Active material, adsorption electrode, capacitive deionization device, preparation method and application thereof

An active material, deionized water technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high cost, poor adsorption effect, non-renewable and other problems, achieve simple operation, better effect, general adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A capacitive deionization adsorption electrode,

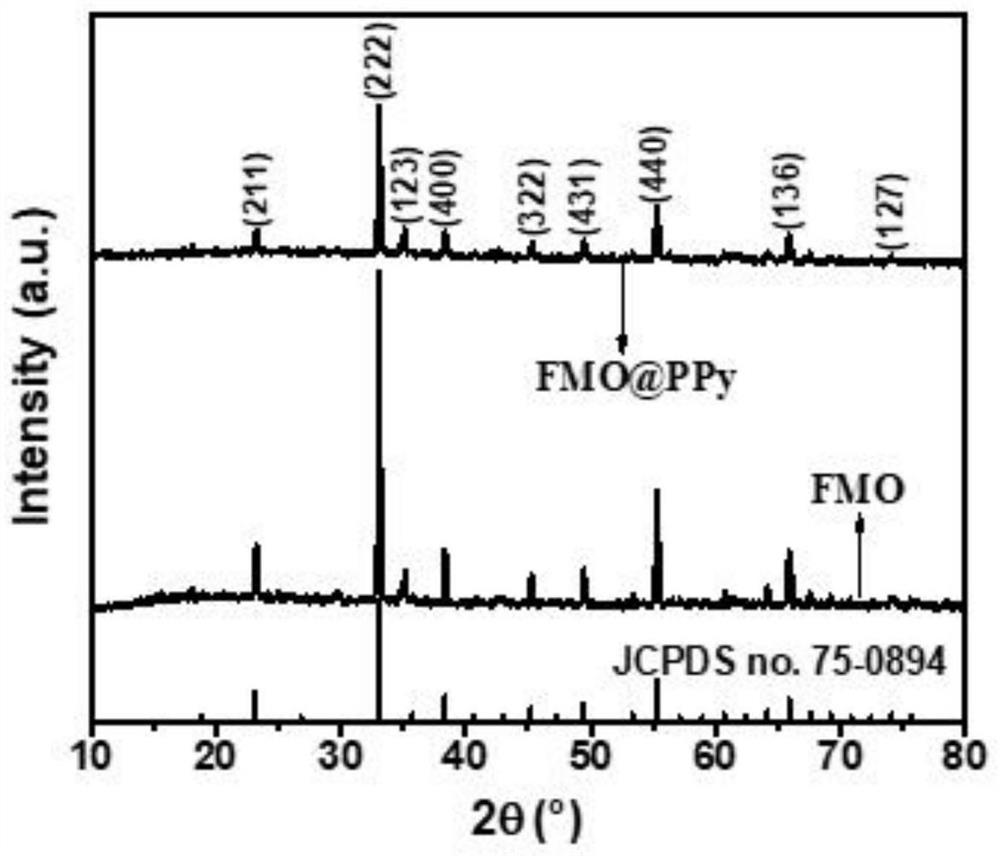

[0041] S1. Preparation of FMO: 5.2mmol of manganese acetate and 5.2mmol of ferric chloride were added to 50mL of deionized water as solution A, 15.67mmol of oxalic acid was dissolved in 50mL of deionized water as solution B, solution A and B were mixed and 27mL of 2M Sodium hydroxide, adjust the pH to about 9, then stand still for 2 hours, centrifuge, wash, dry, and grind to obtain FeMnO 3 precursor, and then calcined at 900 °C for 5 h to obtain FeMnO 3 powder;

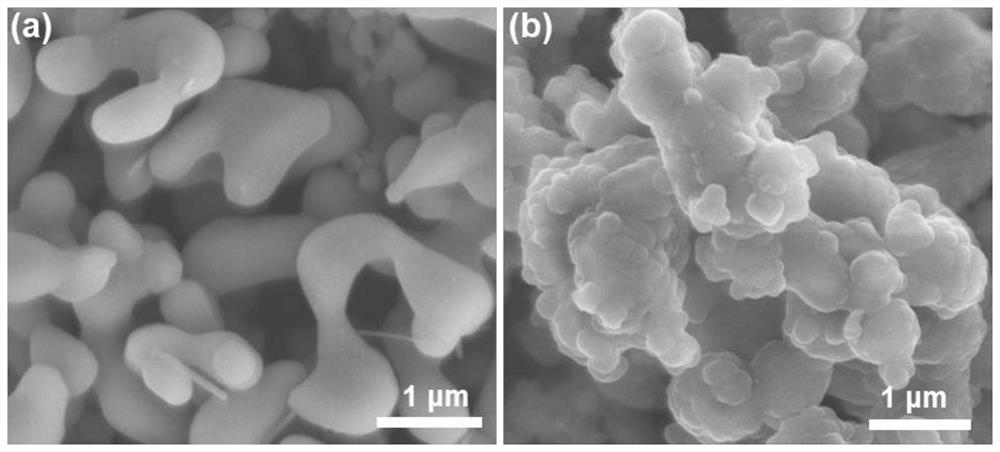

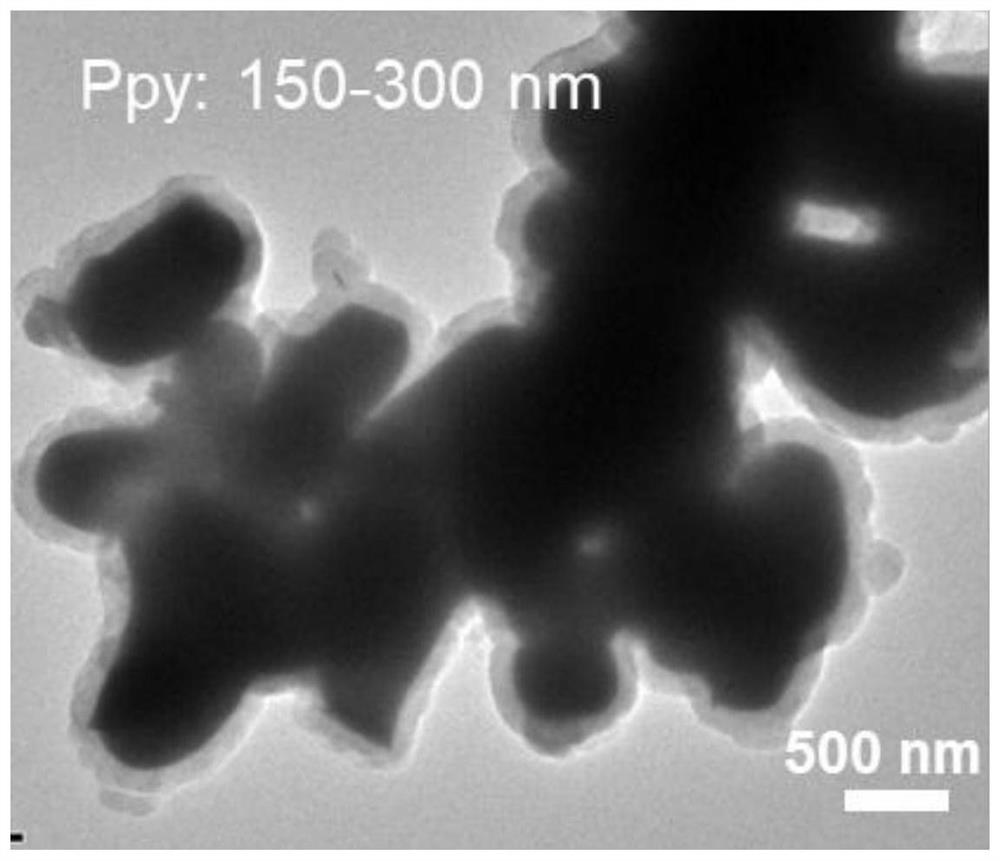

[0042] S2. Preparation of FMO@PPy: Take 200mg of FMO and disperse it in 100mL of deionized water. 10mg of sodium dodecylsulfonate has been added to the water. After stirring for one hour, add 53ul of liquid pyrrole, then stir for 1h, and finally add 10ml of 0.1M ammonium peroxate (228mg), continue to stir at room temperature for 3h, and finally centrifuge and dry to obtain FMO@PPy;

[0043] S3. Preparation of capacitive deionization adsorption electrode: Take...

Embodiment 2

[0053] Referring to Example 1, the difference is that the mass of FMO is changed to 400mg during the preparation of FMO@PPy.

[0054] The FMO@PPy prepared in Example 2 was measured, and the results are shown in the attached Figure 6 , the package thickness of PPy is 80-150nm.

Embodiment 3

[0056] Referring to Example 1, the difference is that in the preparation of FMO@PPy, the mass of FMO during ultrasonic dispersion is changed to 100 mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com