Modified perfluoroether fluororubber as well as preparation method and application thereof

A technology of perfluoroether and fluororubber, which is applied in the field of high temperature resistant modified perfluoroether fluororubber and its preparation. Good performance and processability, low hardness and low pressure change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

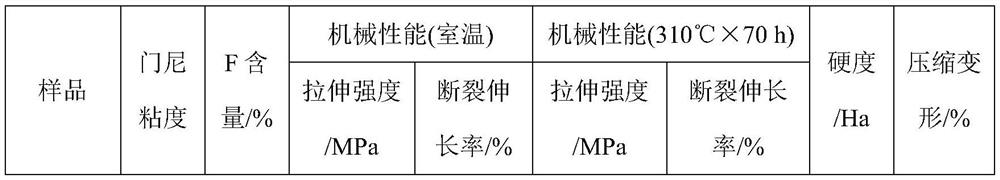

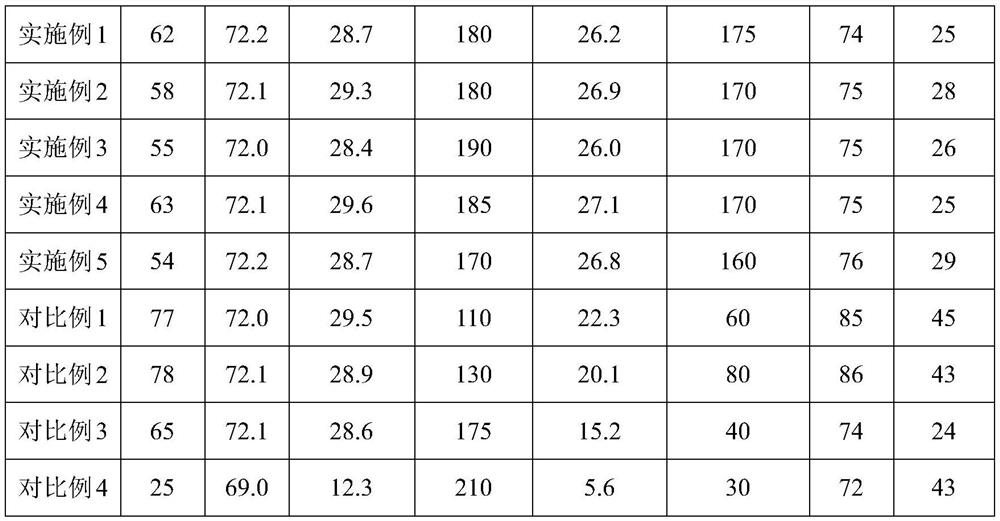

Image

Examples

preparation example 1

[0038] A kind of perfluoroether fluorine rubber emulsion, the preparation method is as follows:

[0039] (1) 30L of deionized water was added to a 50L reactor, the reactor was evacuated, and when its oxygen content was less than or equal to 30ppm, 35g of perfluorooctanoic acid ammonia was added and heated to 85°C.

[0040] (2) feed intake according to the mol ratio of tetrafluoroethylene and perfluoromethyl vinyl ether at 75:25, the reactor pressure is raised to 3.0MPa, and 15g potassium persulfate, 25g 1,2-diiodoperfluoroethyl ether are added. Alkane and 60g I(CF 2 ) 2 OCF=CF 2 , carry out the polymerization reaction, when the amount of the reacted monomers is 10kg, the reaction is terminated, the unreacted monomers are recovered, and the perfluoroether fluororubber emulsion is obtained.

preparation example 2

[0042] A kind of perfluoroether fluorine rubber emulsion, the preparation method is as follows:

[0043] (1) 30L of deionized water was added to a 50L reactor, the reactor was evacuated, and when its oxygen content was less than or equal to 30ppm, 50g of perfluorooctanoic acid ammonia was added and heated to 65°C.

[0044] (2) be 55:35 feed intake according to the mol ratio of tetrafluoroethylene and perfluoromethyl vinyl ether, the reactor pressure is raised to 3.5MPa, add 30g potassium persulfate, 50g 1,2-diiodoperfluoroethyl Alkane and 60g I(CF 2 ) 2 OCF=CF 2 , carry out the polymerization reaction, when the amount of the reacted monomers is 10kg, the reaction is terminated, the unreacted monomers are recovered, and the emulsion of perfluoroether fluororubber is obtained.

preparation example 3

[0046] A kind of perfluoroether fluorine rubber emulsion, the preparation method is as follows:

[0047] (1) 30L of deionized water was added to a 50L reactor, the reactor was evacuated, and when its oxygen content was less than or equal to 30ppm, 100g of perfluorooctanoic acid ammonia was added and heated to 90°C.

[0048] (2) feed intake according to the mol ratio of tetrafluoroethylene and perfluoromethyl vinyl ether as 65:35, the reactor pressure is raised to 2.8MPa, and 30g potassium persulfate, 10g 1,2-diiodoperfluoroethyl ether are added. Alkane and 60g I(CF 2 ) 2 OCF=CF 2 , carry out the polymerization reaction, when the amount of the reacted monomers is 10kg, the reaction is terminated, the unreacted monomers are recovered, and the perfluoroether fluororubber emulsion is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com