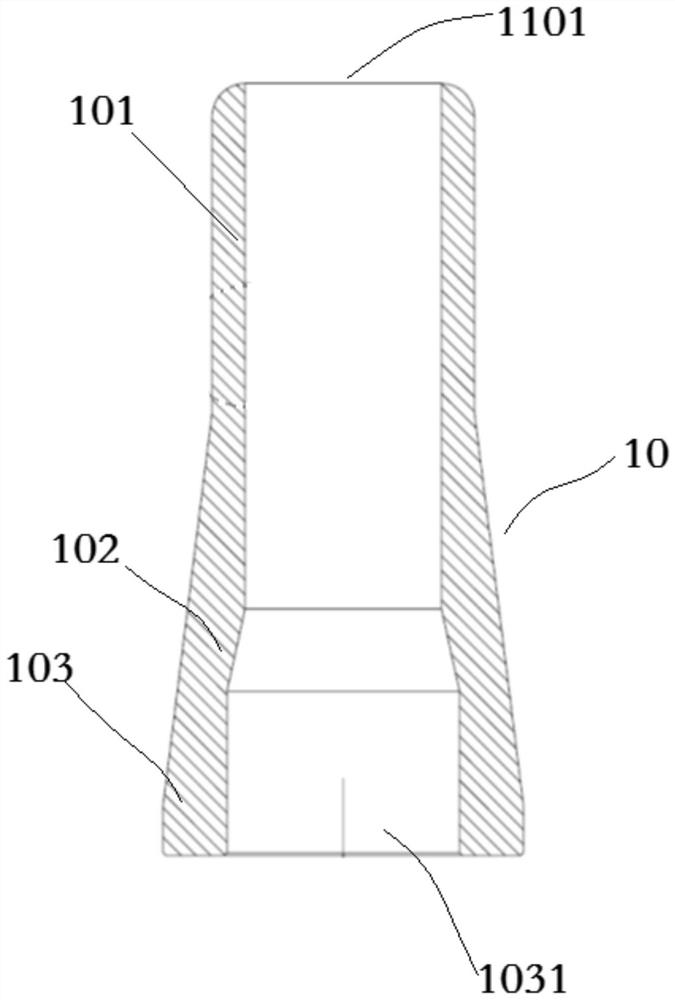

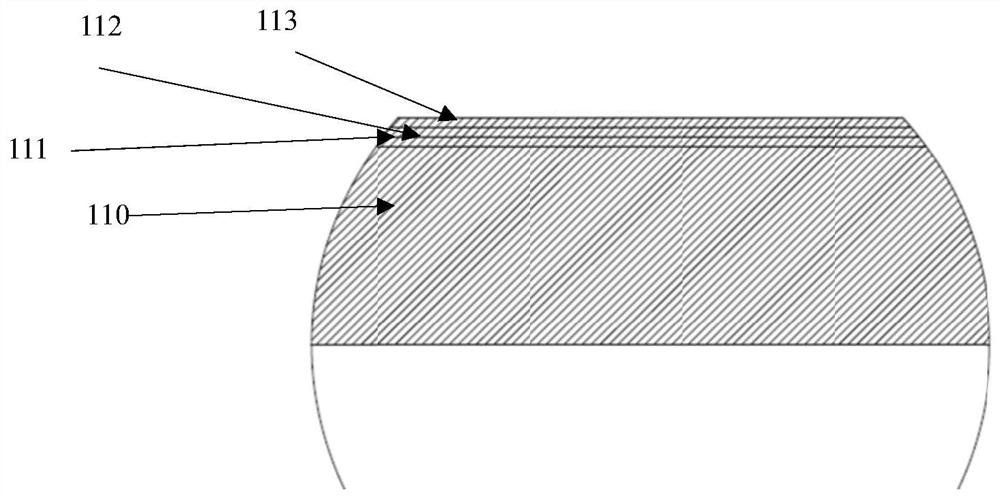

[0110] The selective welding nozzle in the first embodiment of the present invention has a composite structure, including a substrate 110 , a nitrided layer 111 , a silver-plated layer 112 and a nano-silver oxide surface structure 113 in sequence. The carbon content of the substrate 110 is 0.03%, the iron content is 99.9%, and the content of other elements is 0.07%. The nozzle substrate 110 is processed by turning and finely ground. Microns. The nozzle base 110 is subjected to pressurized gas nitriding treatment for 5 hours in a pressurized nitriding furnace to obtain a surface nitrided layer 111 with a thickness of 1000 microns, wherein the temperature of the pressurized nitriding furnace is 550°C and the pressure is 5atm . Adopt a hanger to hang-plate mist silver on the surface of the nozzle to form a silver-plated layer 112 on the surface of the nitrided layer 111. The thickness of the silver-plated layer 112 is 10 microns, and the surface roughness of the substrate 110 wi...

no. 2 example

[0114] The process steps of making the selective welding nozzle of the second embodiment of the present invention, the shape and specific size of the selective welding nozzle are basically the same as those of the first embodiment. The difference between the selective welding nozzle of this embodiment and the first embodiment is that The carbon content in the material components of the substrate 110 is 0.02%, the iron content is 99.9%, and the remaining elements are 0.08%. The inner and outer surface roughness of the nozzle substrate 110 is 0.05 microns, the thickness of the nitrided layer 111 is 800 microns, and the thickness of the silver-plated layer 112 is 30 microns, the average diameter of the silver oxide particles of the nano-silver oxide surface structure 113 ranges from 50 nanometers.

no. 3 example

[0116] The selective welding assembly of the third embodiment of the present invention, the selective welding assembly includes a nozzle 10, a magnetic ring 20, a connecting head 30, a fixing slot 40 and an inner spray pipe 50, and the above-mentioned first embodiment is adopted in this embodiment. Select a welding nozzle. The magnetic ring 20 is made of a samarium cobalt magnet resistant to a high temperature of 350° C., and has a chromium nitride coating on the surface. When the magnetic ring 20 and the connector 30 are installed, the connector 30 is cooled to a suitable temperature to reduce the outer diameter of the boss 302, and then the magnetic ring 20 is put on to realize the cold interference fit between the connector 30 and the magnetic ring 20 . After the magnetic ring 20 is installed, the bottom of the connector 30 communicates with the inner nozzle 50 through the fixed slot 40, and then the nozzle 10 is set on the magnetic ring 20, and the magnetic ring 20 attrac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com