Anode/electrolyte half-cell, anode-supported solid oxide fuel cell and manufacturing method thereof

An anode support and electrolyte technology, applied in solid electrolyte fuel cells, fuel cell components, battery electrodes, etc., can solve the problems that hinder the rapid development of SOFC, the long-term stability is difficult to guarantee, and the battery manufacturing cost is high, so as to achieve excellent structural stability performance, improve electrochemical performance, and reduce the effect of polarization resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

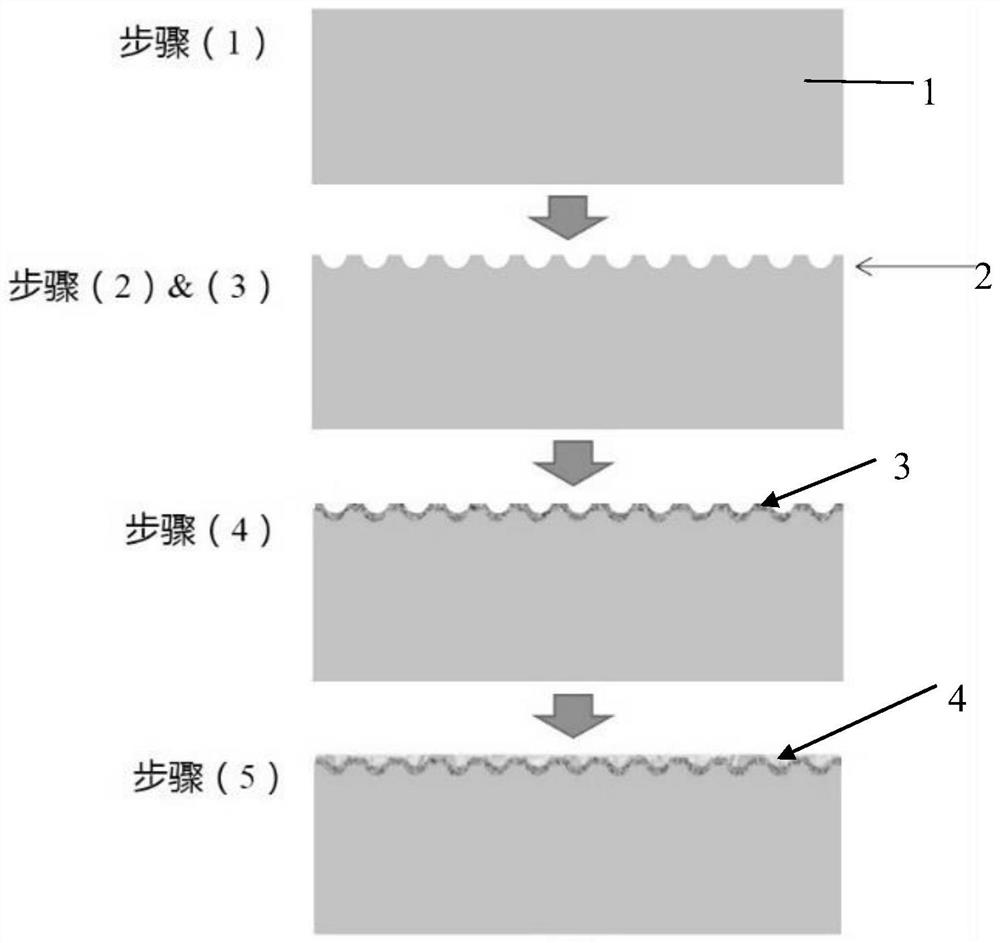

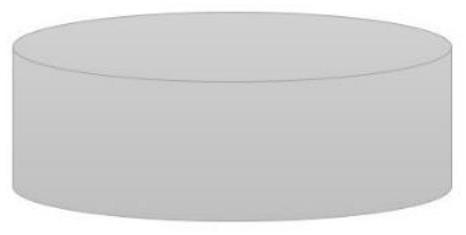

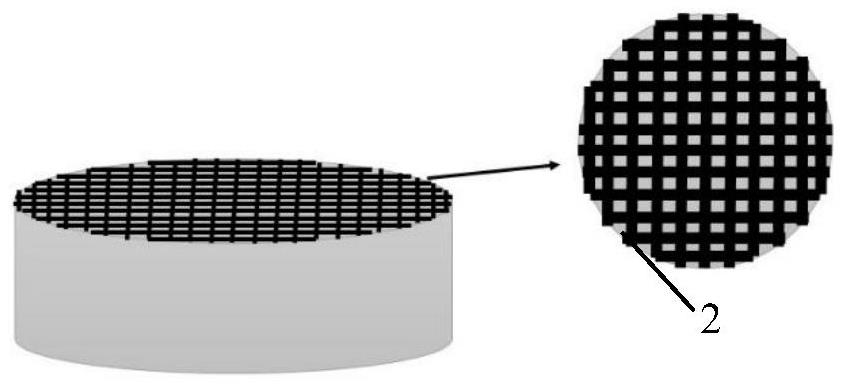

[0087] This embodiment provides an anode / electrolyte half-cell, and the schematic diagram of the product obtained in each step in the manufacturing method is as follows figure 1 shown, from figure 1 It can be seen that the preparation method includes the following specific steps:

[0088] Step (1): Prepare NiO-YSZ anode support casting sheet by casting method:

[0089] Weigh 6g of NiO, 4g of YSZ powder, 0.6g of PMMA and 0.05g of triethanolamine and dissolve them in a mixed solvent of 100g of ethanol and xylene, and mill the resulting mixture on a high-energy ball mill for 24 hours. After mixing evenly, add 0.2 g of polyvinyl butyral, 0.2 g of polymethyl acrylate and 0.5 g of ethyl cellulose to the resulting slurry, and continue ball milling for 12 hours. Subsequently, the mixed slurry is placed in a vacuum chamber for vacuum treatment to remove air bubbles in the slurry. Finally, the slurry is cast onto a polyester film, and after drying at room temperature, a NiO-YSZ anode...

Embodiment 2

[0100] This embodiment provides an anode / electrolyte half-cell, and its manufacturing method includes the following specific steps:

[0101] Step (1): Prepare NiO-YSZ anode support casting sheet by casting method:

[0102] Weigh 6g of NiO, 4g of YSZ powder, 0.6g of PMMA and 0.05g of triethanolamine and dissolve them in a mixed solvent of 100g of ethanol and xylene, and mill the resulting mixture on a high-energy ball mill for 24 hours. After mixing evenly, add 0.2 g of polyvinyl butyral, 0.2 g of polymethyl acrylate and 0.5 g of ethyl cellulose to the resulting slurry, and continue ball milling for 12 hours. Subsequently, the mixed slurry is placed in a vacuum chamber for vacuum treatment to remove air bubbles in the slurry. Finally, the slurry is cast onto a polyester film, and after drying at room temperature, a NiO-YSZ anode support casting sheet is obtained, and the thickness of the NiO-YSZ anode support casting sheet is 5 mm;

[0103] Step (2): Perform micro-processing ...

Embodiment 3

[0113] This embodiment provides an anode / electrolyte half-cell, and its manufacturing method includes the following specific steps:

[0114] Step (1): Prepare NiO-YSZ anode support casting sheet by casting method:

[0115] Weigh 6g of NiO, 4g of YSZ powder, 0.6g of PMMA and 0.05g of triethanolamine and dissolve them in a mixed solvent of 100g of ethanol and xylene, and mill the resulting mixture on a high-energy ball mill for 24 hours. After mixing evenly, add 0.2g polyvinyl butyral, 0.2g polymethyl acrylate and 0.5g ethyl cellulose to the slurry, and continue ball milling for 12 hours. Subsequently, the mixed slurry is placed in a vacuum chamber for vacuum treatment to remove air bubbles in the slurry. Finally, the slurry was cast onto a polyester film, and dried at room temperature to obtain a NiO-YSZ anode support casting sheet, and the thickness of the NiO-YSZ anode support casting sheet was 5mm;

[0116] Step (2): Perform micro-processing on one side of the NiO-YSZ anod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com